Method for driving infrared multi-point touch screen

A technology of multi-touch screen and driving method, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. The effect of response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

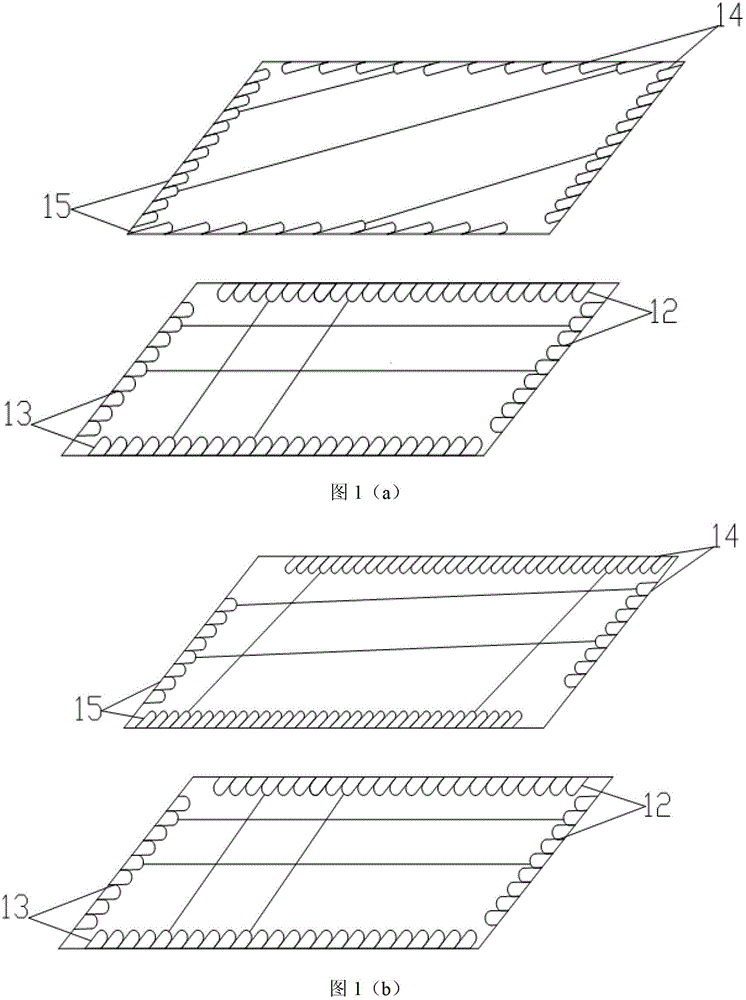

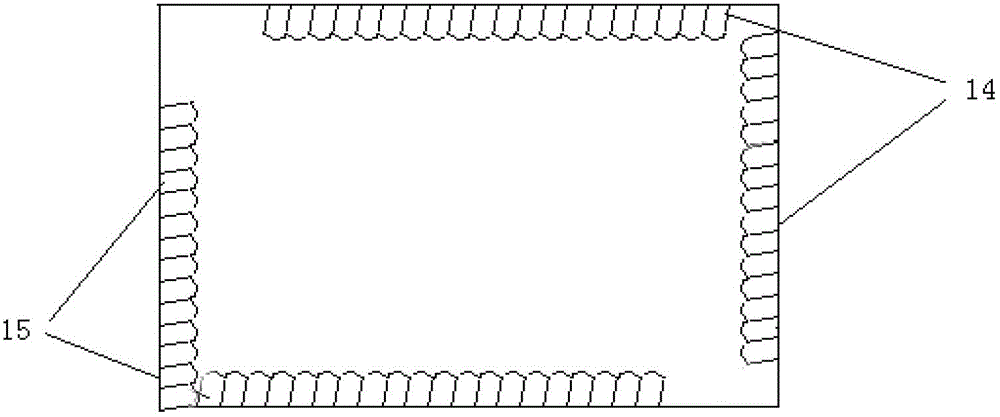

[0017] Such as figure 1 shown. The surroundings of the upper touch panel and the lower touch panel are respectively covered with infrared tubes, wherein the adjacent two edges of the lower touch panel are covered with infrared emitting tubes 12, and the remaining two adjacent edges are covered with infrared receiving tubes 13. The outgoing light of the infrared emitting tubes 12 is directed to the opposite infrared receiving tubes 13 in one-to-one correspondence, forming a vertically orthogonal pair of infrared tubes. Infrared emitting tubes 14 inclined at a certain angle are placed on two adjacent edges of the upper touch panel, and infrared receiving tubes 15 inclined at a certain angle are placed on the other two adjacent edges. figure 1 (a), (b) two structures, where figure 1 In (a), the outgoing light of each infrared emitting tube on the upper touch panel corresponds to the infrared receiving tube on the adjacent edge along the oblique direction, forming an obliquely i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com