Folded paddle type ship propeller

A propeller and marine technology, which is applied in the field of folding fin marine propellers, can solve the problems of low work efficiency, high operating intensity, exhaust gas and noise pollution, etc., and achieve the effect of low noise and good concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

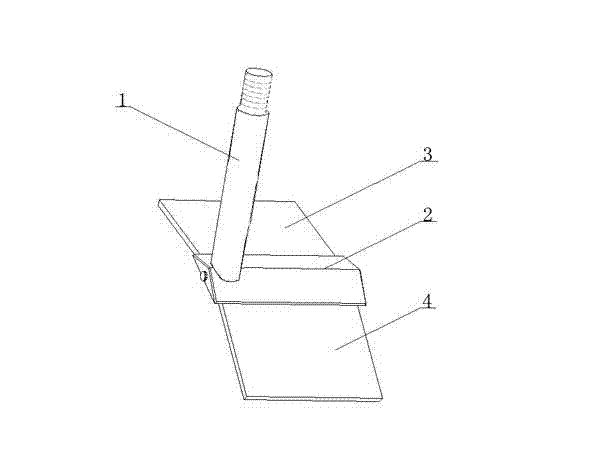

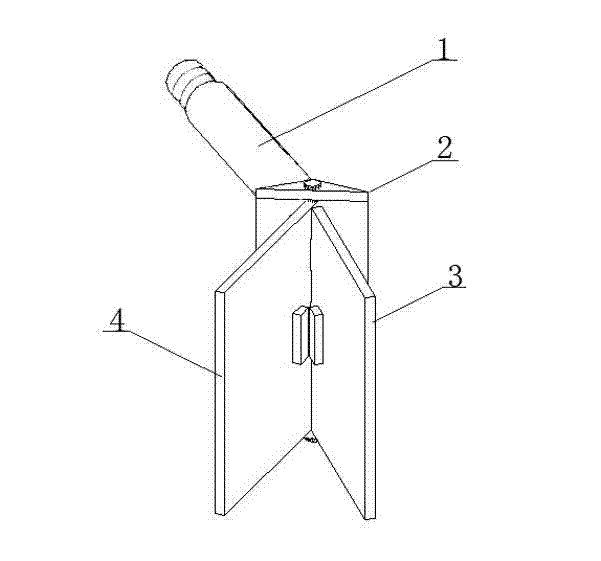

[0015] As shown in the figure: a folding webbed marine propeller, mainly composed of connecting arm 1, water diversion bracket 2, web plate I3 and web plate II4, wherein one end of the connecting arm 1 is provided with a connecting thread, and the other end of the connecting arm 1 is provided with a connecting thread. One end is connected to the water distribution bracket 2.

[0016] The water diversion bracket 2 is a V-shaped groove structure composed of two water diversion plates 5 and two side plates 6, wherein the angle between the two water diversion plates 5 is 140-160°, and the two side plates 6 is correspondingly provided with the rotating shaft through hole 7.

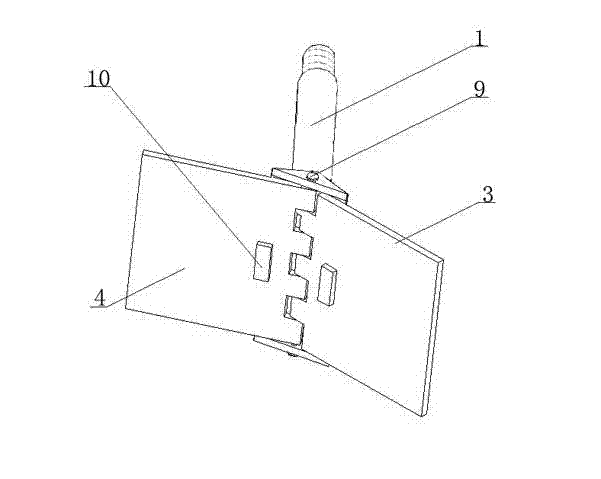

[0017] The fins Ⅰ3 and Ⅱ4 are hinged together through the rotating shaft 8, which is similar to the traditional hinge structure. Both the webs Ⅰ3 and Ⅱ4 can rotate along the rotating shaft 8, and the side of the webs Ⅰ3 and Ⅱ4 are mutually matched. The concave-convex groove structure of the web plate I3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com