Washing machine

A washing machine and water tank technology, applied in the field of washing machines, can solve the problem of difficulty in detecting whether the water tank 82 is fixed and maintained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

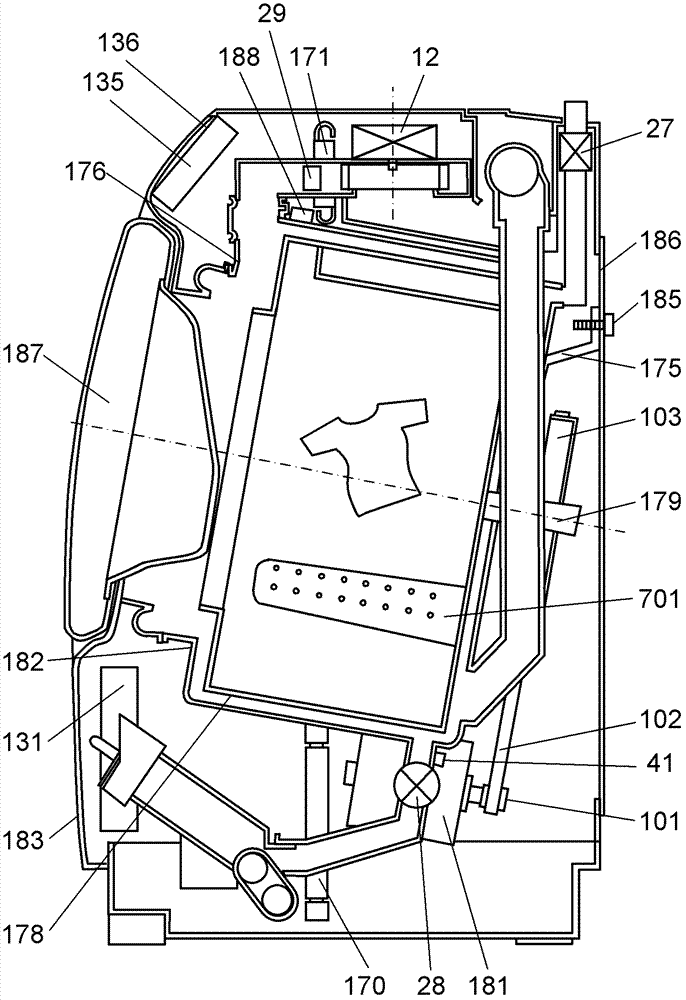

[0036] figure 1 It is a sectional view of the washing machine according to the embodiment of the present invention.

[0037] Such as figure 1 As shown, the washing machine of this embodiment includes at least a main body 183 , a water tank 182 , a drum 178 , fixing bolts 185 , a water supply valve 27 , a motor 181 , and a control unit 131 .

[0038] The water tank 182 is provided swingably inside the main body 183, and the direction of the rotation shaft 179 is inclined downward from the horizontal direction from the front side of the opening toward the rear side serving as the bottom. A drum 178 is rotatably provided inside the water tank 182 . Further, the drum 178 is connected to a motor 181 attached to a lower portion on the back side which is the bottom of the water tank 182 via a motor pulley 101 , a belt 102 , a drive pulley 103 , and the like. Further, the drum 178 is rotationally driven by the motor 181 in the forward rotation and reverse rotation directions arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com