Axial-flow type isodirectional outflow cyclone separator

A flow separation and axial flow technology, which is applied in swirling devices, devices whose axial direction of swirling remains unchanged, etc., can solve the problem of poor removal of small oil droplets, low oil removal efficiency in the settling section, and difficulty in meeting water injection requirements. and other problems to achieve the effect of enhancing the stability of the flow field, reducing the turbulence and stabilizing the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

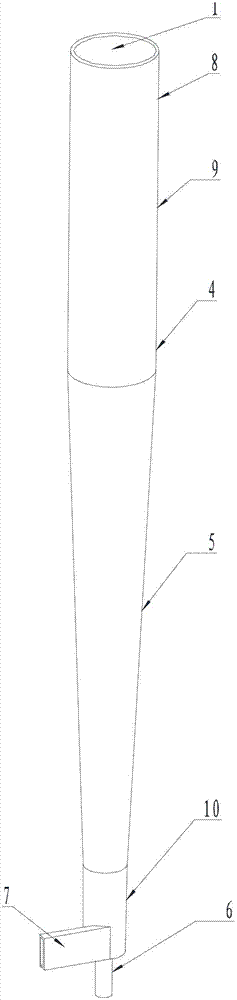

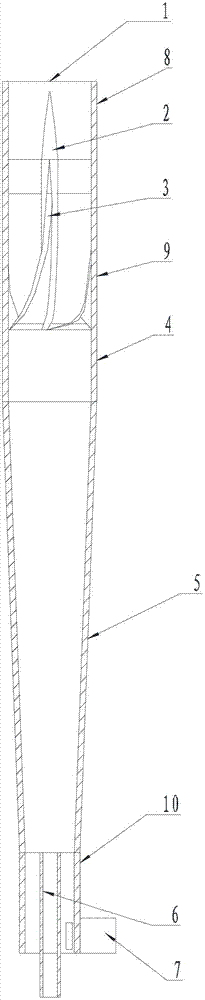

[0020] Depend on figure 1 combine figure 2 , image 3 As shown in the figure, this kind of axial flow co-current outflow cyclone separator includes an inlet chamber 8, a steady flow guide chamber 9, a cyclone chamber 4, a positive cone chamber 5 and a separation chamber 10, which are connected in sequence. Axisymmetric structure.

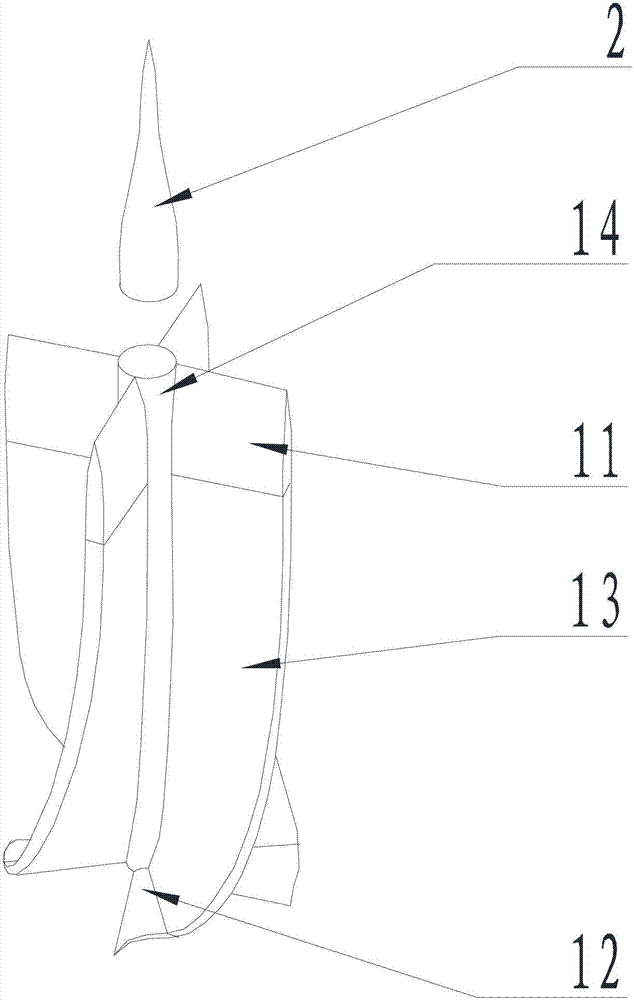

[0021] Wherein, there is a guide body 3 in the steady flow guide cavity 9 , and the guide body 3 is formed by connecting at least three guide vanes 13 and the central shaft 14 . The structure of the conducting fluid is image 3 As shown in the figure, there are 4 blades, in practical application, there can be more. The guide vane 13 is of a variable helix angle structure; the upper end of the guide body 3 is fixed at the junction of the inlet chamber 8 and the steady flow guide chamber 9 , and the upper end of the guide body 3 is fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap