Core-shell metal oxide/titanium oxide compound electrorheological fluid and preparation method thereof

An electrorheological fluid and oxide technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of wide particle size distribution, insufficient anti-settling resistance, high yield stress, etc., and achieve low zero field strength and high field strength High strength and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Take by weighing 1.2g of iron oxide particles with a width of 30-40nm and a length of 500-700nm;

[0041] (2) Disperse iron oxide particles in 200mL sodium hydroxide aqueous solution (pH=10), add 1.1g polydiallyldimethylammonium chloride (PDDA) and stir for 1 hour, then wash and centrifuge out the iron oxide particles. iron particles;

[0042] (3) Dissolve 1.6 g of butyl titanate in a mixed solvent of 50 mL of acetonitrile / ethanol (volume ratio 1:3), and stir while adding dropwise until solution A is formed;

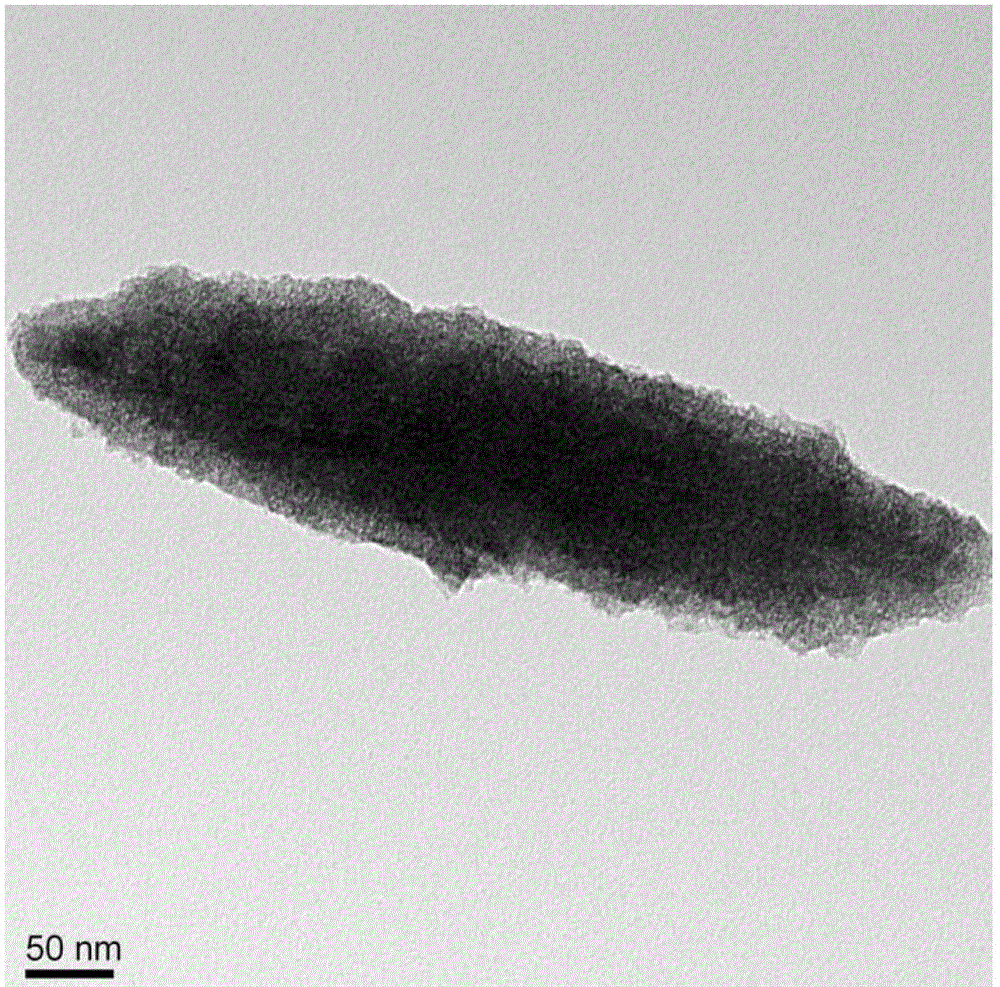

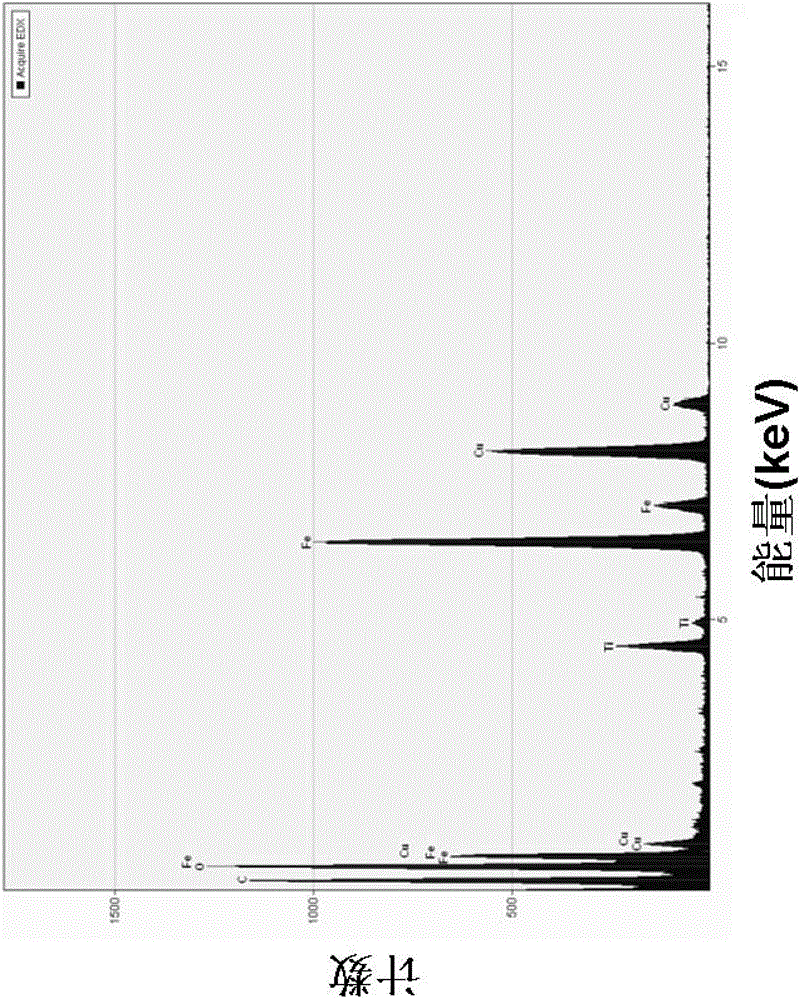

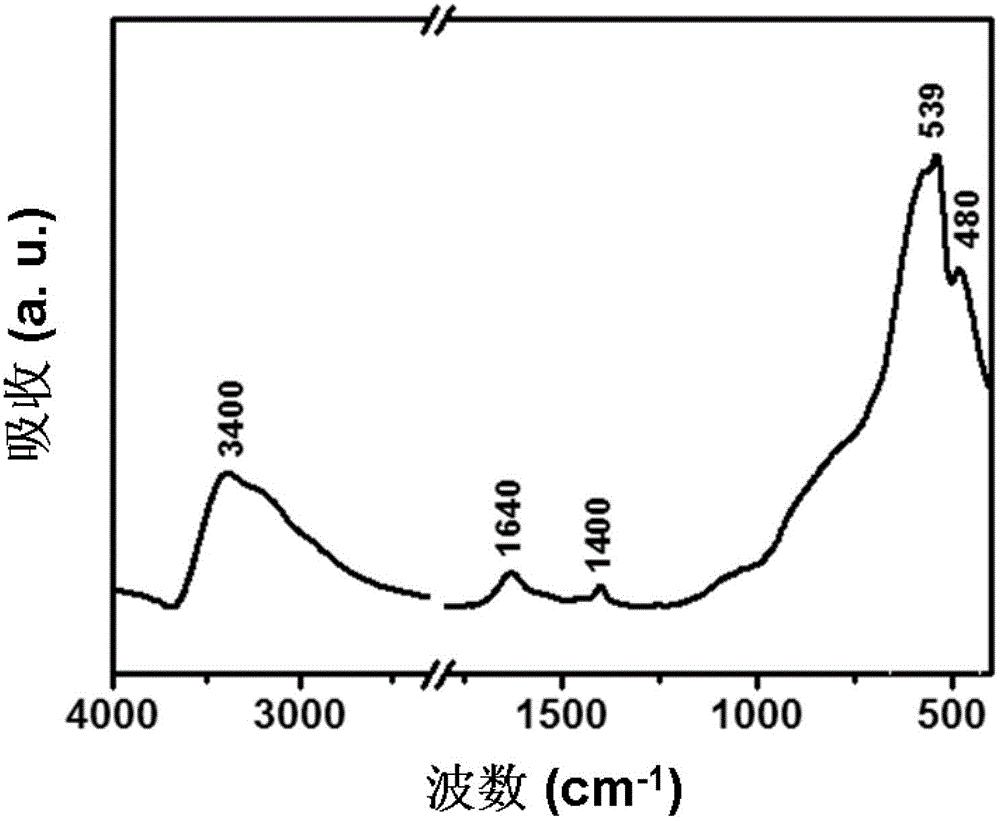

