Oil quantity adjustment device

A fuel volume adjustment and oil needle technology, which is applied in the field of aero-engines, can solve the problems of too thick mixed oil and gas, engine power drop, etc., and achieve the effects of reasonable air-fuel ratio, reduced reduction range, and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

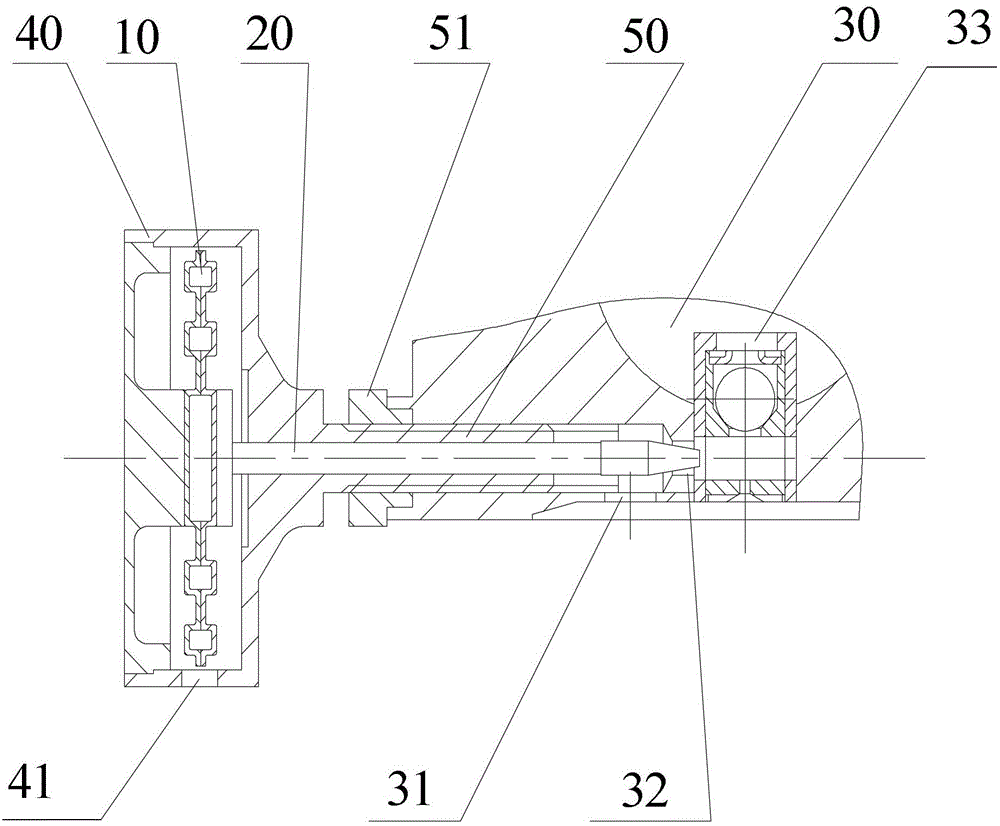

[0021] see figure 1 , according to the oil volume regulating device of the present invention, comprising: bellows 10, has bellows cavity, and gas is contained in bellows cavity; The carburetor 30 is provided with an oil supply valve 31 and a valve hole 32 communicating with the oil supply valve 31 , and the oil needle 20 can be movably inserted into the valve hole 32 and matched with the oil supply valve 31 . With the change of the working height of the engine, the bellows 10 is deformed due to the change of atmospheric pressure, and the oil needle 30 moves correspondingly with the deformation of the bellows 10, so that the size of the valve hole 32 of the carburetor can be automatically adjusted to further control The amount of fuel supplied makes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com