Backlight module and liquid crystal display device

A technology for a liquid crystal display device and a backlight module, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problem of light leakage on the light-incident side of the light guide plate 40, easy to turn outwards, and increase the manufacturing cost of liquid crystal display devices. and operating energy consumption, to achieve the effect of reducing manufacturing cost and operating power consumption, improving optical coupling efficiency, and improving optical coupling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

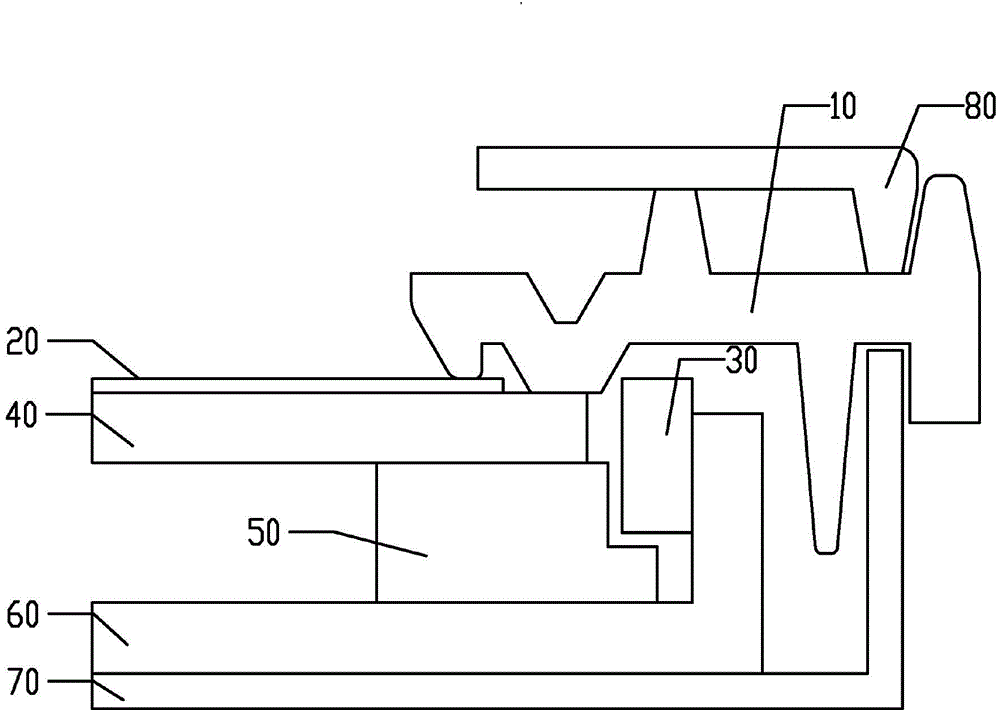

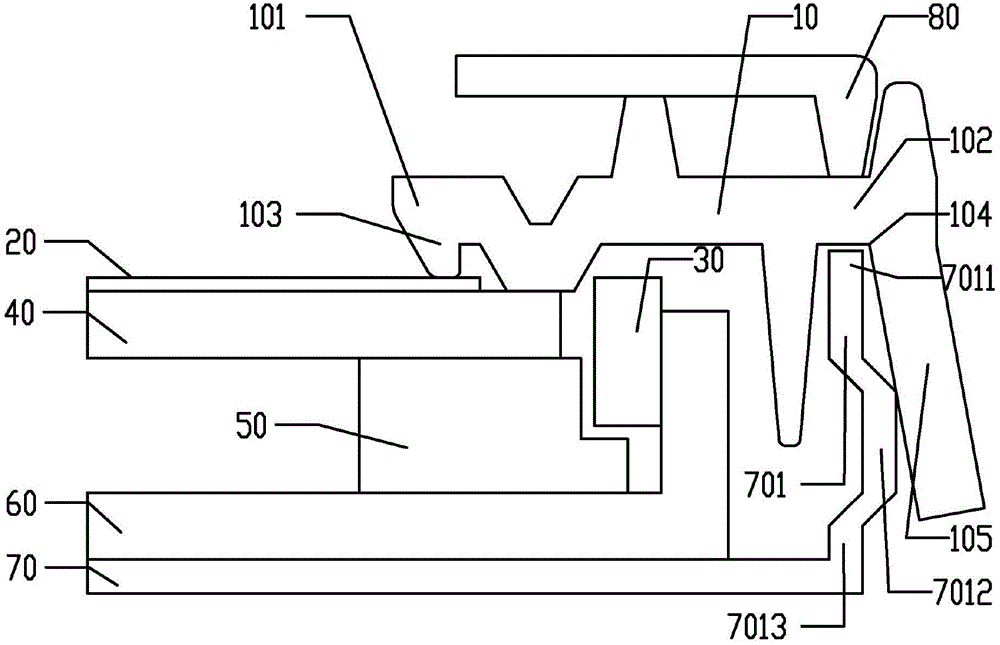

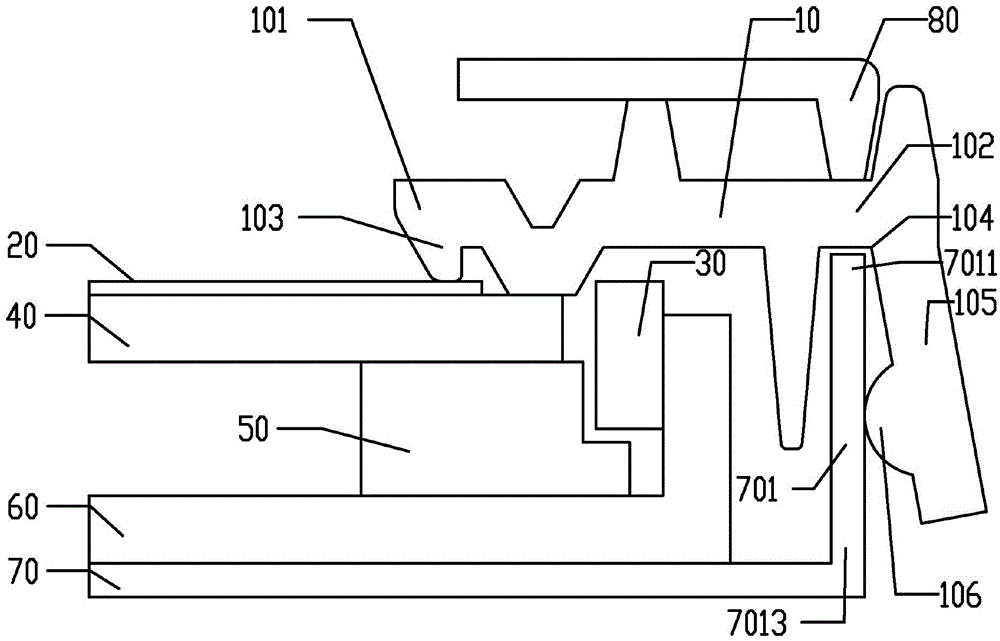

[0026] refer to figure 2 , figure 2 It is a partial schematic diagram of the first embodiment of the backlight module of the present invention. In this embodiment, the backlight module of the present invention includes a backplane 70 , a heat sink 60 , a support member 50 , a light guide plate 40 , a light source 30 , an optical film 20 , a plastic frame 10 and a frame 80 . The edge of the back plate 70 has a side wall 701, the light guide plate 40 is placed on the back plate 70, the light source 30 is placed on the side of the light guide plate 40, the optical film 20 is placed on the light guide plate 40, and the plastic frame 10 is placed on the The optical film 20 and the sidewall 701 of the backplane 70 . The plastic frame 10 has a first end 101 and a second end 102, the first end 101 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com