Motor head gear train belt tightener

A front-end gear train and tensioner technology, which is applied to belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of high cost, troublesome adjustment of belt tension, and increase of pulley wrapping angle, etc. The effect of high cost, increased maintenance difficulty and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

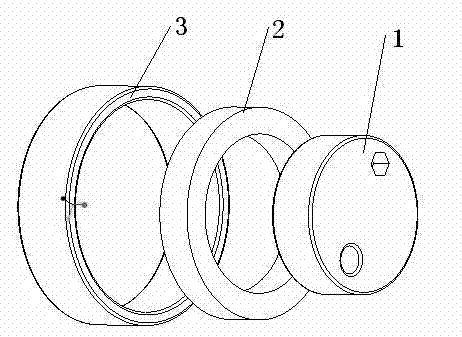

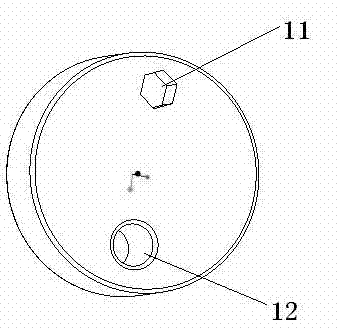

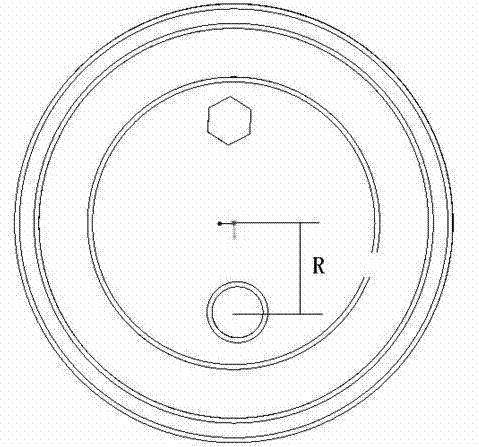

[0011] see figure 1 , the present invention is composed of a mandrel 1, a bearing 2 (due to the existing common structure, it is only schematically expressed in the figure, and the inner and outer rings are not clearly drawn) and a pulley 3, and the inner rings of the mandrel 1 and the bearing 2 are made of The pulley 3 and the outer ring of the bearing 2 are connected together by an interference fit. A bolt connection hole and an adjustment hole are distributed on the mandrel 1, and the bolt connection hole 12 is set eccentrically. The bolt connection hole 12 is a round hole, and the adjustment hole 11 is a hexagonal blind hole.

[0012] When the mandrel 1 is tightened by the bolts passing through the bolt connection hole 12 on the mandrel, the mandrel 1 and the inner ring of the bearing 2 are fixed together, and the outer ring of the bearing 2 rotates together with the pulley 3 under the drive of the belt 7, as figure 2 shown. Wherein the feature of each component is: a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com