Fragrance fillet and manufacture method of fragrance fillet

A technology for fish fillets and auxiliary materials, which is applied in the field of food processing, can solve problems such as failure to achieve standardization, and achieve the effect of standardizing raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A kind of fragrant fish fillet and its preparation method

[0023] A fragrant fish fillet, said fragrant fish fillet is mainly made of 950-1050 parts by weight of main ingredient fish fillets and the following auxiliary materials by weight:

[0024] Starch 16~20 parts;

[0025] Chicken essence 1~2 parts;

[0026] Salt 8~10 parts;

[0027] MSG 4~6 parts;

[0028] Sodium bicarbonate 3~4 parts.

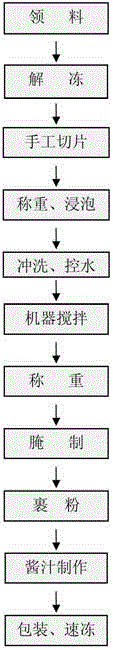

[0029] See attached figure 1 Shown, a kind of method of making fragrant fish fillet, described fish fillet adopts black fish fillet.

[0030] In a further preferred technical solution of the specific embodiment of the present invention, the main ingredient fish fillets and auxiliary materials are stirred according to the process ratio, pickled at 0-5°C for 2-3 hours, and then the pickled fish fillets are Coating operation, and simultaneous making sauce.

[0031] In a further preferred technical solution of the specific embodiment of the present invention, the ...

Embodiment 2

[0036] Embodiment 2: A kind of fragrant fish fillet and its preparation method

[0037] A kind of fragrance fish fillet, the batching of described fragrance fish fillet is as follows:

[0038] 1000g fish fillet

[0039] 18 grams of starch;

[0040] Chicken essence 1g;

[0041] Salt 9 grams;

[0042] MSG 5 grams;

[0043] Sodium bicarbonate 3 grams.

[0044] See attached figure 1 As shown, the method for making fragrant fish fillets, the steps are as follows:

[0045] 1. Picking material: raw material: black fish fillet. Confirm the quantity of black fish fillets, whether they have deteriorated and have peculiar smell.

[0046] 2. Thawing: Thaw the black fish fillets received naturally. Thawing standard: There is no frozen ice in the black fish fillet, and it is completely thawed.

[0047] 3. Manual slicing: black fish fillets are cut into lengths and widths of 3.5-4 cm, and the weight is 8-10g. Slicing standard: Uniform size, no continuous knife phenomenon.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com