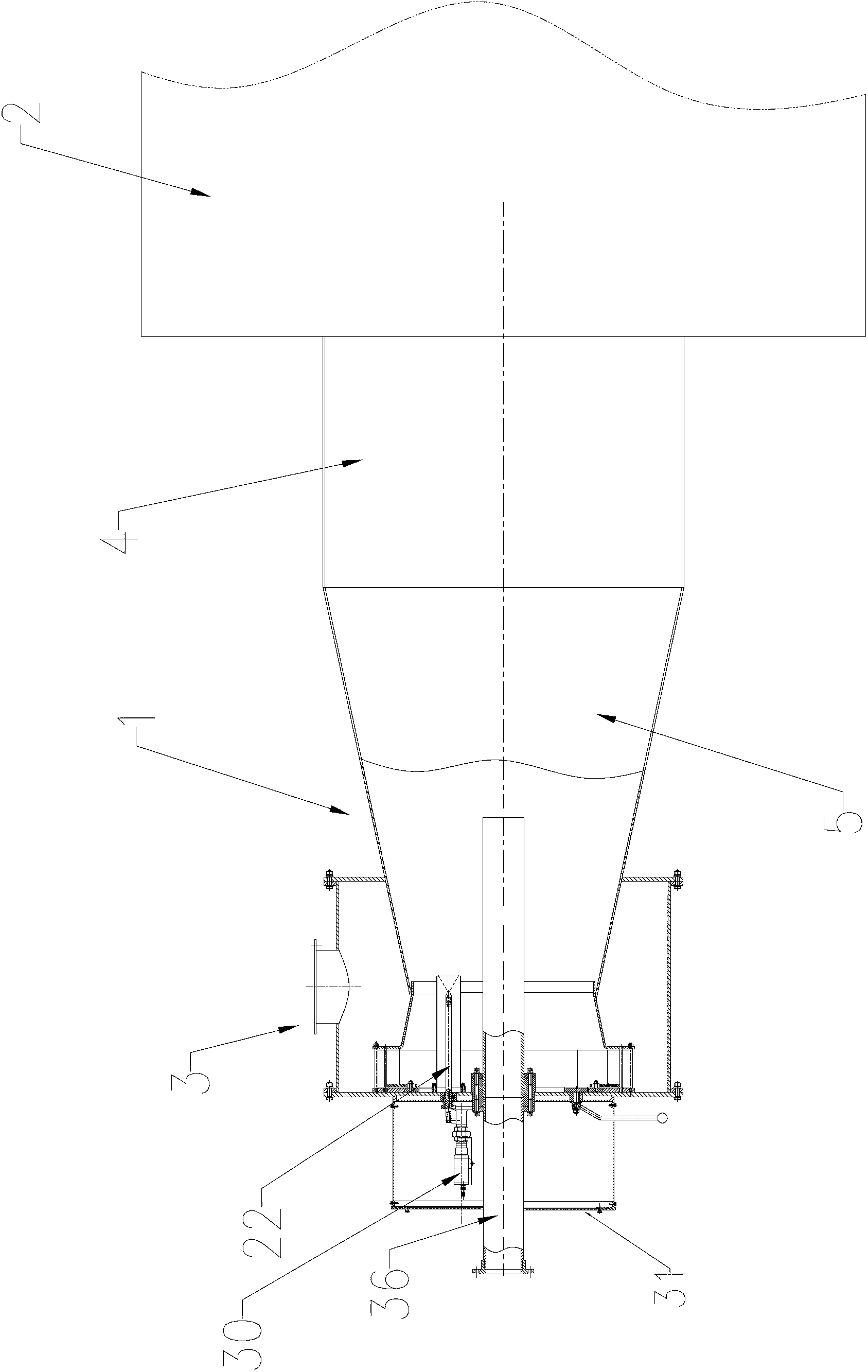

Pulverized coal burner

A pulverized coal burner and pulverized coal technology are applied in the direction of burners, burners for burning powder fuel, and combustion methods, etc., which can solve the problems of high thermal power of igniters, potential safety hazards, waste of resources, etc., and achieve reduction of thermal power, The effect of preventing deflagration and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

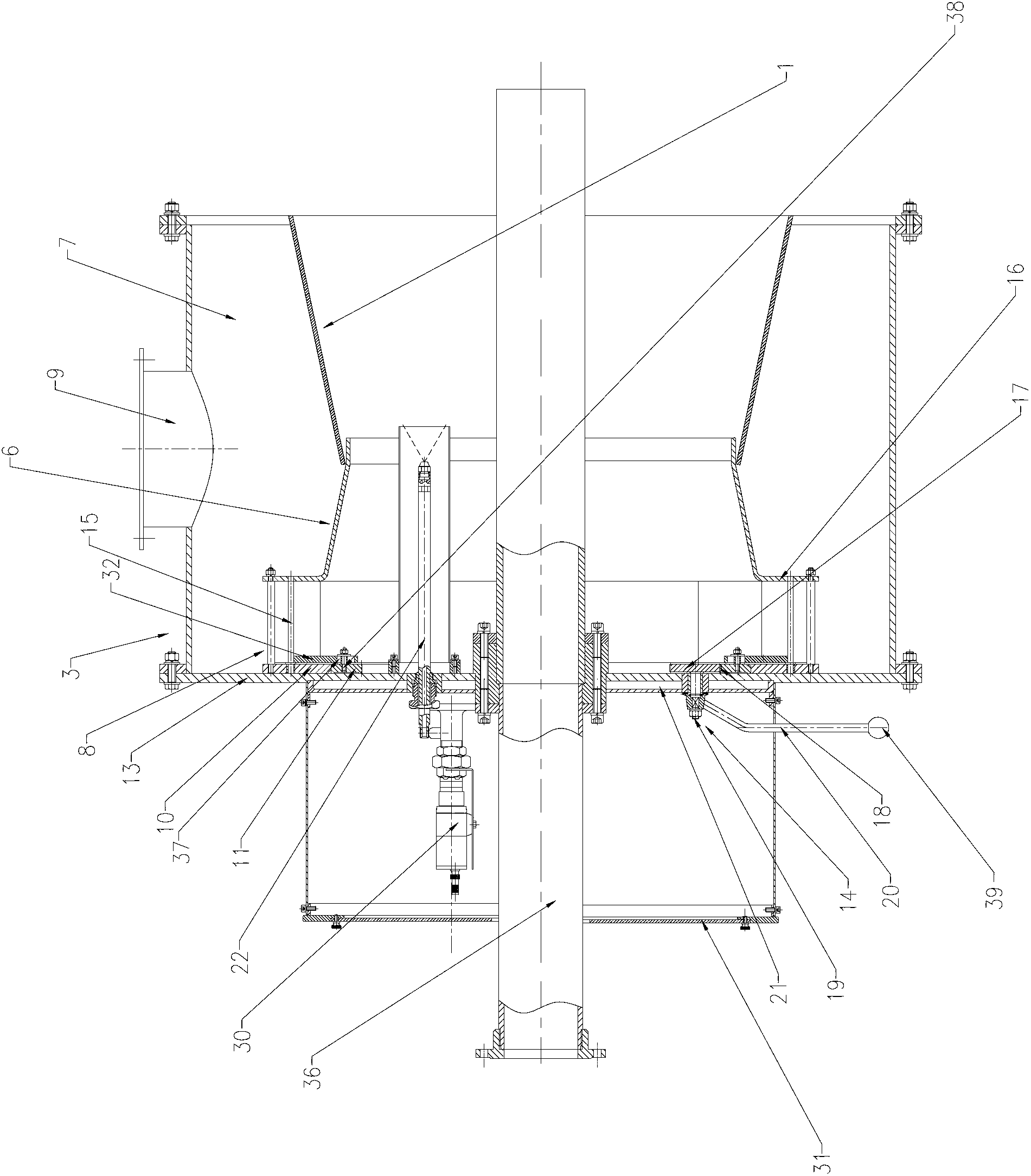

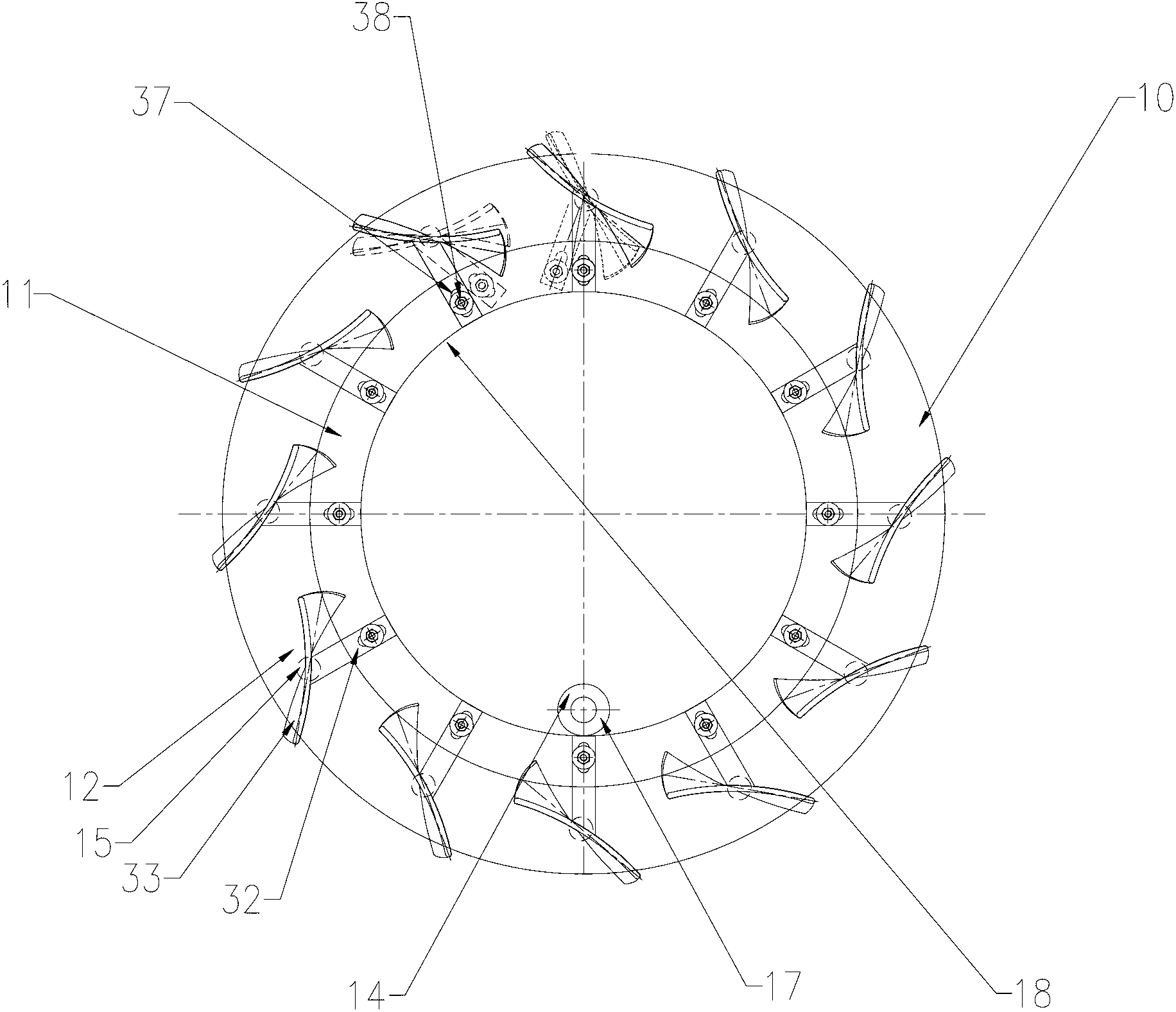

[0053] According to a preferred embodiment of the present invention, the end plate 13 is provided with a water-cooled interlayer 21 . In this way, the sensors and electrical components inserted through the end plate 13 can be cooled through the water-cooling interlayer 21 to prevent them from being damaged.

[0054] The igniter 22 can take various suitable configurations. According to a preferred embodiment of the present invention, the igniter 22 includes an ignition air gun 23 and an oil gun 24 . In this way, the liquefied gas can be ignited by the ignition air gun 23 first, and after the liquefied gas is ignited, the oil gun 24 is sprayed, and the secondary flame is co-combusted in the pre-combustion chamber 1 under the condition of swirling air distribution, and the flame is full of the entire pre-combustion chamber. Room 1 starts to supply pulverized coal when the conditions are ripe. In this way, the two-stage ignition technology of gas and oil is adopted, and the igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com