[0043] (4) Disperse the iron oxide particles treated in step 2 in a mixed solvent of 300 mL of acetonitrile / ethanol / water (volume ratio 1:3:0.04), then add solution A, age the resulting precipitate for 3 hours and then wash , centrifugation, and drying to obtain core-shell iron oxide / titanium oxide composite particles (TEM photo as figure 1 As shown, the EDS spectrum as figure 2 As shown, the IR spectrum as image 3 shown);

[0044] (5) Uniformly dispers...

Embodiment 2

[0046] (1) Weigh 1.0g of titanium oxide particles with a width of 18-22nm and a length of 60-90nm;

[0047] (2) Disperse the titanium oxide particles in 200 mL of ammonia solution (pH=8), add 1.4 g of hydroxypropyl cellulose (HPC) and stir for 1 hour, then wash and centrifuge out the titanium oxide particles;

[0048] (3) Dissolve 2.2 g of ethyl titanate in a mixed solvent of 60 mL of acetonitrile / ethanol (volume ratio 1:4), and stir while adding dropwise until solution A is formed;

[0049] (4) Disperse the titanium oxide particles treated in step 2 in a mixed solvent of 360 mL of acetonitrile / ethanol / water (volume ratio 1:4:0.08), then add solution A, age the resulting precipitate for 5 hours and then wash , centrifuging, and drying to obtain core-shell titanium oxide / titanium oxide composite particles;

