Hidden type structure for electric connecting terminal of electric heating floor

An electric heating floor and electrical connection technology, which is applied in the field of hidden structures, can solve the problems of foam crushing, increased transportation costs, expenses, etc., and achieves the effect of reducing space, reducing packaging and transportation costs, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

[0019] The concealed structure of the electric connection terminal of the electric heating floor of the present invention is suitable for various types of electric heating floors.

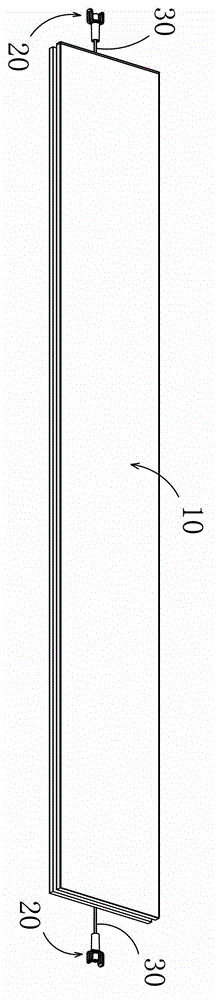

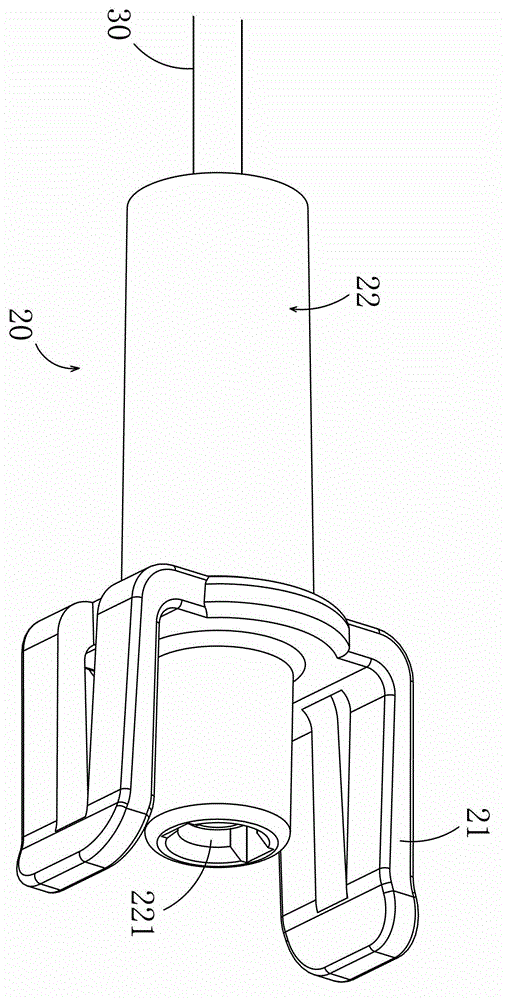

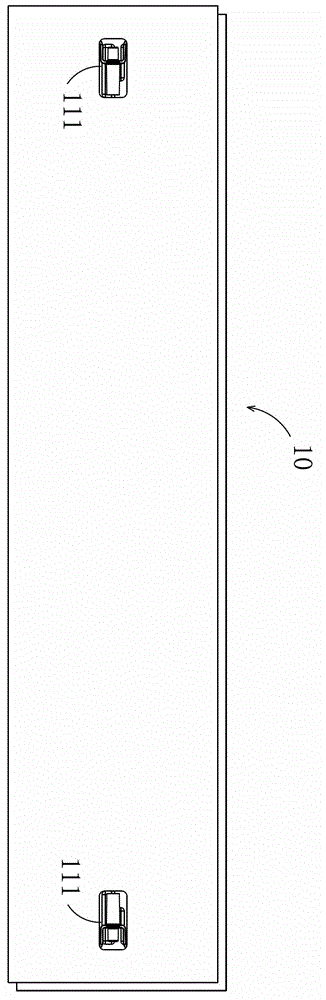

[0020] The concealed structure of the electric connection terminal of the electric heating floor of the present invention includes the electric heating floor 10, the electric connection terminal 20 and the wire 30.

[0021] Such as Figure 5 , Image 6 As shown, the electric heating floor 10 is formed by bonding a rectangular substrate 11 and a decorative board 12 with flame-retardant glue. In this example, the decorative board 12 is a solid wood sheet with a decorative function, and the lower side is provided with There are grooves for laying electric heating wires. An electric heating device such as an electric heating wire or an electric heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com