C-shaped lifting appliance and appliance for lifting thrust wheel of excavating machine

A technology for excavators and spreaders, applied in the field of spreaders, can solve the problems of high labor intensity, easy removal of L-shaped spreaders, hidden dangers of safety, and low efficiency of manual handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

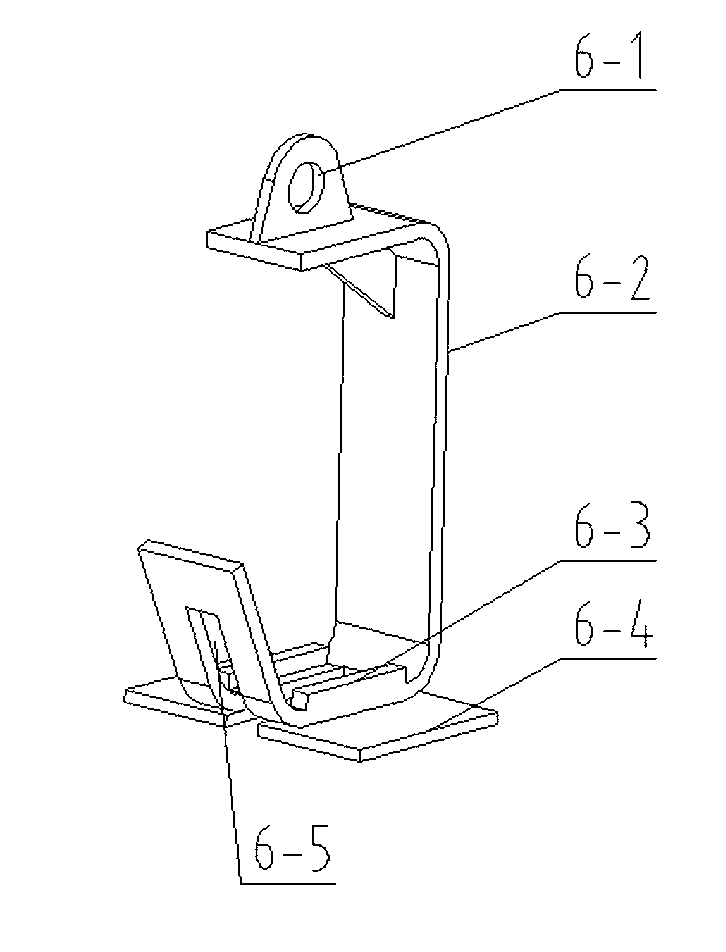

[0016] Such as figure 2 A C-type spreader is shown, including lug 6-1, main hanging plate 6-2, first limiting plate 6-3 and second limiting plate 6-4, and main hanging plate 6-2 has a certain The width of the C-shaped plate body, the middle part of the lower hook of the main hanging plate 6-2 is a flat plate, the middle of the flat plate is provided with a groove 6-5, and the groove 6-5 extends to the curved parts on both sides of the flat plate for a certain Length, the groove 6-5 can also not extend to the curved part, and the inner side of the flat plate of the main hanging plate 6-2 is located on both sides of the groove 6-5, respectively fixing a first limiting plate 6-3, Two first limiting plates 6-3 are arranged in the width direction of the main hanging plate 6-2, and a second limiting plate is respectively fixed on both sides of the groove 6-5 on the outer surface of the flat plate of the main hanging plate 6-2. Positioning plate 6-4, two second limiting plates 6-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com