[0050] (5) Uniformly disperse the core-shell titanium oxide / titanium oxide composite particles obtained in step 4 in methyl silicone oil (mass fraction 52%) to obtain a co...

Embodiment 3

[0052] (1) Weigh 1.5g of zinc oxide particles with a width of 450-600nm and a length of 2.5-3.5 μm;

[0053] (2) Disperse zinc oxide particles in 200mL potassium hydroxide aqueous solution (pH=11), add 1.0g polydiallyldimethylammonium chloride (PDDA) and stir for 1 hour, then wash and filter out zinc oxide particles;

[0054] (3) Dissolve 1.2 g of titanium sulfate in a mixed solvent of 50 mL of acetonitrile / ethanol (volume ratio 1:1), and stir while adding dropwise until solution A is formed;

[0055] (4) Disperse the zinc oxide particles treated in step 2 in a mixed solvent of 300mL acetonitrile / ethanol / water (volume ratio 1:1:0), then add solution A, age the resulting precipitate for 3 hours and wash , centrifuging, and drying to obtain core-shell type zinc oxide / titanium oxide composite particles;

[0056] (5) Uniformly disperse the core-shell type zinc oxide / titanium oxide composite particles obtained in step 4 in hydraulic oil (mass fraction: 60%) to obtain core-shell t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap