Car pulling platform for locomotive works

A technology for tractors and locomotive factories, applied in turntables/moving platforms, railway car body components, transportation and packaging, etc. It can solve problems such as large floor area, many tracks, and inconvenient daily maintenance of tractors , to achieve the effect of convenient rail change, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

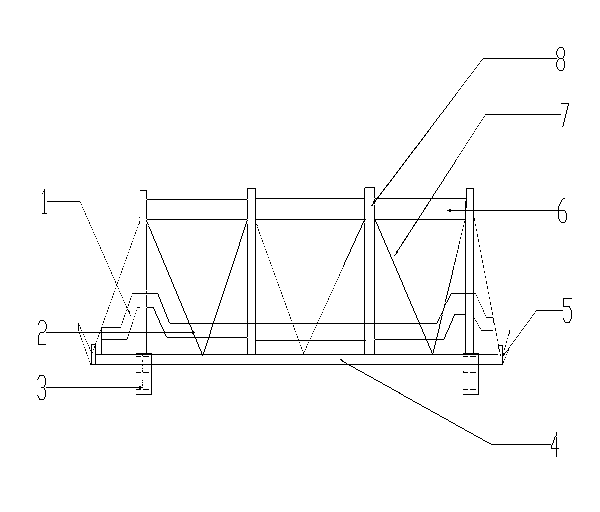

[0013] A traction platform for a locomotive factory, comprising a vehicle frame 1, a traveling frame structure 2, a plurality of rail wheels 3, a chassis 4, and a rail changing device 5, and the traveling frame structure 2 further includes: a beam 6, a hanging beam 7, and a hanging column 8. The track wheels 8 are installed on the chassis 4; the chassis 4 is installed on the frame 1, and the feature is that: a row frame structure 2 is installed on the frame 1, and a rail changing device is installed at both ends of the frame 1 5.

[0014] A crossbeam 6 is installed in parallel on the upper end of the chassis 4, and a plurality of suspenders 8 are installed equidistantly between the crossbeam 6 and the chassis 4; , the other end is connected to the suspension column 8; the suspension beam 7 and the chassis 4 form a number of isosceles triangle structures, such a structure transfers part of the gravity to the traveling frame structure 2, and shares the load of the chassis 4.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com