Three-way square joint for pipe connection

A technology of tee joint and square joint, which is used in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of detachment, easy softening, melting, poor toughness, etc. The effect of low cost and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

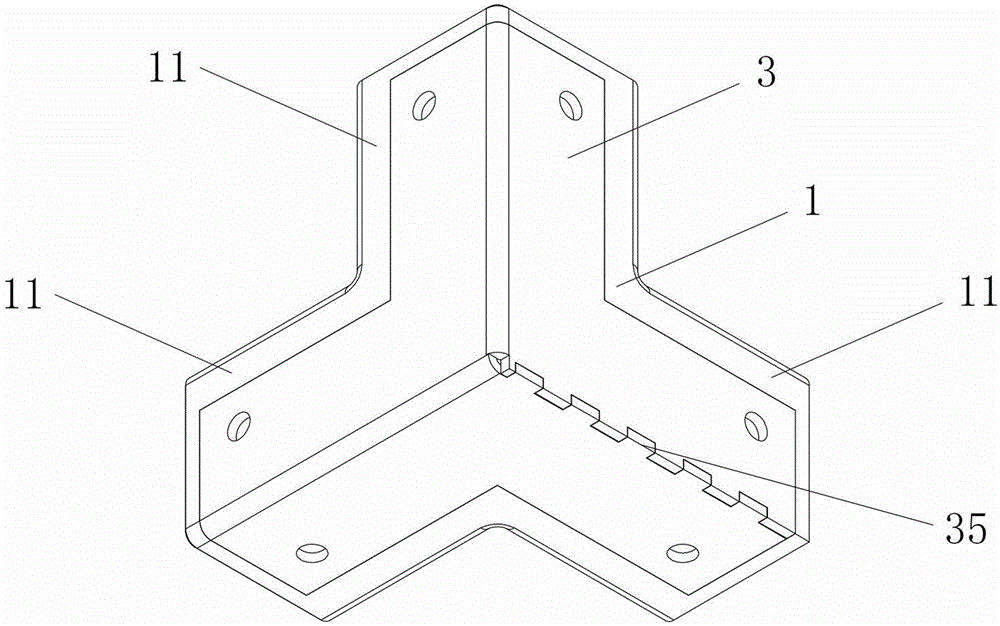

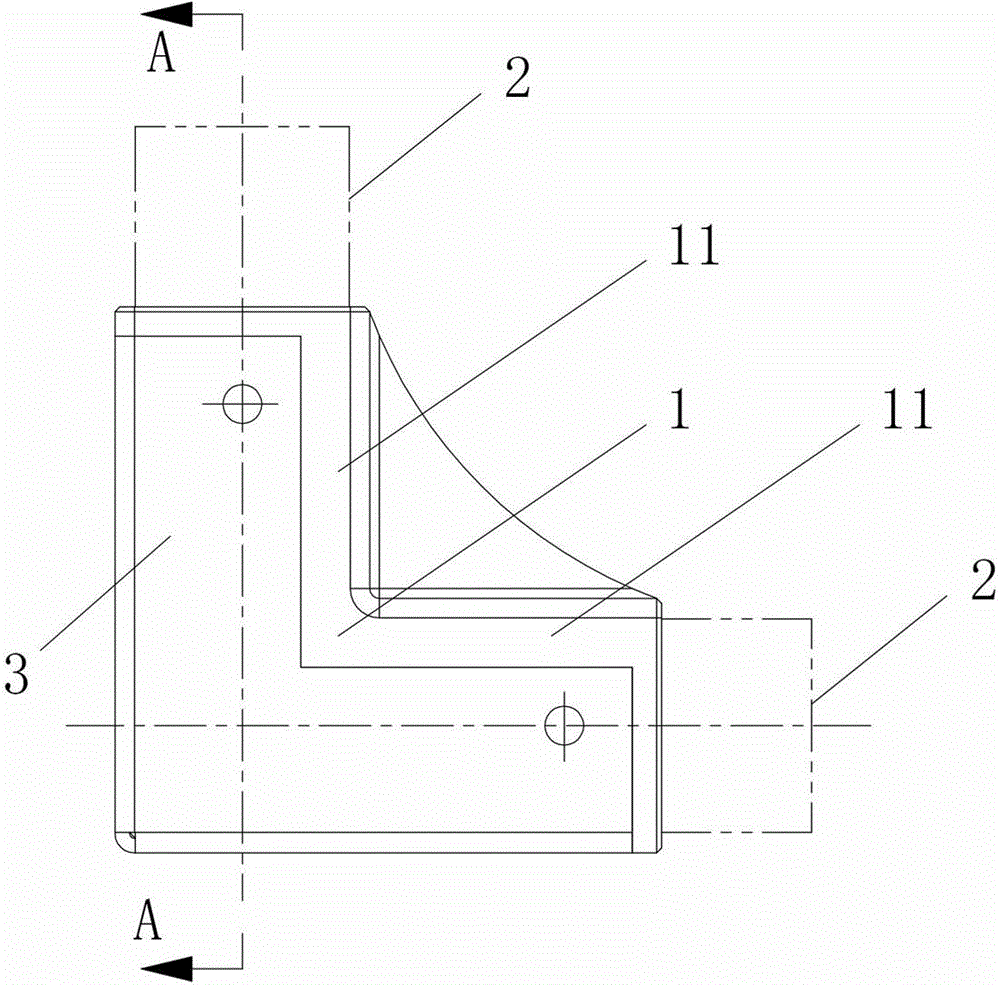

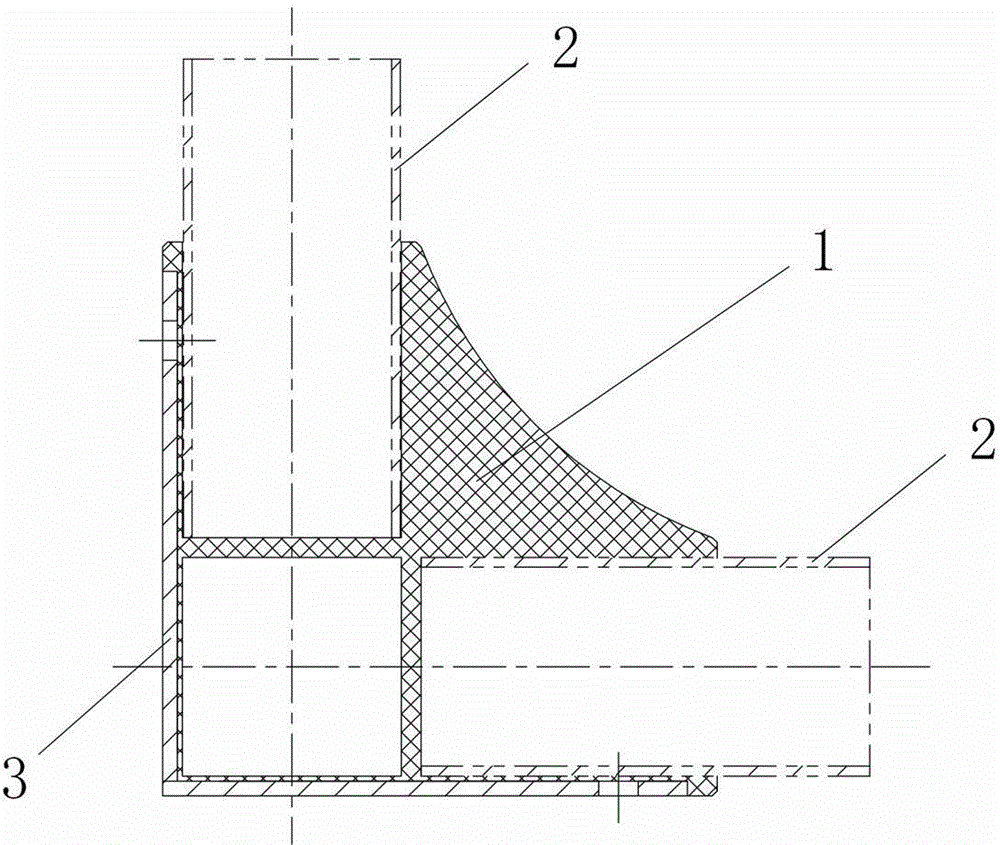

[0024] Figure 1 to Figure 4 It shows an embodiment of a three-way square joint for pipe connection of the present invention, the three-way joint includes a three-way joint body 1, and the three-way joint body 1 is provided with three sections of square joints 11 for connecting pipes 2, each The square joint 11 is provided with an inner hole for the insertion of the pipe material 2. The outer side of the tee joint body 1 is covered with an integral metal plate 3 extending to the three-section square joint 11 along three long edges. When installing, the pipe material 2 is inserted into the square joint In the inner hole of 11, the integral metal plate 3, the tee joint body 1 and the pipe 2 are connected and fastened by fasteners. In the present invention, the strengthening effect of the integral metal plate 3 on the tee square joint is doubled, greatly improving Improve the connection strength, bearing capacity and bending resistance; at the same time, the three-way square join...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap