Automatic pump and an operation control method for the same

An automatic pump and control unit technology, applied in pump control, engine control, AC motor control, etc., can solve the problems of increasing the size of the automatic pump, high inverter, increasing the manufacturing cost of the automatic pump, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of an automatic pump and an operation control method thereof according to the present invention will be described with reference to the accompanying drawings.

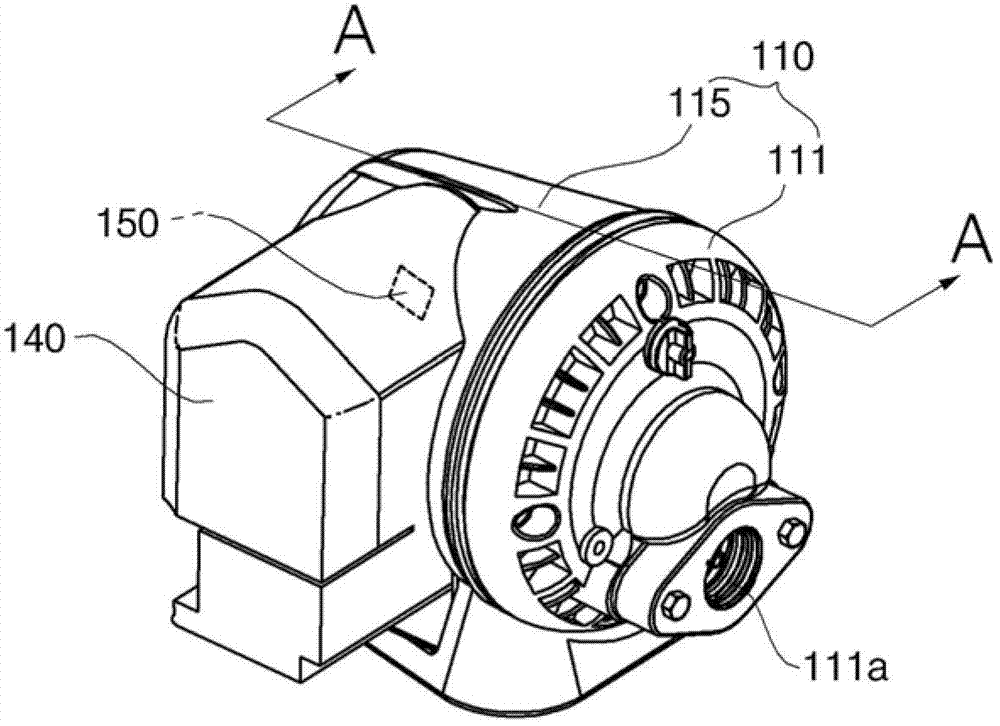

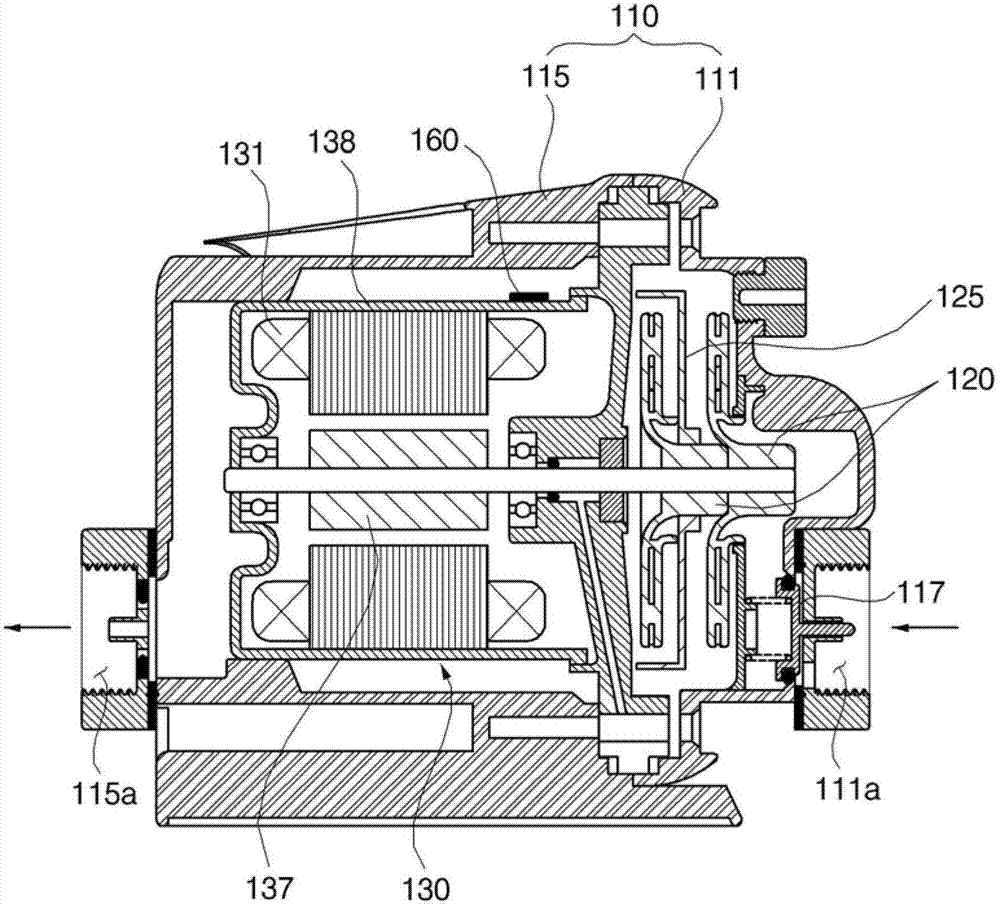

[0023] figure 1 is a perspective view of an automatic pump according to an embodiment of the present invention, figure 2 is along figure 1 A cross-sectional view taken along line A-A.

