Pretension prestress composite beam prefabricated component having gaps and corbels

A technology of prefabricated components and composite beams, applied in the direction of long strip structural components, building components, structural elements, etc. for load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

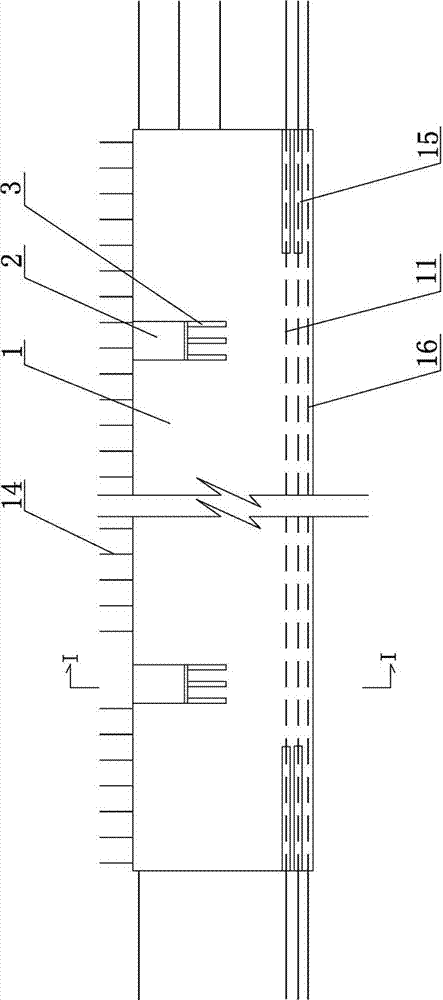

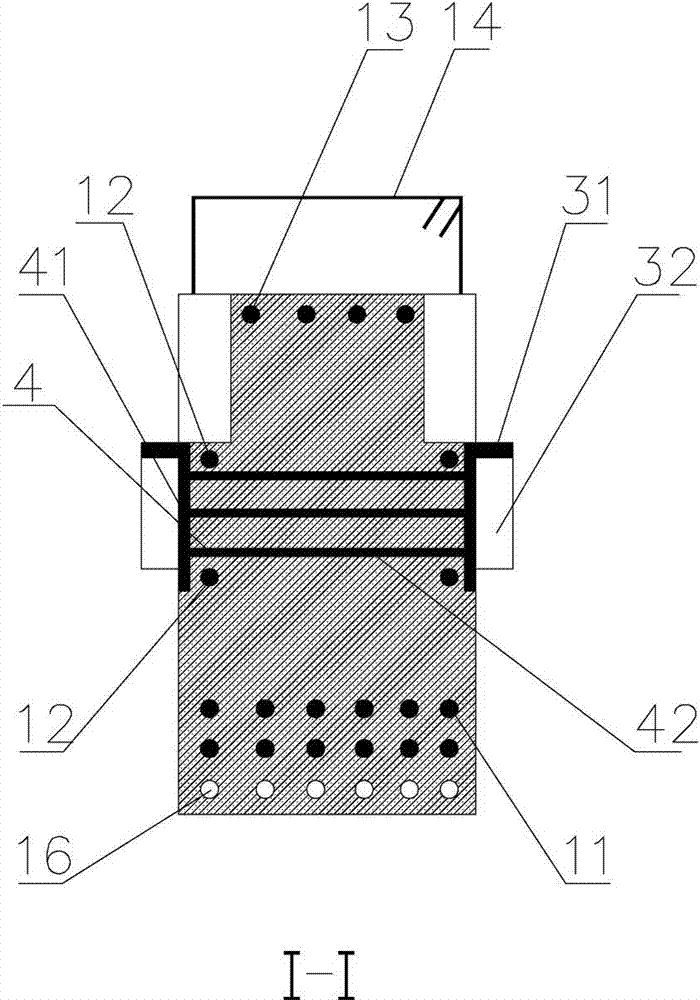

[0024] Please refer to the attached figure 1 And attached figure 2 As shown, the present invention is a pre-tensioned prestressed composite beam prefabricated component with gaps and corbels, which includes a composite beam prefabricated component main body 1; on the composite beam prefabricated component main body 1 Several notches 2 are provided; a corbel 3 is provided at the bottom of each notch 2 .

[0025] Further, the main body part 1 of the composite beam prefabricated component is provided with a lower prestressed steel bar 11 , a waist bar 12 , an upper prestressed steel bar 13 , a stirrup 14 and a corbel embedded part 4 . Wherein, the lower prestressed steel bar 11 is a high-strength steel strand, and when the multi-layer lower prestressed steel bar 11 needs to be configured according to the calculation of the limit state of the bearing capacity, a plastic pipe 15 or Wrap plastic cloth 15 to form a free contraction section, the length of the plastic tube or plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com