Comprehensive sensitivity analyzing method for rigidity of automobile body

A sensitivity analysis, automobile body technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve problems such as ineffectiveness and unscientific calculation results, and achieve the effect of avoiding correlation problems between parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

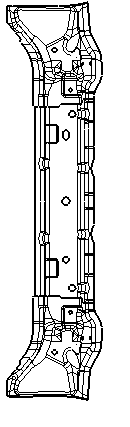

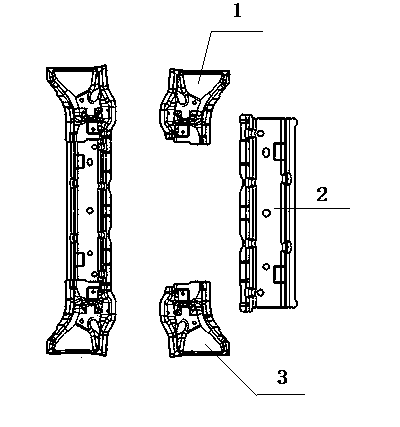

[0018] Combine below figure 1 with figure 2 , the present invention is further described:

[0019] Based on the automobile body, the present invention proposes a method for analyzing the bending stiffness, torsional stiffness, and modal characteristics of the automobile body with respect to the variation sensitivity of parameters such as the geometric dimensions of the body parts and material thickness from a systematic point of view.

[0020] Taking the rear floor beam of a certain car as an example, the traditional sensitivity calculation method is to calculate the influence rate of the parameter changes of the first part 1, the second part 2, and the third part 3 on the body stiffness and modal respectively, but due to the three The components are overlapped with each other and have a strong correlation, so the method of simply studying the influence of a certain component on the stiffness mode of the vehicle body has relatively large defects.

[0021] In order to solve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com