A bridge anti-overturning support and its construction method

A construction method and anti-overturning technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as weak anti-overturning ability, and achieve the effects of convenient material selection, overturn prevention, and avoidance of additional internal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, structure of the present invention, construction process are further described as follows.

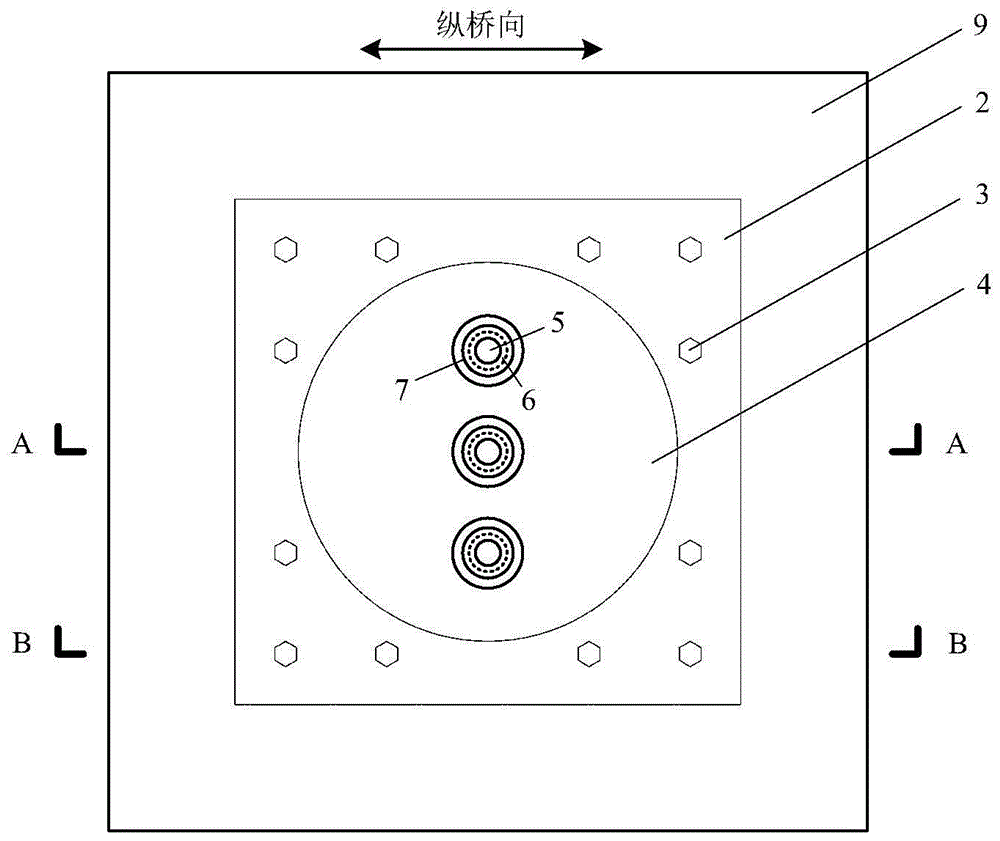

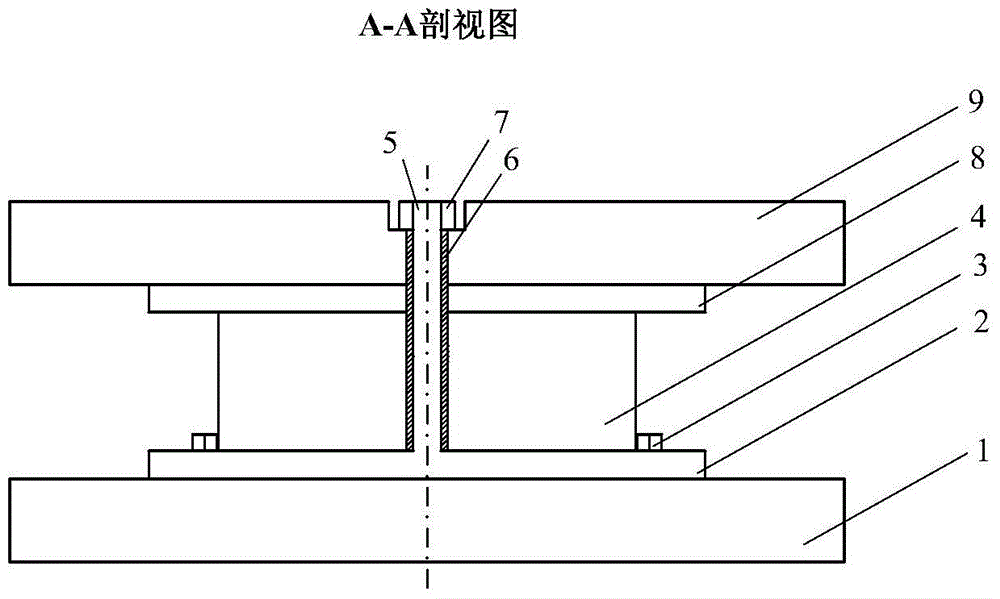

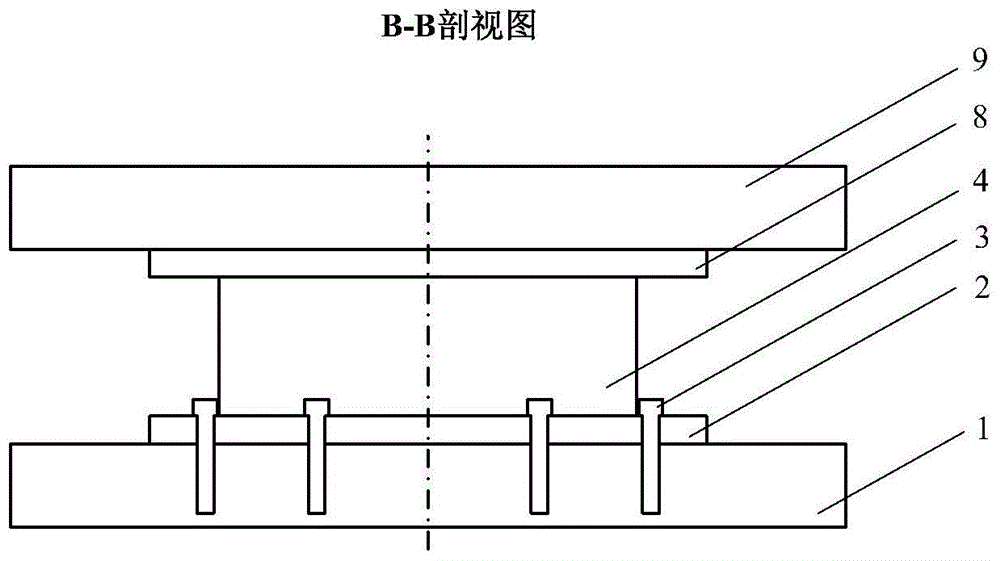

[0021] figure 1 It is a plan view of the anti-overturning support, where the dotted line represents the lower structure covered by the upper beam body 3 . A-A profile such as figure 2 As shown, the anti-overturning support is composed of a steel plate 2 under the support, a fixing bolt 3, a rubber support 4, a screw rod 5, an elastic material tube 6, a nut 7 and a steel plate 8 on the support. The screw rod 5 is welded on the steel plate 2 under the support, surrounded by an elastic material tube 6, which can be a plastic tube or a rubber tube, and the outer diameter of the nut 7 is larger than the diameter of the hole reserved in the upper beam body 9 to ensure that the nut can Together with the screw rod 5, the vertical displacement of the upper beam body 9 is restrained. B-B profile such as image 3 As shown, it shows the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com