Closed force flow type gear box abrasion oil liquid monitoring test stand

A technology of oil monitoring and gearbox, which is applied in machine gear/transmission mechanism testing, wear resistance testing, etc. It can solve the problems of inability to reverse loading, affect the accuracy of the experiment, and easy load loss, etc., and achieve the goal of reducing the loading force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

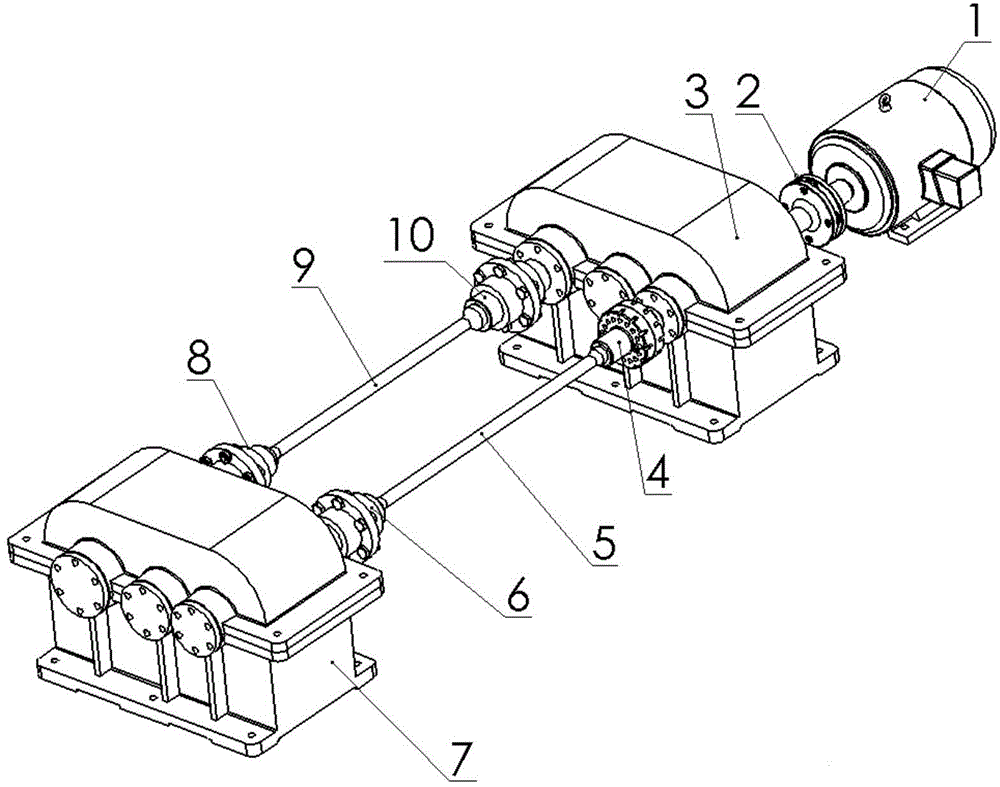

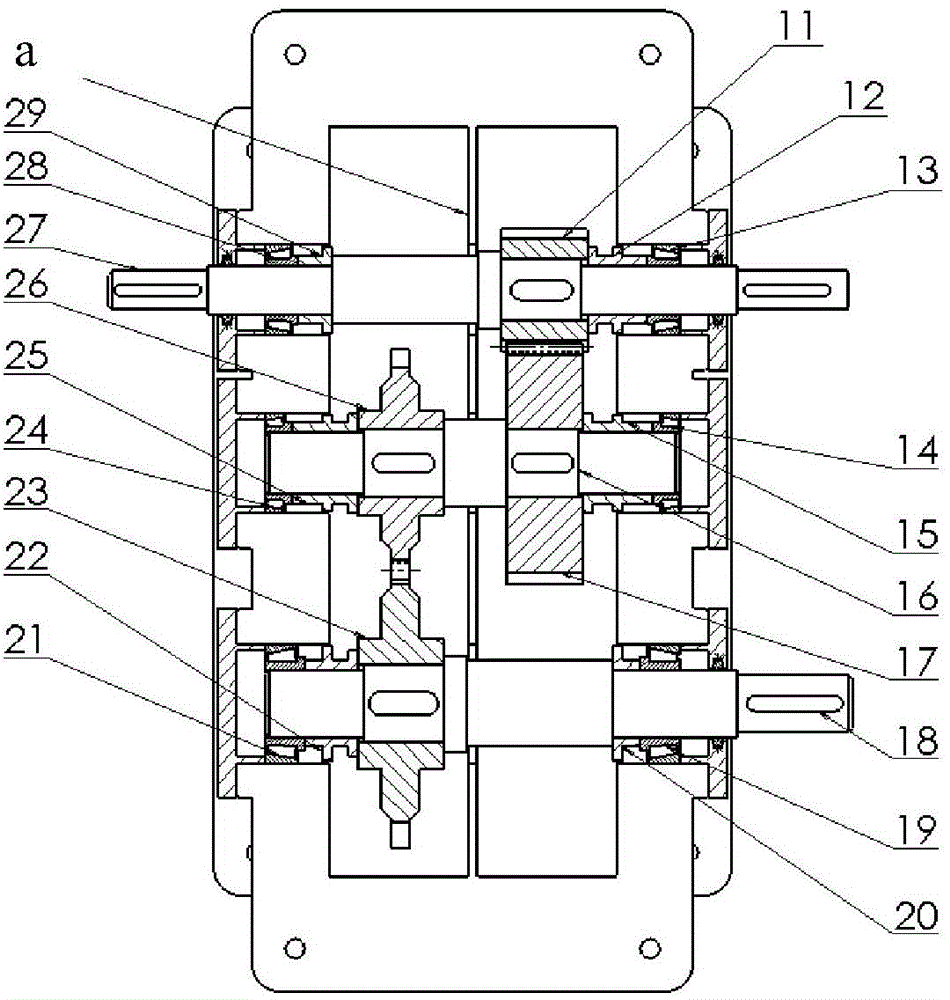

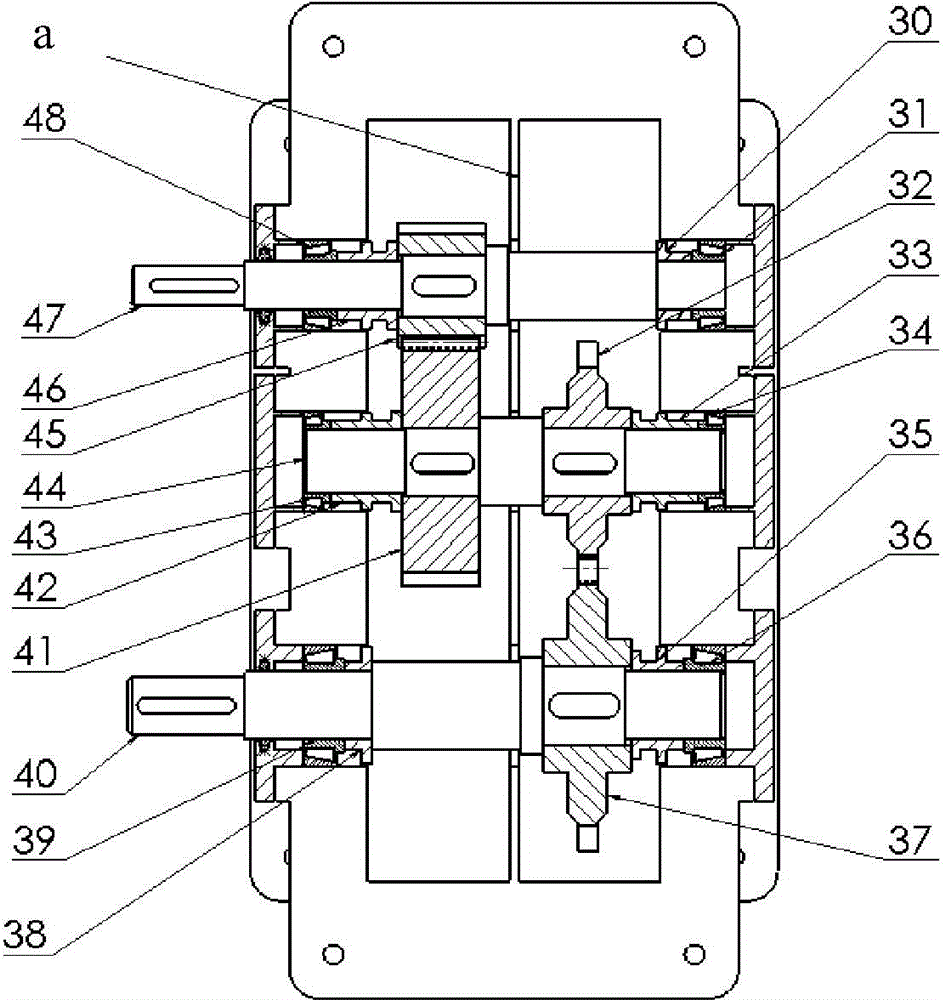

[0024] see figure 1 , the closed force flow gear wear oil monitoring test bench of the present invention includes a driving motor 1 , a first test gear box 3 connected to the drive motor 1 and a second test gear box 7 connected to the first test gear box 3 . In the first test gear box 3 is a two-stage cylindrical gear transmission composed of the first high-speed shaft 27, the first intermediate shaft 16, the first low-speed shaft 18 and the gears on each shaft; Two-stage cylindrical gear transmission formed by gears on two high-speed shafts 47, the second intermediate shaft 44, the second low-speed shaft 40 and each shaft. The first test gear box 3 and the second test gear box 7 are connected by two elastic torsion shafts.

[0025] The driving motor 1 is connected to the first high-speed shaft 27 of the first test gear box through the diaphragm coupling 2, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com