A method of realizing building shifting and turning by using track height difference

A building and track technology, applied in building construction, construction, building maintenance, etc., can solve problems such as increased construction costs, longer maintenance time, cracking, etc., to save construction time and avoid additional internal forces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

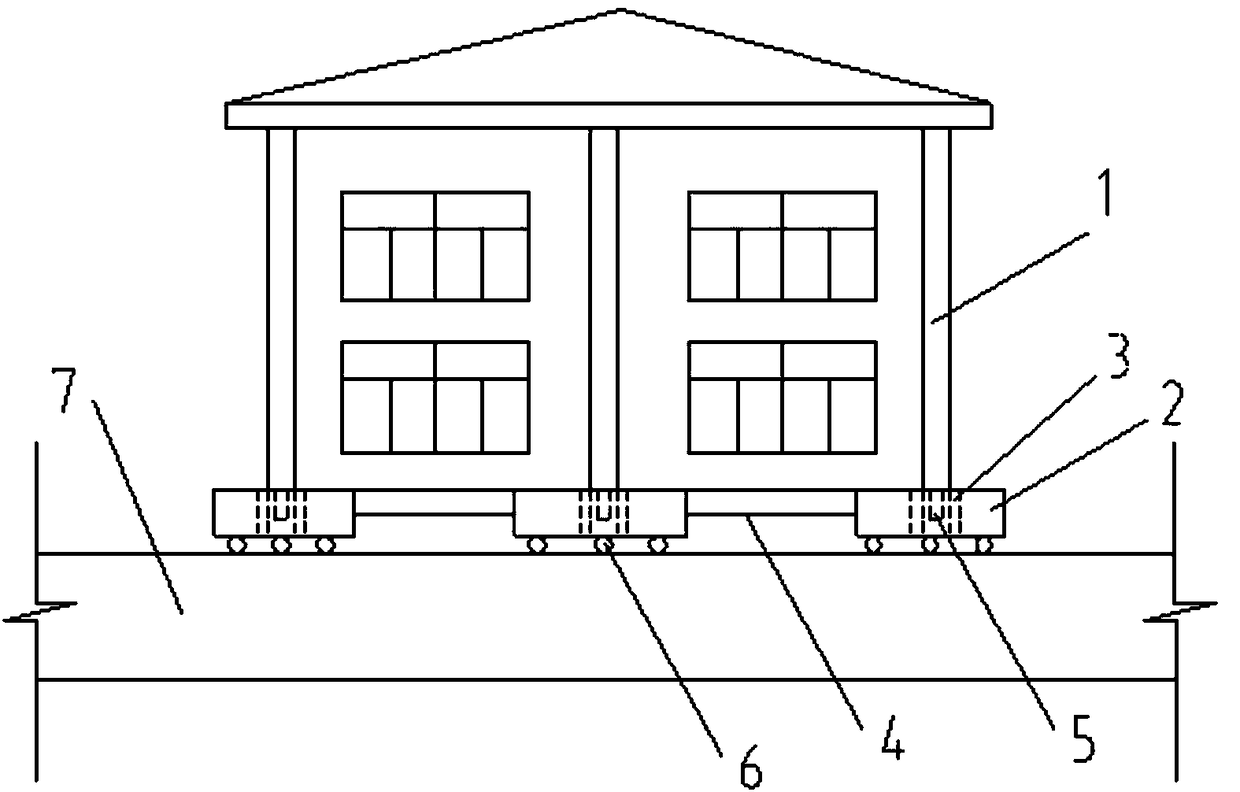

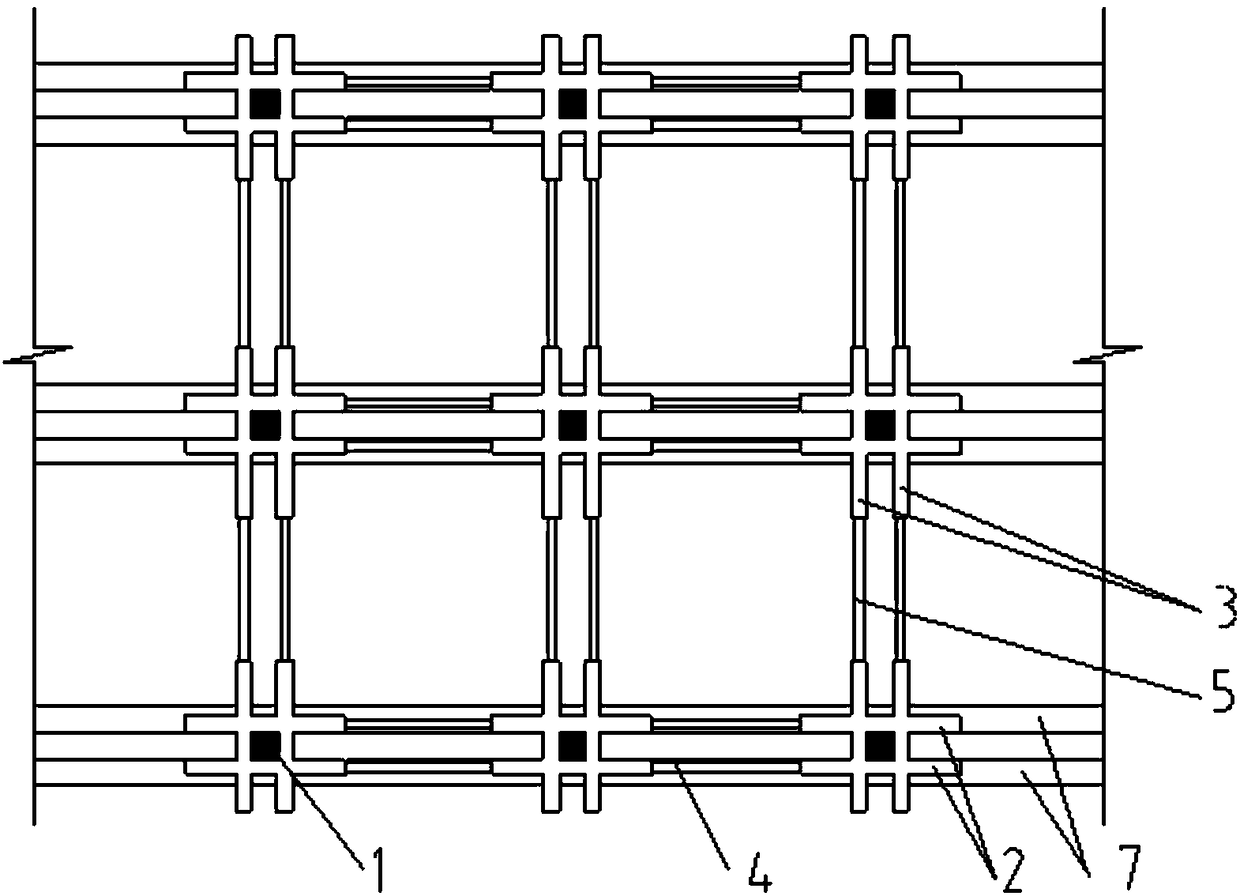

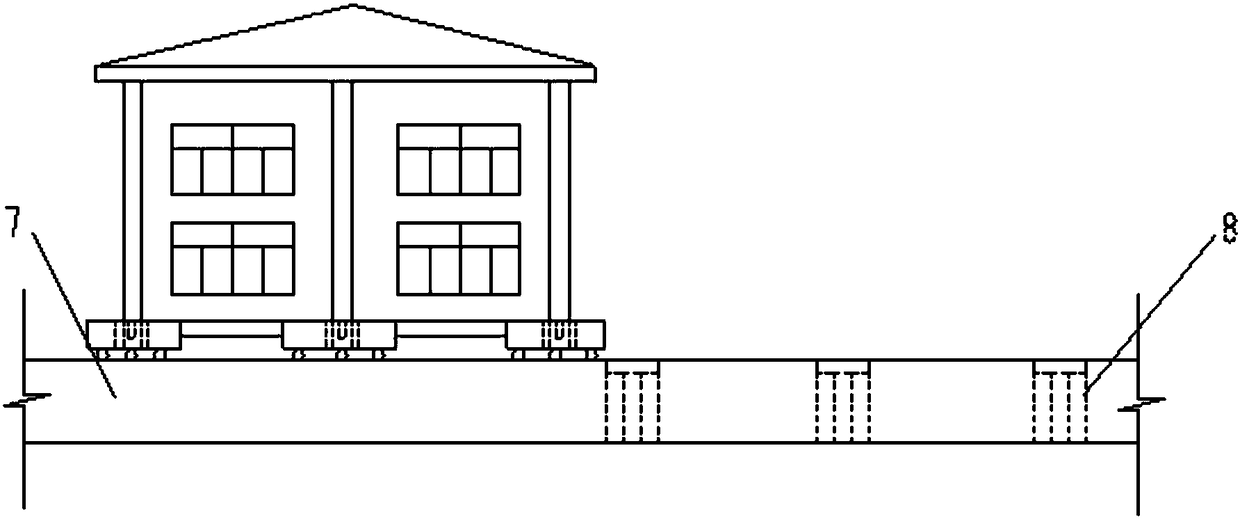

[0036] Attached below Figure 1-6 The present invention is further described:

[0037] Such as Figure 1-6 As shown, before the building is shifted and turned to in the present invention, it is necessary to pour the shifting track 7 before turning and the shifting track 8 after turning on the building shifting path, and the shifting track 7 before turning and the shifting track after turning 8 are perpendicular to each other, and the displacement track after turning is lower than the displacement track before turning; if the original elevation is required to remain unchanged after the building is shifted, the middle section of the track after turning should be made with a certain slope, and the height of the slope top is the same as the turning The elevation of the front track is the same. At the same time, multiple pre-steering concrete underpinning beams 2 and post-steering concrete underpinning beams 3 need to be poured in advance around building columns or building walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com