Method for simultaneously removing magnesium oxide, ferric oxide and aluminum oxide sesquioxide in middle-grade and low-grade phosphate ores by adopting double-reverse flotation process

A double reverse flotation and iron oxide technology, applied in flotation, solid separation, etc., can solve the problems of high beneficiation cost, high impurity content, large collector consumption, etc., and achieve the effect of reducing production cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

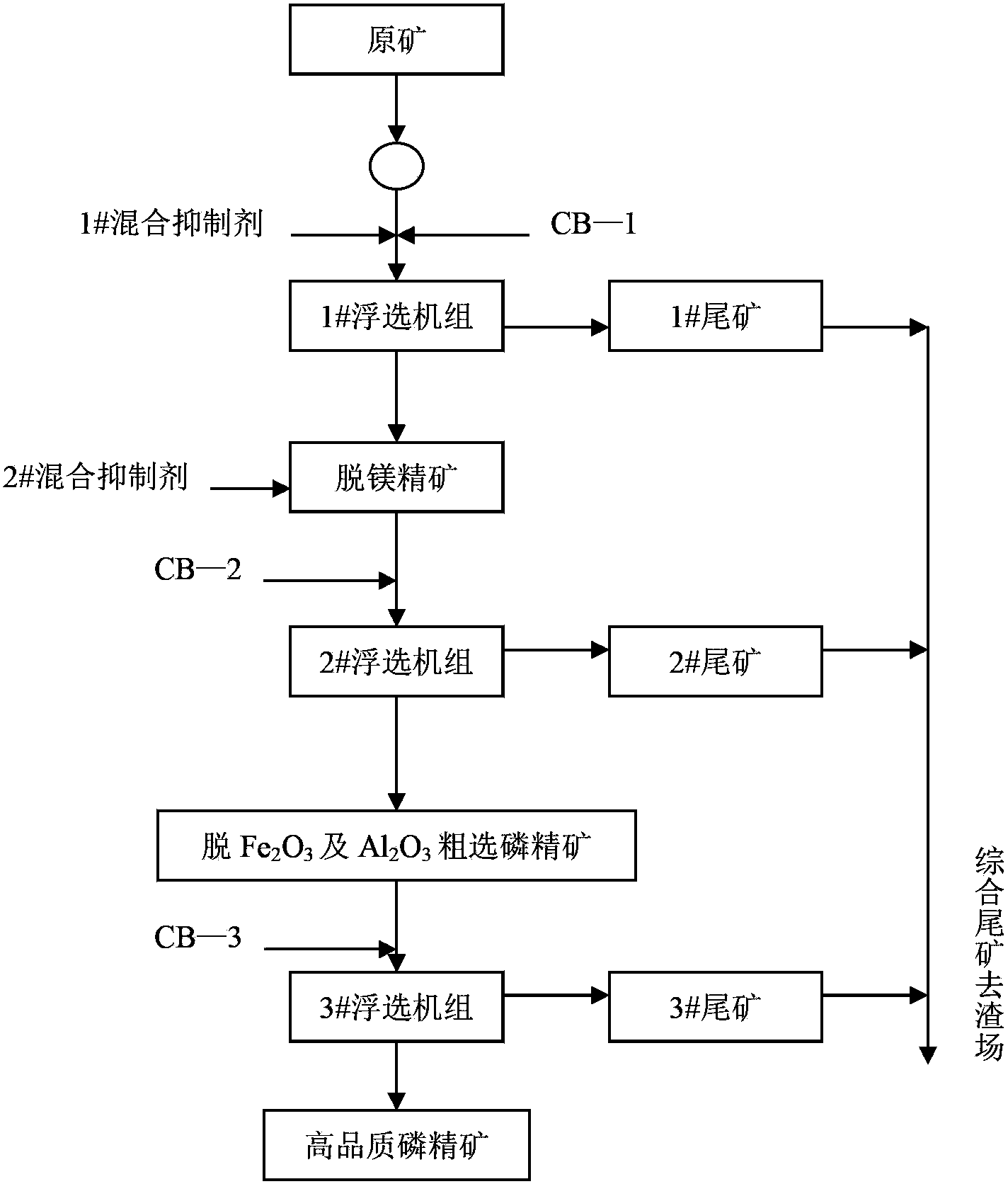

[0018] A method for simultaneously removing magnesium oxide, iron oxide and aluminum oxide sesquioxide from medium and low-grade phosphate rock by double reverse flotation process, see figure 1 , proceed as follows:

[0019] will contain P 2 o 5 The mass percentage is 23-25%, the MgO mass percentage is 3-4%, and the Fe 2 o 3 and Al 2 o 3 The mass percentage is 4-5% of the phosphate rock ground to -200 mesh 85-90%, and the slurry with a solid content of 20-25%;

[0020] Add 1# mixed inhibitor, stir well, and adjust the PH value of the pulp to 4.0-4.5; 1# mixed inhibitor is a mixed acid with a concentration of 5-15% fluosilicic acid and a concentration of 50% sulfuric acid in a mass ratio of 1:1;

[0021] The adjusted pulp is introduced into the flotation machine, and the collector CB-1 is added at the same time. CB-1 is a mixture of sodium oleate, sodium linoleate and sodium stearate in a mass ratio of 1:1:1. The dosage is 400g / T, after inflating and foaming, the demagne...

Embodiment 2

[0025] A method for simultaneously removing magnesium oxide, iron oxide and aluminum oxide sesquioxide from medium and low-grade phosphate rocks by double reverse flotation process, which is operated and processed according to the following steps:

[0026] will contain P 2 o 5 The mass percentage is 22-24%, the MgO mass percentage is 5-6%, and the Fe 2 o 3 and Al 2 o 3 The phosphate rock with a mass percentage of 3-5% is ground to -200 mesh 90-95%, and the slurry with a solid content of 30-35%.

[0027] Add 1# mixed inhibitor, stir well, adjust the PH value of the slurry to 4.5-5.0;

[0028] 1# mixed inhibitor is a mixed acid with a concentration of 5-15% fluosilicic acid and a concentration of 50% sulfuric acid (mass ratio is 1:1);

[0029] Introduce the adjusted pulp into the flotation machine, and add collector CB-1 at the same time, CB-1 is a mixture of sodium oleate, sodium linoleate, and sodium stearate (mass ratio 1:1:1), and its dosage It is 500g / T, and after in...

Embodiment 3

[0034] A method for simultaneously removing magnesium oxide, iron oxide and aluminum oxide sesquioxide from medium and low-grade phosphate rocks by double reverse flotation process, which is operated and processed according to the following steps:

[0035] will contain P 2 o 5 The mass percentage is 23-26%, the MgO mass percentage is 4-5%, and the Fe 2 o 3 and Al 2 o 3 The phosphate rock with a mass percentage of 5-6% is ground to -200 mesh 90-95%, and the pulp with a solid content of 25-30%.

[0036] Add 1# mixed inhibitor, stir well, and adjust the PH value of the pulp to 4.0-4.8; 1# mixed inhibitor is a mixed acid with a concentration of 5-15% fluosilicic acid and a concentration of 50% sulfuric acid in a mass ratio of 1:1;

[0037] The adjusted pulp is introduced into the flotation machine, and the collector CB-1 is added at the same time. CB-1 is a mixture of sodium oleate, sodium linoleate and sodium stearate in a mass ratio of 1:1:1. The dosage is 600g / T, after in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com