Building displacement turning method

A technology for building and rear displacement, which is applied in the direction of building construction, construction, building maintenance, etc. It can solve the problems that affect the displacement, the bottom of the underpinning beam is uneven, cracking, etc., so as to avoid additional internal force and facilitate the displacement. Bit, the effect of high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1-Figure 4 Shown, a kind of building displacement steering method, the steps are as follows:

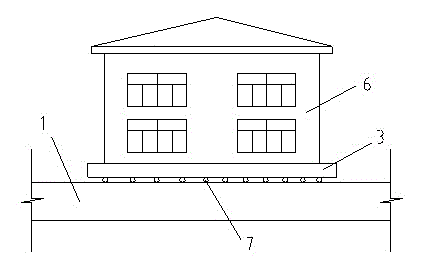

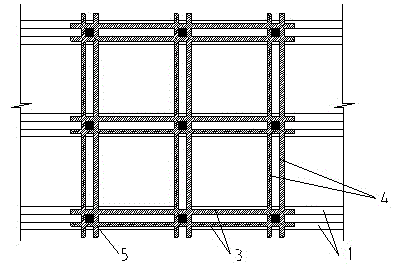

[0023] 1) For the building 6 that needs to be turned, only the roller 7 under the underpinning beam before turning is laid before shifting, and the shifting track 1 before turning, the shifting track 2 after turning and the underpinning beam 3 before turning are poured;

[0024] 2) Cut off the column or wall 5 from the foundation, and move to the turning position by traction or pushing equipment;

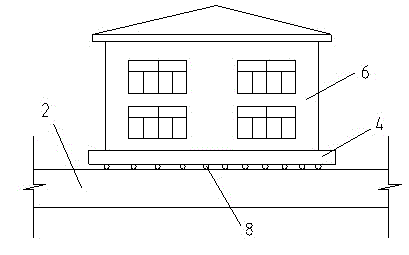

[0025] 3) Lay the roller shaft 8 under the steering rear underpinning beam on the shifting track 2 after steering, and support the channel steel on the roller shaft 8 under the steering rear underpinning beam as the bottom template pouring to make the steering rear underpinning beam 4;

[0026] 4) Cut the channel steel near the roller 7 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com