Automatic pearl taking machine for pearl mussels

A pearl oyster and machine technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of occupying human resources and low efficiency of artificially opening oysters to extract pearls, so as to save human resources, improve efficiency, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

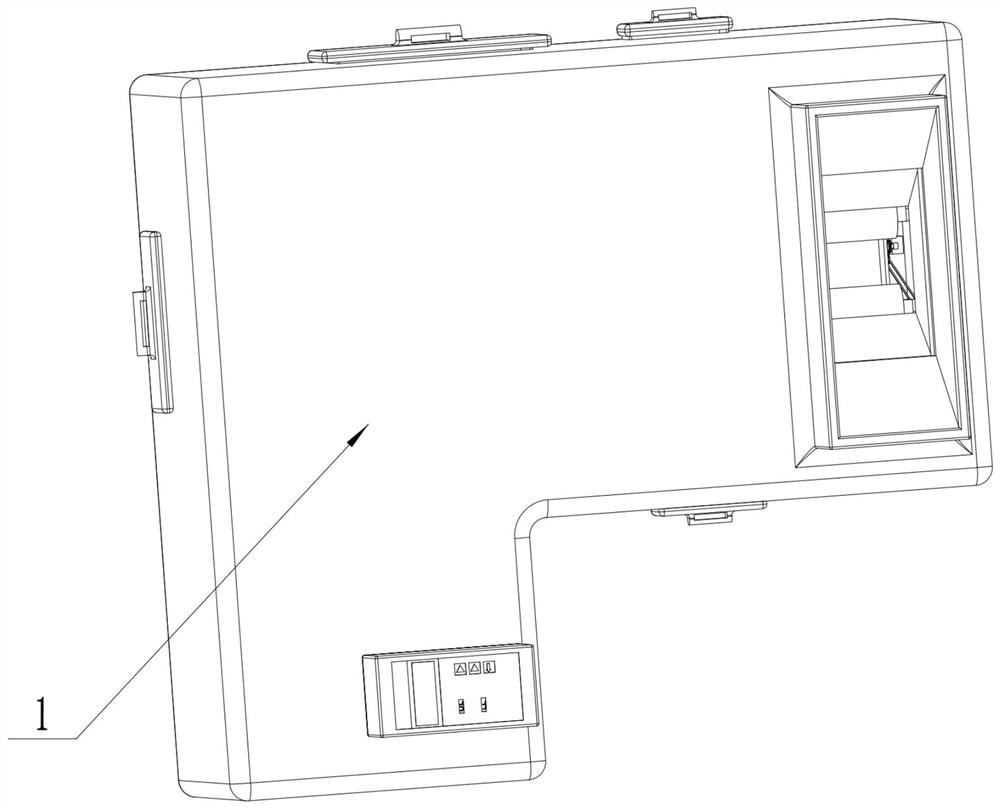

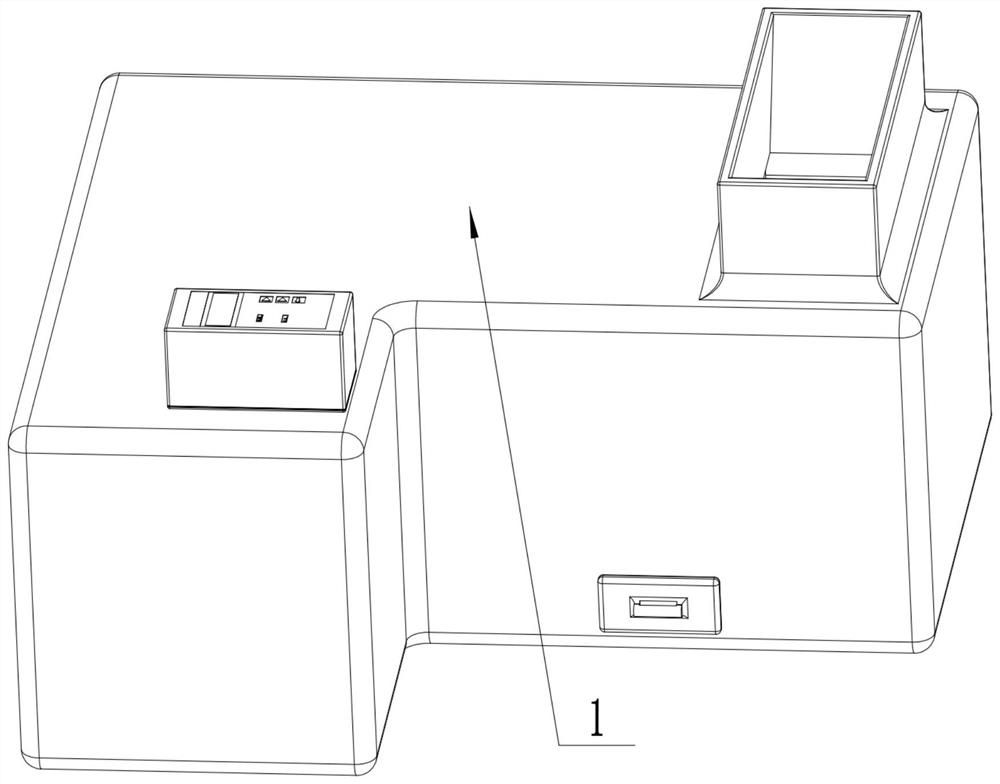

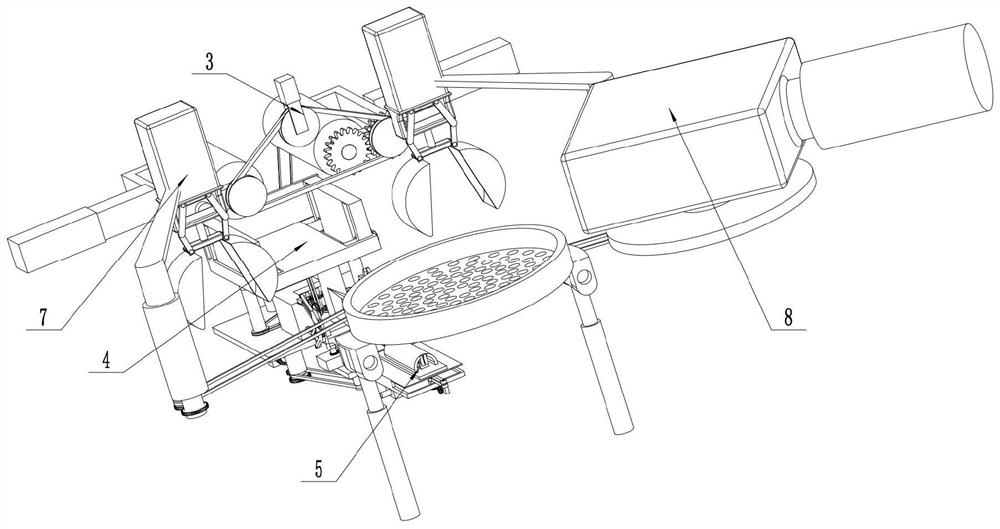

[0026]SeeFigure 1-23An automatic pear beading machine, including: outer casing portion 1, transmission portion 2, pearl odding part 3, fixed lifting portion 4, blade opening section 5, clam clamp portion 6, 蚌 meat separation rotation Part 7, the pearl take-out portion 8; the outer casing portion 1 is placed in the ground; the transmission portion 2 is mounted inside the outer casing portion 1, and the transmission portion 2 provides power for the pearl odd restricted portion 3 and the fixed lifting portion 4; pearl odding part 3 The mounting in the outer casing portion 1, the pearl odding part 3 achieves the function of the pearl, only one function, the fixed lifting portion 4 is installed inside the outer casing portion 1, the fixed lifting portion 4 realizes the pearl 蚌Function to fix and move; the blade opening section 5 is mounted inside the outer casing portion 1, and the blade opening pad portion 5 realizes the function of cutting the pearl 蚌 to cut two halves; the shell clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com