Overflow pipe and slurry tank using same

A technology of overflow pipe and slurry tank, which is applied in the field of rotatable overflow pipe and slurry tank using the overflow pipe, which can solve the problem of inconsistency in flow velocity of slurry, time-consuming and inability to match the ratio of downstream raw material formula and other issues to achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

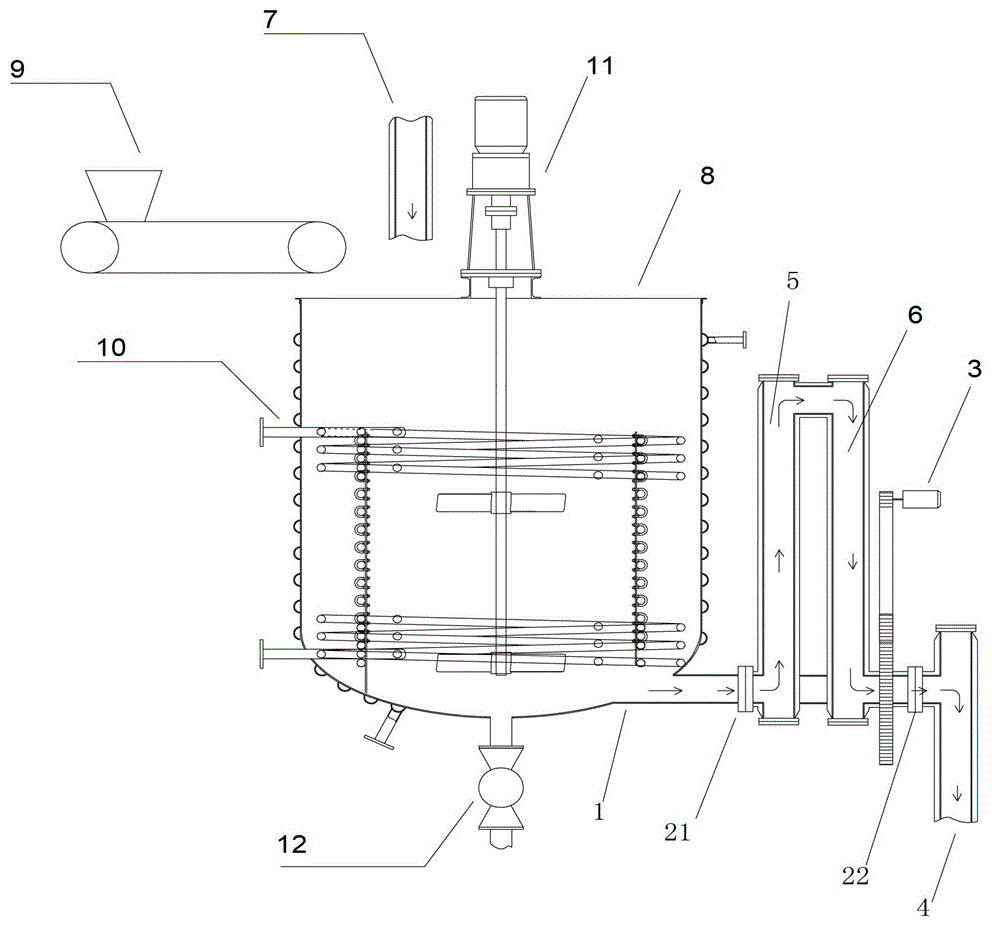

[0016] Examples of the present invention are figure 1 As shown, an overflow pipe includes an overflow main pipe 1, rotary sealing joints 21 and 22, a control structure and a discharge pipe 4, and the two ends of the overflow pipe are respectively provided with an overflow inlet pipe 5 and an overflow outlet pipe 6. The overflow inlet pipe 5 and the overflow outlet pipe 6 are respectively connected to the rotary sealing joints 21 and 22; the rotary sealing joint 21 of the overflow inlet pipe 5 is used to connect with the slurry tank 7, and the rotary sealing of the overflow outlet pipe 6 The joint 22 is used to connect with the discharge pipeline 4; the control structure is arranged at either end of the overflow pipe, and the control structure controls the rotation of the overflow main pipeline 1 according to the liquid level of the slurry in the slurry tank 7, so that the overflow main pipeline The level at the top of the pipeline 1 is equal to the liquid level of the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com