Double-beam hoist-type anti-collision safety protection device for crane

A safety protection device, crane technology, applied in safety devices, transportation and packaging, load hanging components, etc., can solve problems such as hidden safety hazards, failure to protect offices, crane hooks hitting buildings, etc., to avoid losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

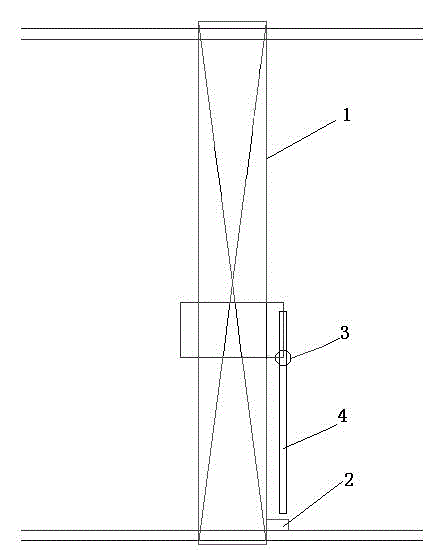

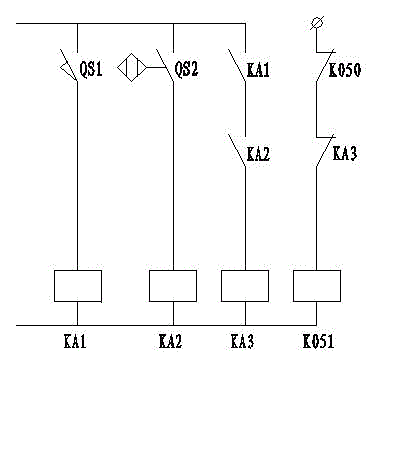

[0015] Embodiment: A kind of anti-collision safety protection device of double girder hoist crane (see figure 1 , figure 2 ), which includes a crane 1, a cross safety limit switch QS1 2 is installed on the end beam of the crane 1, and a square steel pipe 4 is arranged on the girder of the crane 1, and the length of the square steel pipe 4 is 0-2 longer than the front length of the building in the workshop m, the hoist trolley of the crane 1 is equipped with a proximity switch QS2 3, the proximity switch QS2 3 is installed on the hoist trolley of the crane and moves with the hook, the proximity switch QS2 3 and the square steel pipe 4 are on the same vertical plane, and are located on the square steel pipe 4 Above, the proximity switch QS2 3 is 2-4mm higher than the height of the square steel pipe 4 from the ground, so that when the proximity switch QS2 3 moves to the right top of the square steel pipe 4 with the hoist trolley (hook) of the crane, QS2 acts. The normally open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com