Hot-melt hemming method of water absorption paper

A technology of absorbent paper and edge wrapping, applied in the field of absorbent paper, can solve the problems of affecting the use effect and waste of resources, and achieve the effect of improving the use effect and reducing the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

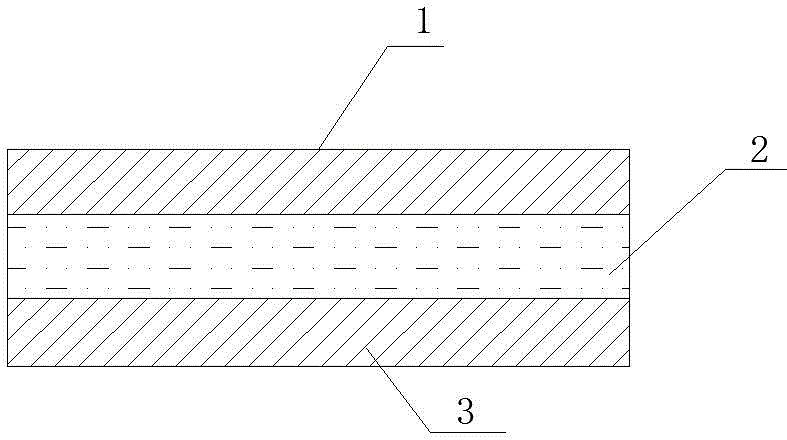

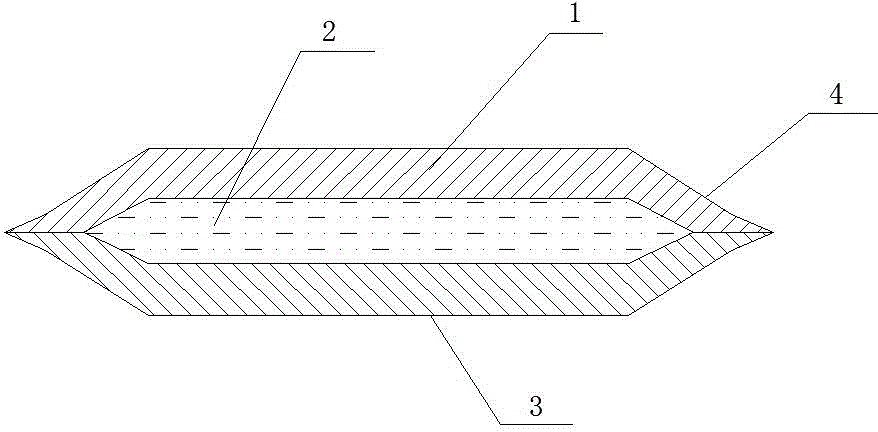

[0028] Reference figure 2 , An absorbent paper comprising a first dust-free paper layer 1, a non-woven fabric layer 2 located in the middle layer, and a second dust-free paper layer 3 located in the lower layer. The first dust-free paper layer The paper layer 1 and the second dust-free paper layer 3 are hot-melt bonded along the two sides of the non-woven fabric layer 2 to form an edge 4.

[0029] The hot melt bonding is carried out using the following equipment: Figure 4 , An absorbent paper cutting equipment, comprising a frame 5, on which a paper feed roller 6, a tension roller 7, an ultrasonic cutting machine and a winding device are sequentially arranged. Reference Figure 5 with 6 The ultrasonic cutting machine includes an ultrasonic generator 8, a cutting platform 9, a number of air cylinders 10 and cutting blades 11, and a drive motor. The ultrasonic generator 8 is arranged under the cutting platform 9, and the air cylinder 10 and the cutting blade 11 They are all loca...

Embodiment 2

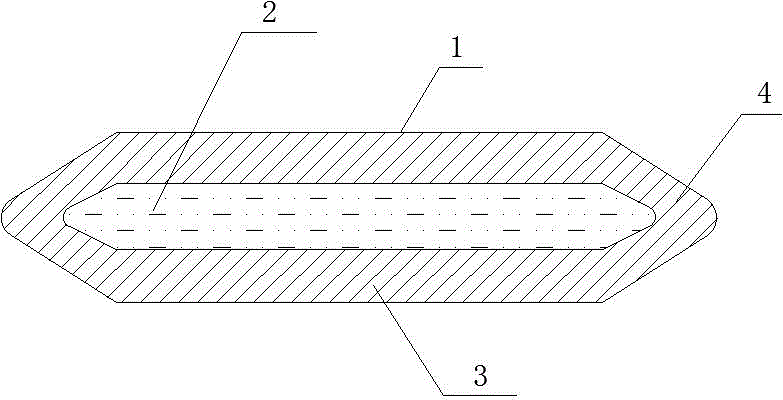

[0038] Reference image 3 , An absorbent paper comprising a first dust-free paper layer 1, a non-woven fabric layer 2 located in the middle layer, and a second dust-free paper layer 3 located in the lower layer. The first dust-free paper layer The paper layer 1 and the second dust-free paper layer 3 are connected along both sides of the non-woven fabric layer to form a hem 4. The first dust-free paper layer 1, the second dust-free paper layer 3, and the wrapping edge 4 form an integrated structure covering the dust-free layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com