Mechanical adjusting type centering wheel device for stepping type heating furnace bottom

A centering wheel and step-by-step technology, which is applied in the field of mechanically adjustable centering wheel devices for the step-by-step heating furnace bottom, can solve the difficult and troublesome adjustment of the centering wheel support, the deterioration of the force condition of the moving frame, and the need for centering. Deterioration of the guiding effect, etc., to ensure the centering and guiding effect, prevent additional internal force, and prevent deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

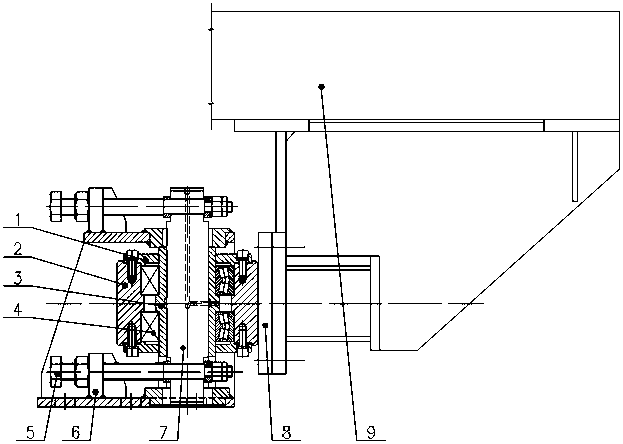

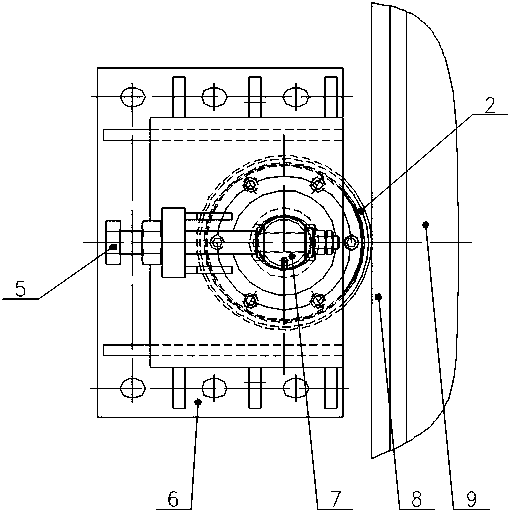

[0022] Such as figure 1 figure 2 The shown step-by-step heating furnace bottom mechanically adjustable centering wheel device includes a centering wheel support 6 and a centering wheel set installed in the wheel groove of the centering wheel support 6, wherein the centering wheel The wheel set includes a centering wheel 2 and a centering wheel shaft 7 passing through the centering wheel 2. A self-aligning roller bearing 4 and a centering wheel sleeve 3 are installed between the centering wheel shaft 7 and the centering wheel 2, and the shaft sleeve A bearing gland 1 is installed on the end face, and both sides of the wheel groove of the centering wheel support 6 are provided with elongated shaft holes for the centering wheel shaft 7 to pass through, and the centering wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com