Coupler dismounting device

A technology of couplings and moving components, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as deformation, poor alignment of couplings, and influence on the transmission of shaft and axial force, etc., to achieve The effects of reducing hub deformation, improving maintenance efficiency, and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0035] In the present invention, unless otherwise stated, the used orientation words such as "up, down, left, and right" generally refer to up, down, left, and right in the drawings.

[0036] As known to those skilled in the art, couplings are widely used in various fields. The couplings involved in the present invention mainly refer to couplings in large motors, but are not limited thereto.

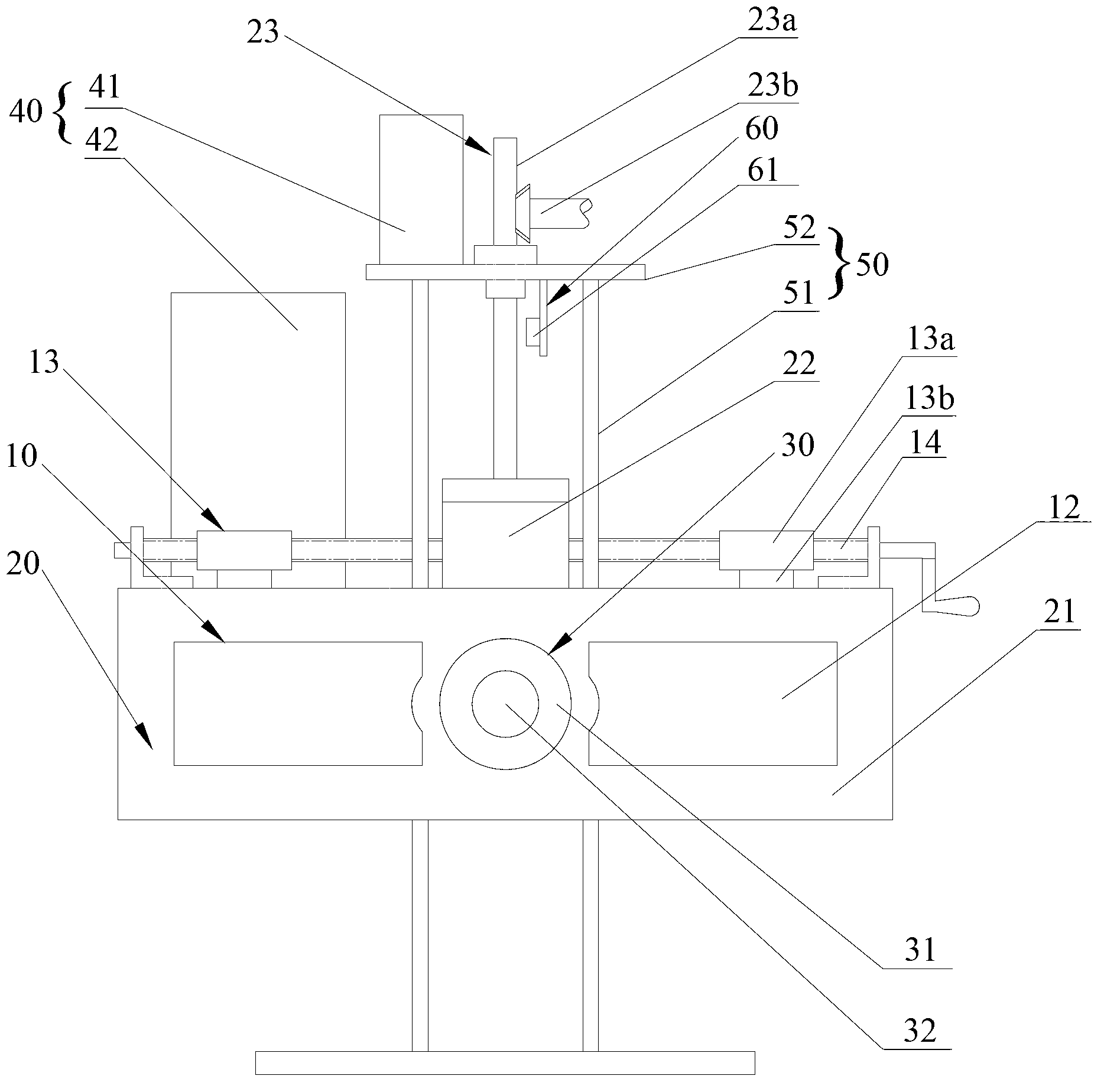

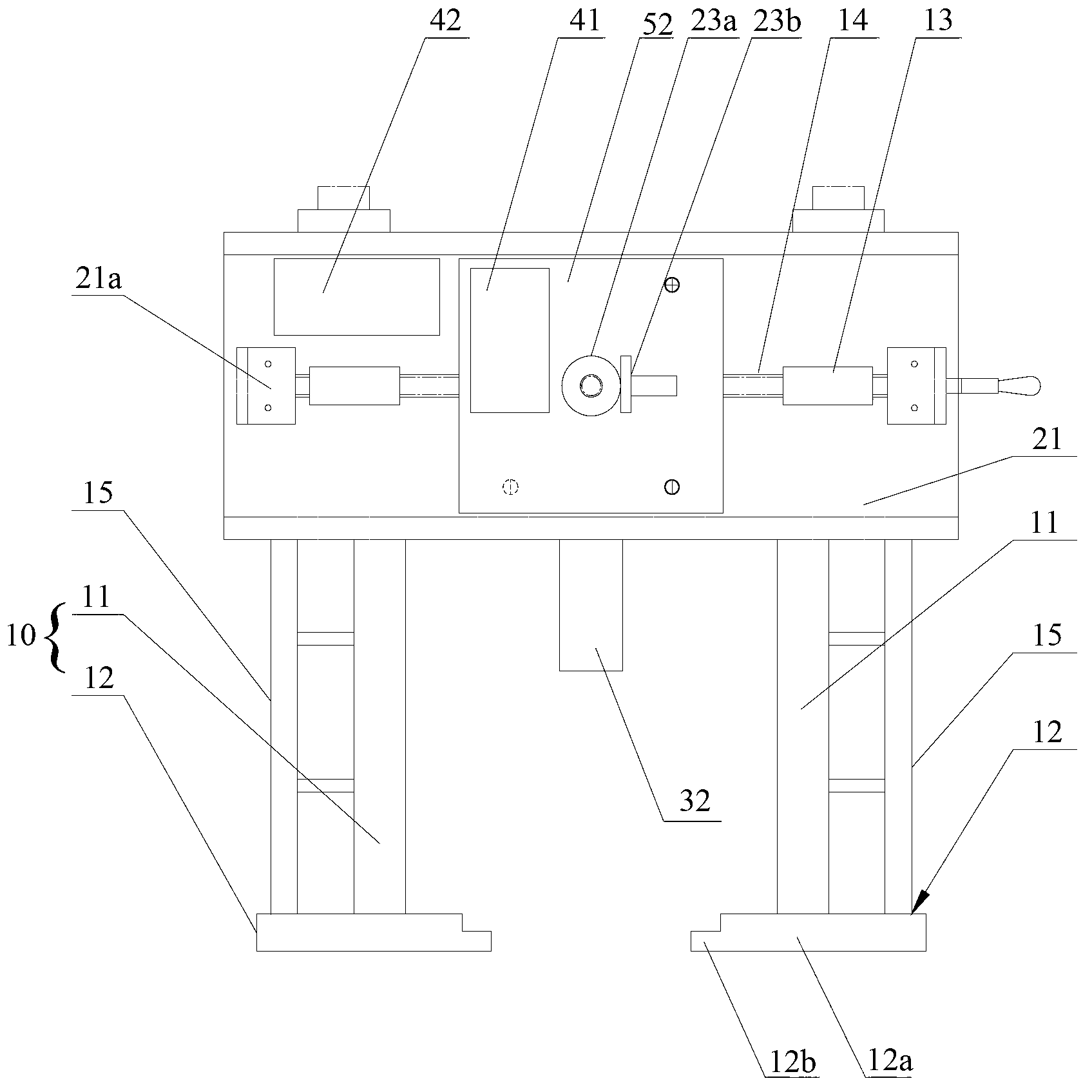

[0037] see figure 1 with figure 2 , The coupling removal device of the present invention mainly includes: a clamping assembly 10 , a moving assembly 20 , a telescopic assembly 30 and a control system 40 . Wherein, the clamping assembly 10 is used for clamping on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com