Gas insulated switchgear

A technology of gas-insulated opening and closing and container, which is applied in the direction of switchgear, setting of switchgear, setting of switchgear with metal casing, etc., which can solve the problem of peeling off of low-friction materials, increased friction, and scattering of lubricating paste or lubricating oil or deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below with reference to the drawings.

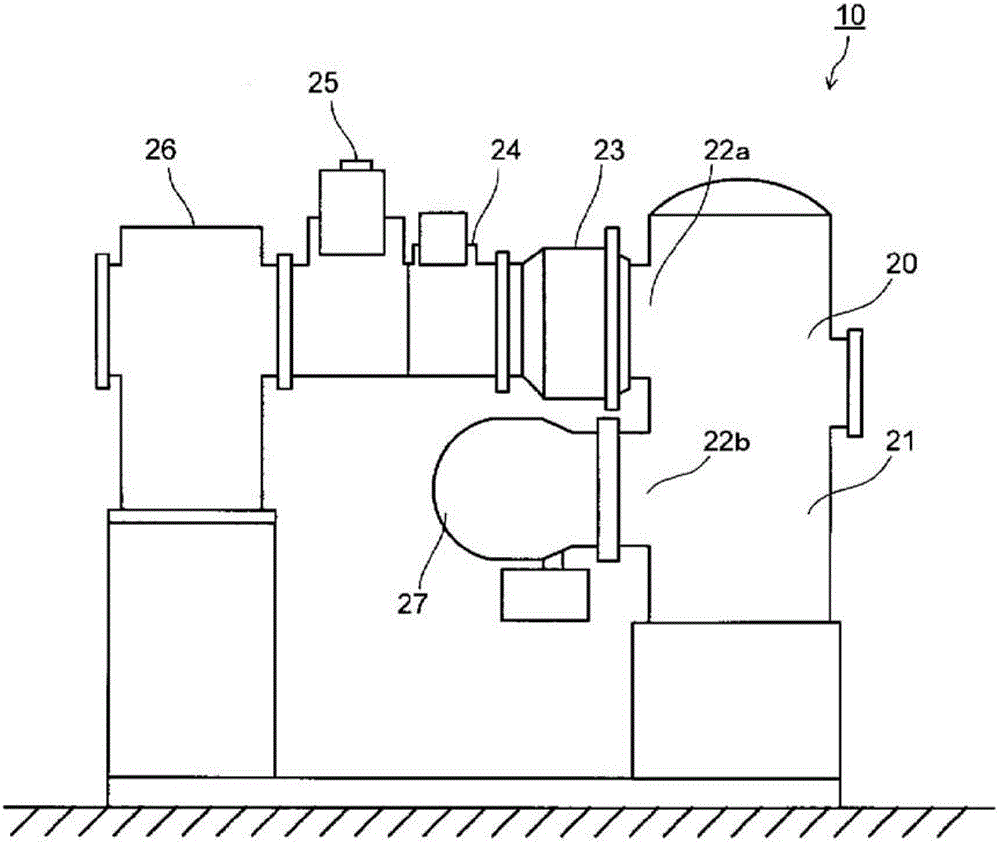

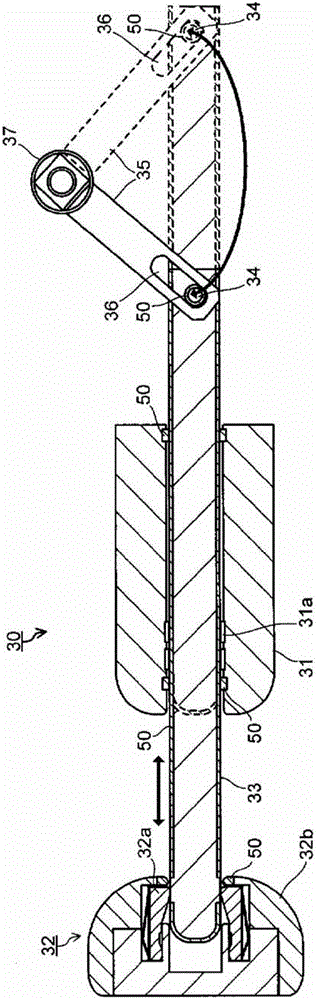

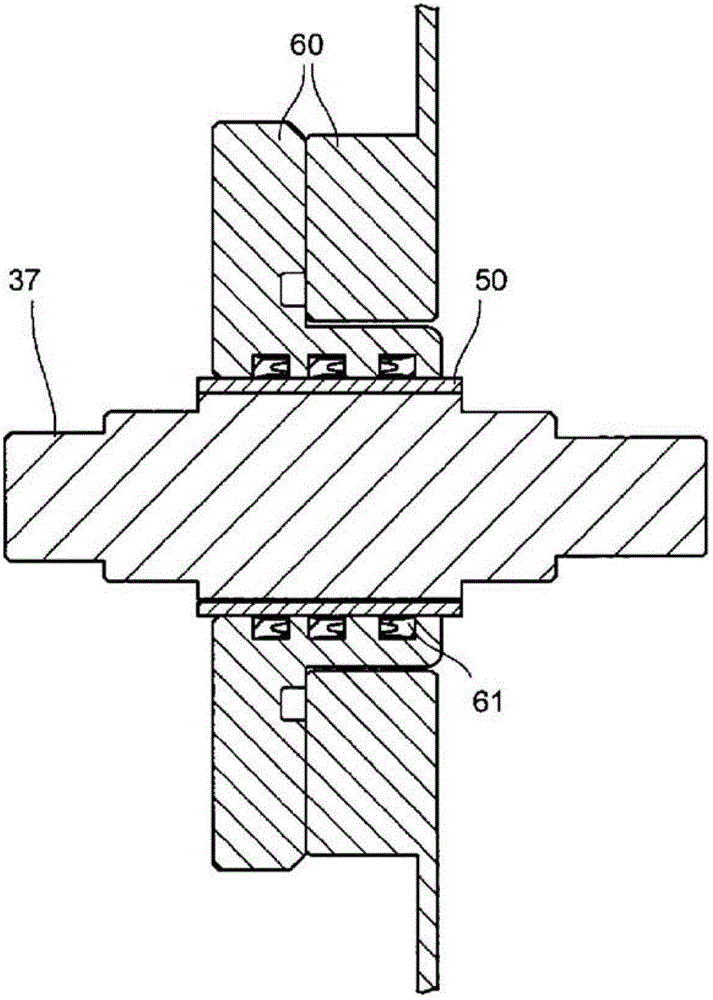

[0023] figure 1 It is a side view showing the configuration of the gas insulated switchgear 10 according to the embodiment of the present invention. figure 2 It is a figure which shows the cross section of the breaking part 30 inside the bus-bar integrated circuit breaker 27. image 3 It is a figure which shows the cross section of the shaft 37 which rotates the lever member 35 which drives the movable contactor 33. As shown in FIG.

[0024] like figure 1 As shown, in the gas insulated switchgear 10, the circuit breaker 20 is installed such that the axis of the container 21 is perpendicular to the mounting surface. A current transformer 23 is provided at an upper outlet portion 22 a of the breaker 20 , and is connected to a cable distribution box 26 via a circuit breaker 24 and a ground switch 25 . In addition, the lower outlet portion 22 b of the breaker 20 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com