Winding-free electroplating clamp of relay base

A technology for electroplating fixtures and relays, applied in the electrolysis process, electrolysis components, etc., can solve the problems of affecting the sealing performance of glass insulators, the terminal is easily damaged and deformed, and the production efficiency is low, so as to avoid poor contact, protect from deformation, and install The effect of convenient gripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

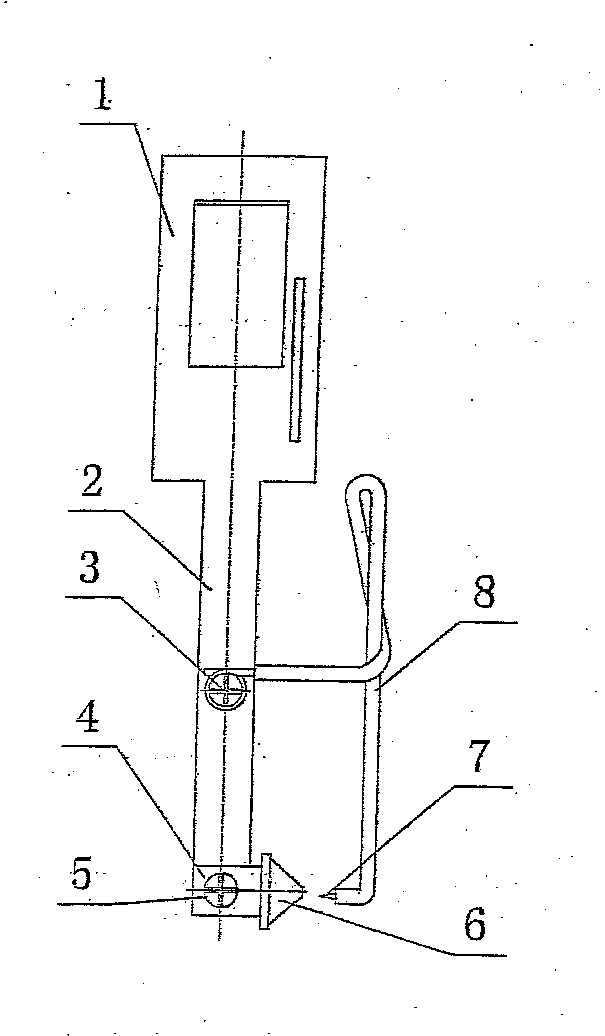

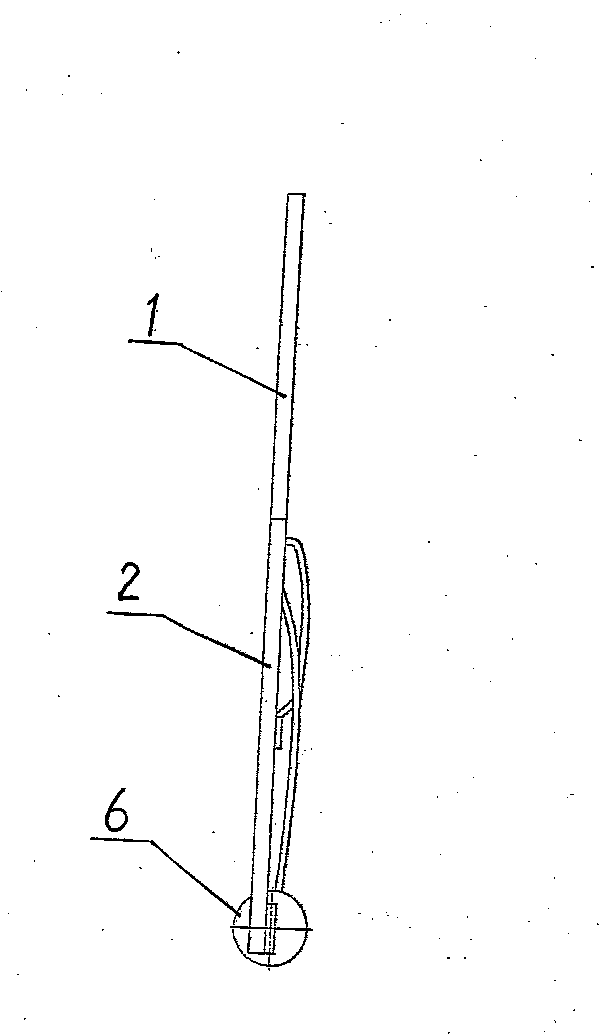

[0011] Specific implementation method: as shown in the figure, the conductive head 6 and the conductive head fixing block 4 are integrated and processed, and the conductive head fixing block 4 is fixed on the upper clamping block 1 and the lower clamping block 2 of the integrated processing with screws 5 On the lower end of the lower clamping block 2, fix the spring clamp 7 equipped with the polytetrafluoroethylene tube 8 on the lower clamping block 2 with screws 3, and then insulate the lower clamping block 2 and the conductive head fixing block 4, Then the whole fixture is fixed on the fully automatic production line by the upper clamping block 1, and then the relay base is mounted on the fixture to implement electroplating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com