[0024] As shown, according to the present embodiment, the automatic pump includes a housing 110 having a first housing portion 111 and a second housing portion 115 connected to each other.

[0025] Formed respectively on opposite sides of the housing 110 are an inlet 111a for communication with a liquid source, such as water, and an outlet 115a for communication with an application site, such as a cock. More specifically, the inlet 111 a is formed at the first housing part 111 , and the outlet 115 a is formed at the second housing part 115 .

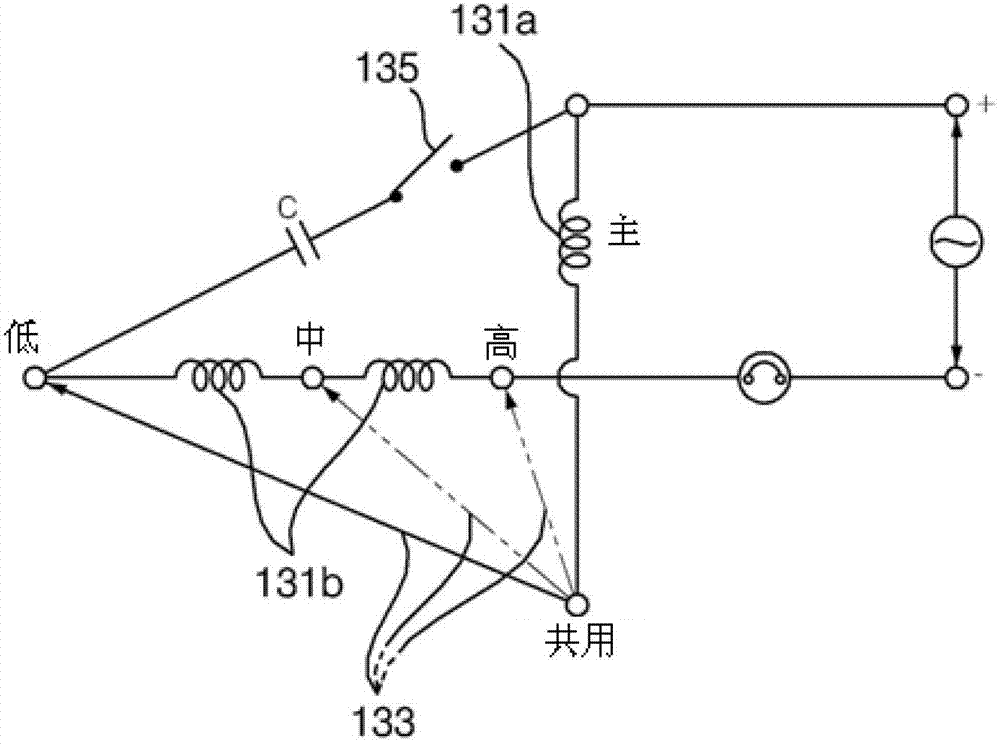

[0026] In the housing 110, the pump impeller 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com