Fuel injection valve and internal combustion engine

A technology of fuel injection valve and internal combustion engine, which is applied in the directions of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve the problems of bubble breakage, uneven bubble diameter, and it is difficult to obtain uniform spray, and achieves uniform bubble diameter, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

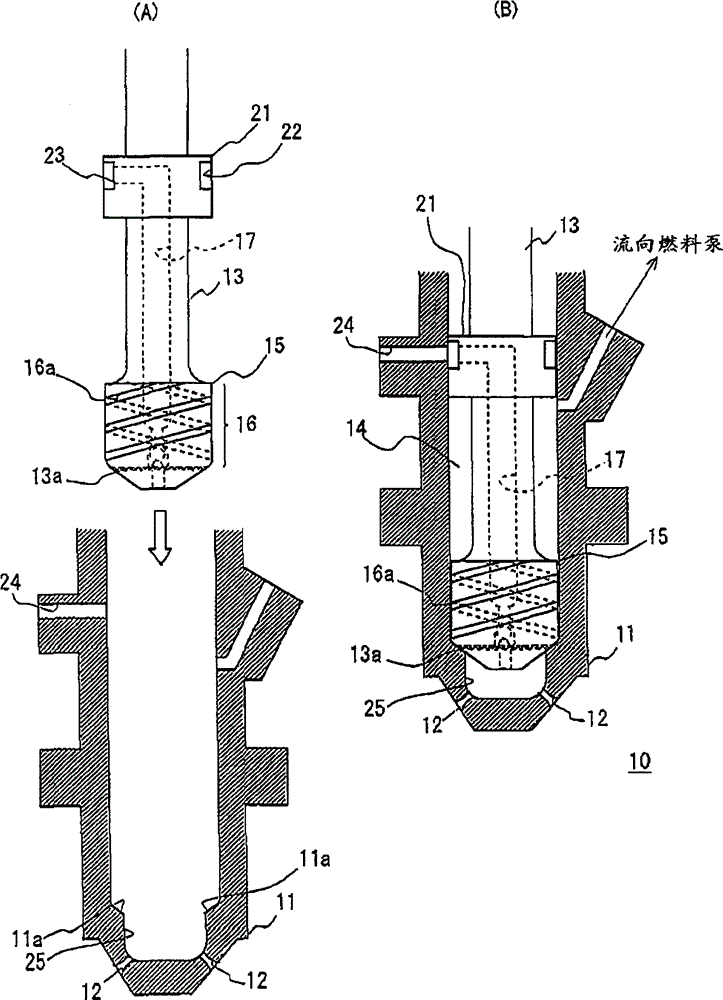

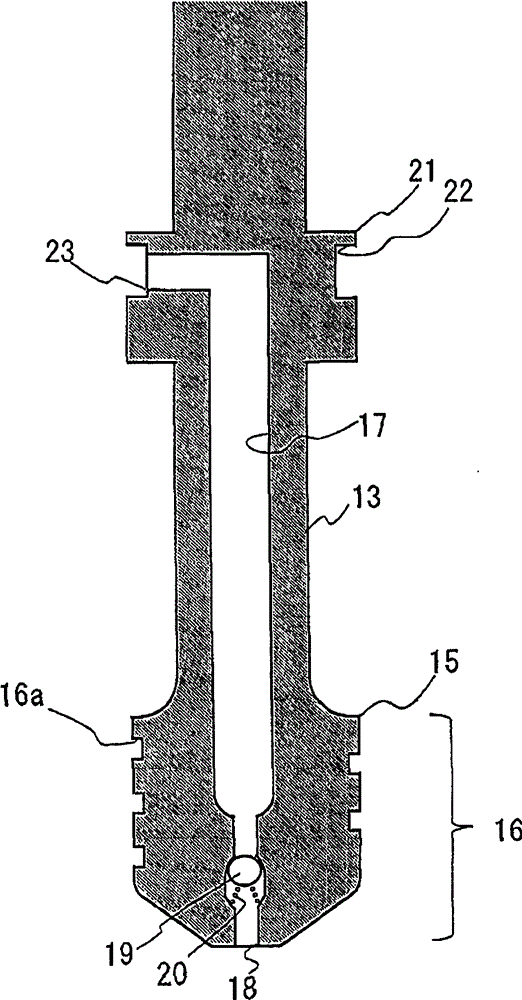

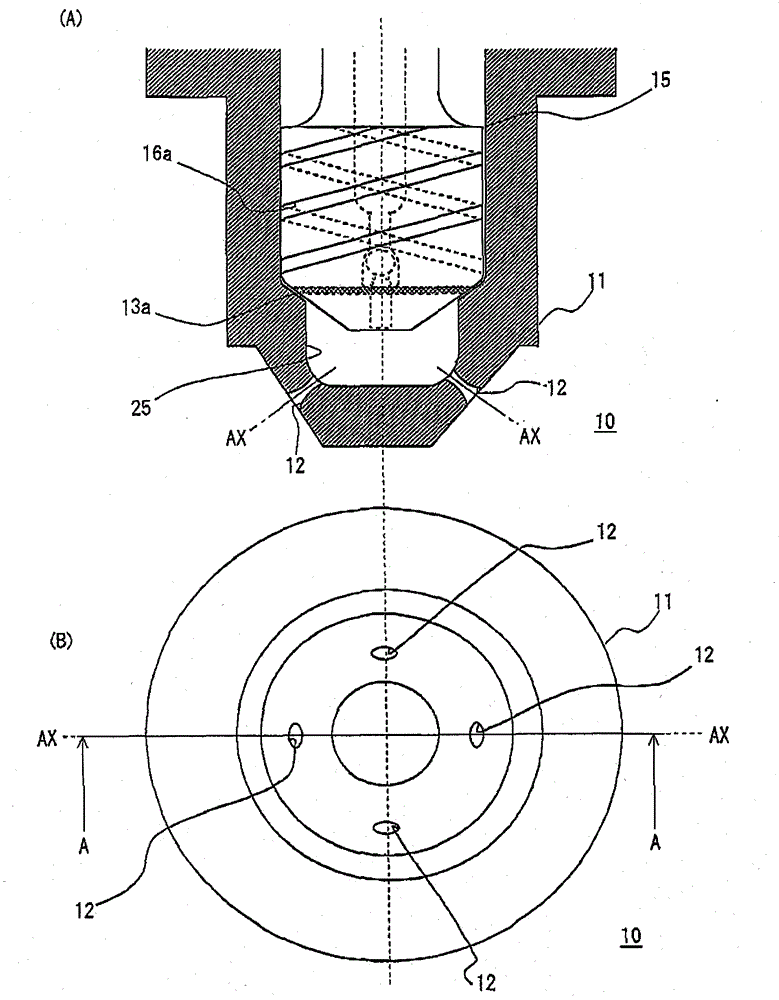

[0037] refer to figure 1 (A)~ Figure 5 (B) Embodiment 1 of the fuel injection valve disclosed in this specification will be described. figure 1 (A) is an explanatory diagram showing a state where the nozzle body 11 and the needle 13 of the fuel injection valve 10 are separated. figure 1 (B) is an explanatory diagram showing a state where the needle 13 is combined with the nozzle body 11 of the fuel injection valve 10 . figure 2 It is a sectional view of the needle 13 included in the fuel injection valve 10 . image 3 (A) is image 3 Line A-A of (B) is a cross-sectional view of the front end of the fuel injection valve as a cross-section, image 3 (B) is a front view of the fuel injection valve of the first embodiment.

[0038] The fuel injection valve 10 is mounted on an internal combustion engine, such as a gasoline engine, but the internal combustion engine is not limited to a gasoline engine, and may be any of a diesel engine using light oil as fuel, or a flexible fu...

Embodiment 2

