Seal tension spring

A tension spring and sealing ring technology, applied in the field of tension springs, can solve the problems of short service life, product corrosion and corrosion, and achieve the effect of long service life and wide application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

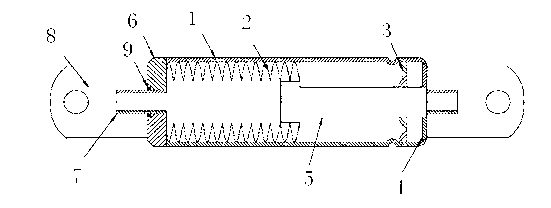

[0010] A kind of sealing extension spring of the present invention, see figure 1 , the sealing tension spring includes a tension spring 1 and an outer tube 2, the tension spring 1 is arranged in the outer tube 2; The front end is connected with the shaft 5; the bottom of the shaft 5 is provided with a step 51, and the front end of the extension spring 1 is fixed on the bottom of the shaft 5 through the step 51. A tailstock 6 is provided at the rear of the outer tube 2, and the rear end of the extension spring 1 is connected with the outer tooth connecting rod 7, and the outer tooth connecting rod 7 extends to the outside of the tailstock 6 and is connected with the inner tooth connecting sleeve 8; A sealing ring 9 is provided between 7 and the tailstock 6 .

[0011] The invention has good sealing effect, is not affected by environmental factors during use, does not rust and corrode, has long service life and wide application fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com