Novel integrated LED (light-emitting diode) headlight

A technology of light emitting diodes and headlights, applied in the field of lamps, can solve the problems of unfavorable energy saving and environmental protection light emitting diode vehicles, insufficient headlight flux, difficult change of color temperature, etc., so as to avoid glare reflection angle, improve driving safety, and improve heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technology will be further described below in conjunction with the accompanying drawings.

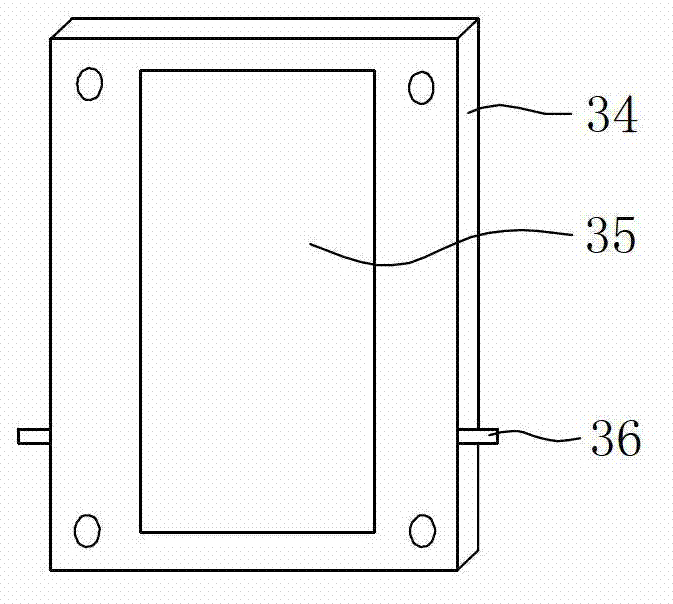

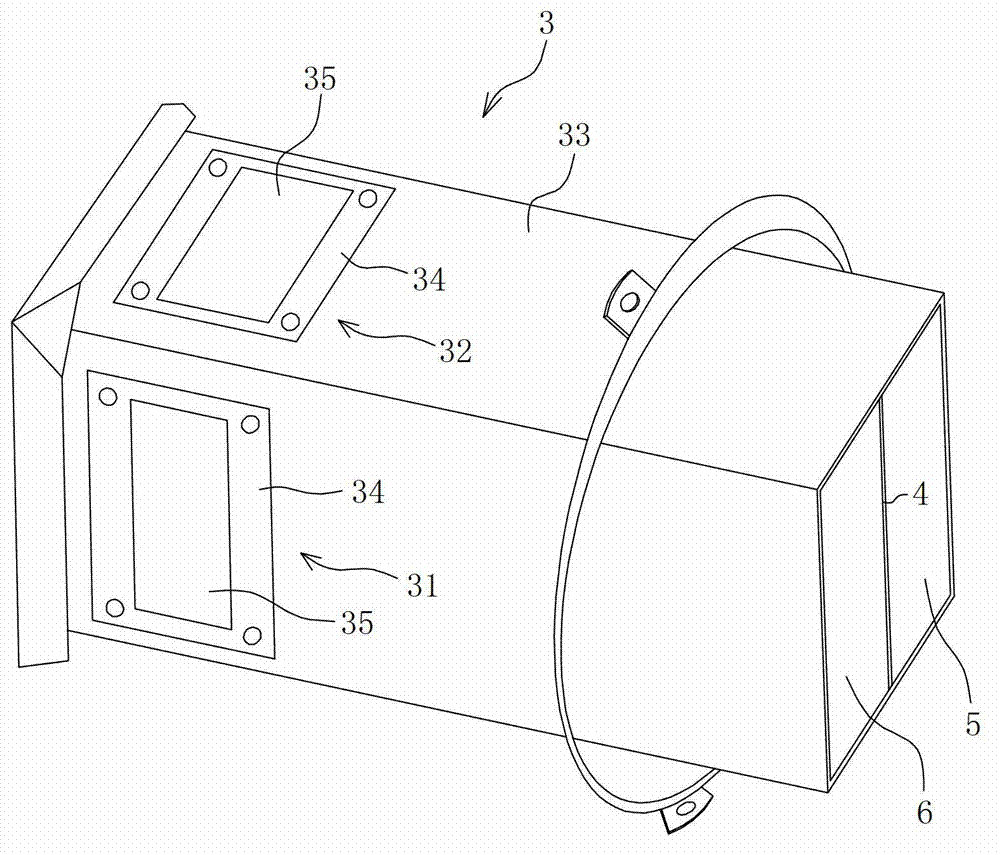

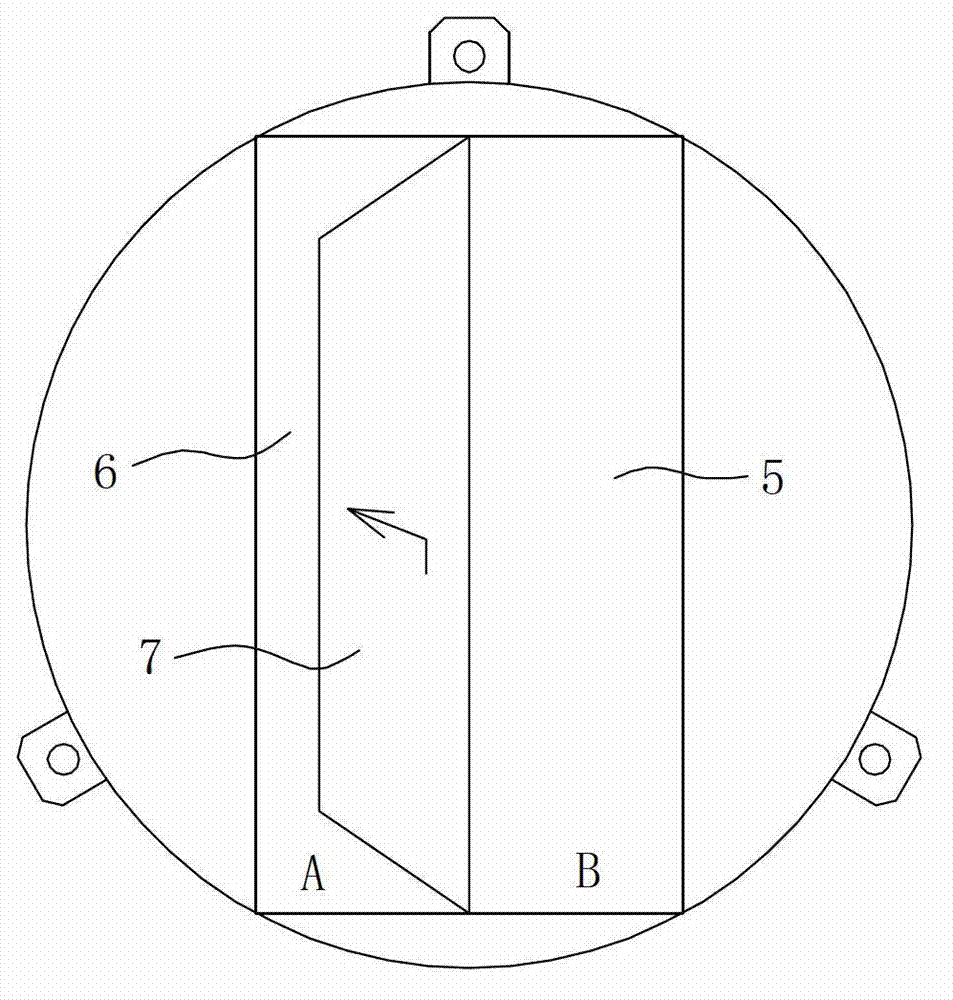

[0026] The new integrated light-emitting diode headlamp includes a light source, a reflector 1 and a transparent mask 2, the transparent mask 2 covers the outlet of the reflector 1, the light source is located in the reflector 1, the light source is an integrated light-emitting diode wick 3, and the integrated light-emitting diode The wick 3 is a hollow structure, and a partition plate 4 is provided in the inner cavity of the integrated LED wick 3, and the partition plate 4 divides the inner cavity of the integrated LED wick 3 into a high-temperature cooling chamber 5 and a low-temperature cooling chamber 6, and a high-temperature cooling chamber 5 and a low-temperature cooling chamber. The low-temperature cooling chamber 6 communicates with the end of the integrated LED wick 3 , the inner end of the partition plate 4 is provided with a deflector 7 bent toward the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com