[0063] Next, refer to Figure 6-8 Example 2 will be described. Image 6 (A) is Image 6 The B-B line of (B) is a sectional view in which the front end portion of the fuel injection valve 30 is formed as a cross section, Image 6 (B) is a front view of the fuel injection valve 30 . Figure 7 It is an explanatory diagram schematically showing the internal combustion engine 150 equipped with the fuel injection valve 30 . in addition, Figure 8 It is an explanatory diagram showing the relationship between the nozzle hole length, the spray angle, and the area ratio.

[0064] The internal combustion engine 150 includes an engine main body 151 having a combustion chamber 152 . In combustion chamber 152 , fuel injection valve 30 is mounted such that its tip is exposed in combustion chamber 152 . Fuel injection valve 30 is arranged in the center of combustion chamber 152 . In addition, the piston 153 is attached to the engine main body 151 . Furthermore, a spark plug 154 is att...

Embodiment 3

[0071] Then refer to Figure 9 , Figure 10 Example 3 will be described. Figure 9 (A) is Figure 9 The line C-C of (B) is a cross-sectional view of the front end portion of the fuel injection valve 70 . Figure 9 (B) is a front view of the fuel injection valve 70 . Figure 10 It is an explanatory diagram schematically showing an internal combustion engine 200 equipped with a fuel injection valve 70 .

[0072] The internal combustion engine 200 includes an engine main body 201 having a combustion chamber 202 . In combustion chamber 202 , fuel injection valve 70 is mounted such that its tip is exposed in combustion chamber 202 . Fuel injection valve 70 is arranged on the side of combustion chamber 202 . In addition, the piston 203 is attached to the engine main body 201 . Furthermore, a spark plug 204 is mounted so that the tip is exposed at the center of the combustion chamber 202 .

[0073] In this way, when the fuel injection valve 70 and the spark plug 204 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com