Engine timing chain tension testing device and method

A test device and engine technology, applied in the direction of engine test, measurement device, mechanical component test, etc., can solve problems such as failure to achieve actual reference value, more simplified models, and reduced accuracy, and achieve a simple and easy-to-understand test method. , The effect of low test cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with each accompanying drawing, the present invention is described in detail.

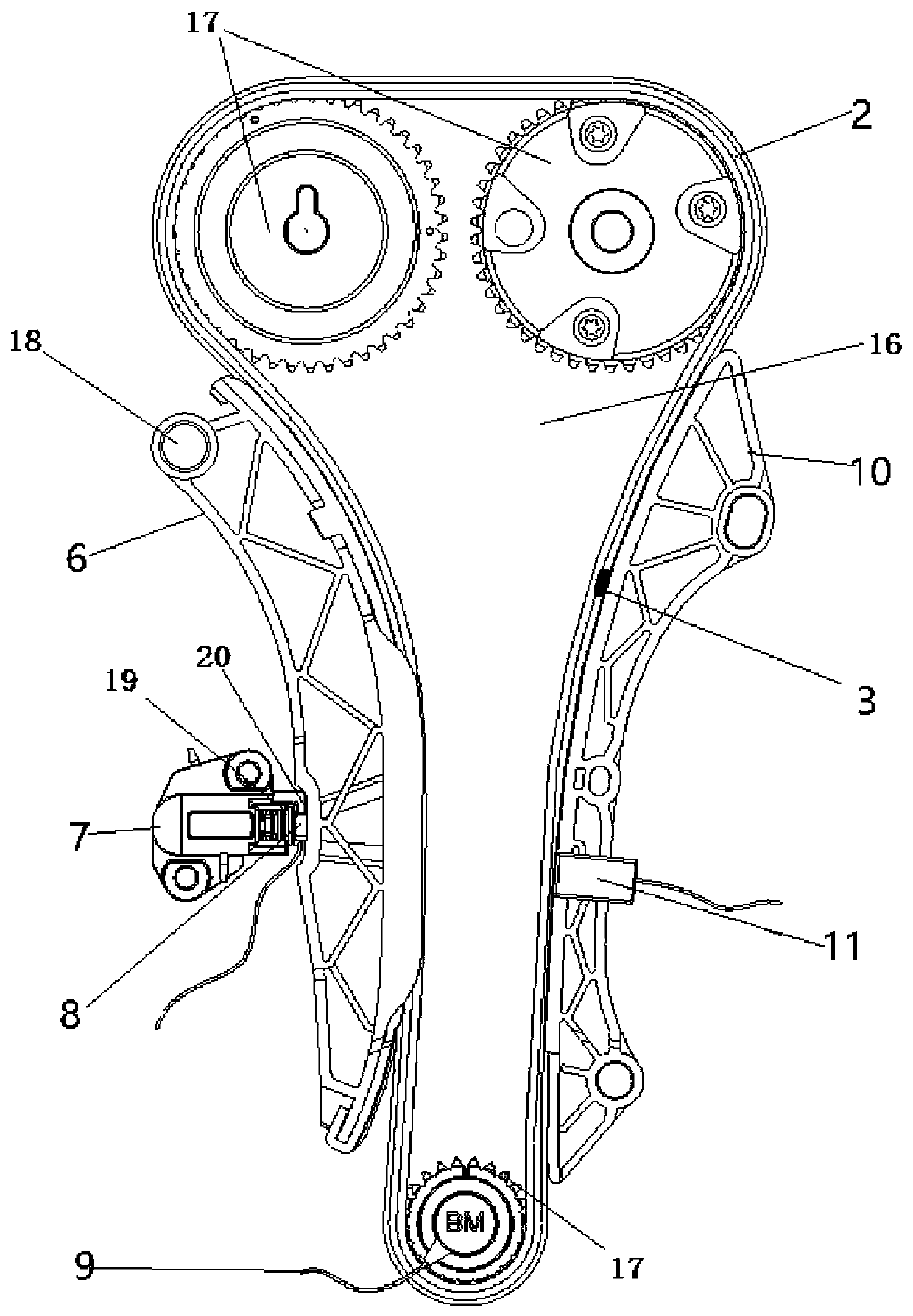

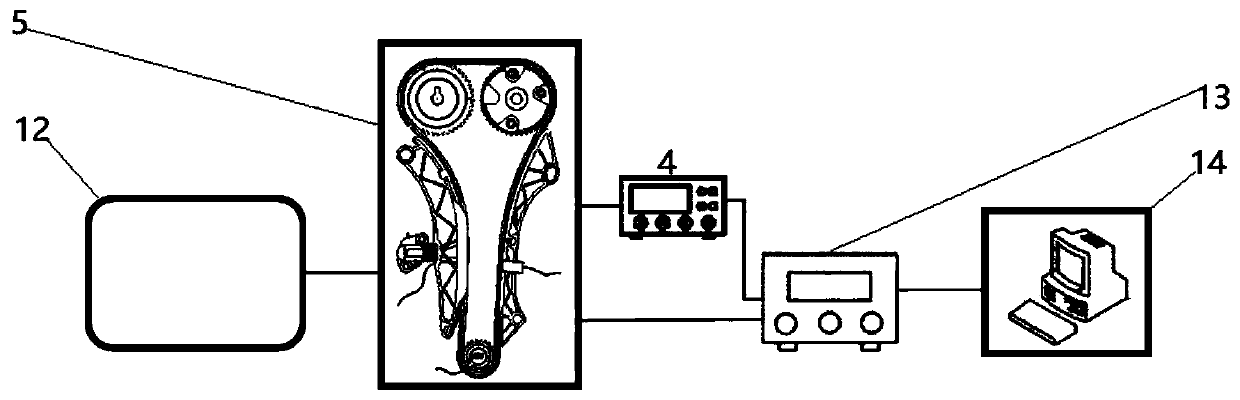

[0042] Such as figure 1 , 2 Shown in and 3, a kind of engine timing chain tension testing device comprises:

[0043] The engine 5 has a timing system, and the timing system includes a frame 16, a plurality of sprockets 17 that are rotatably mounted on the frame 16 and a timing chain 2 that is used to wind around each sprocket 17, and the timing system also It includes a fixed rail 10 fixed on the frame 16, a moving rail 6 rotatably mounted on the frame 16, and a tensioner 7 matched with the moving rail 6. The fixed rail 10 and the moving rail 6 are both arranged on the timing chain 2. The outer side is used to contact and cooperate with the timing chain 2;

[0044] The strain gauge 3 is used to be attached to the timing chain 2;

[0045] A dynamic strain gauge 4 is electrically connected to the strain gauge 3;

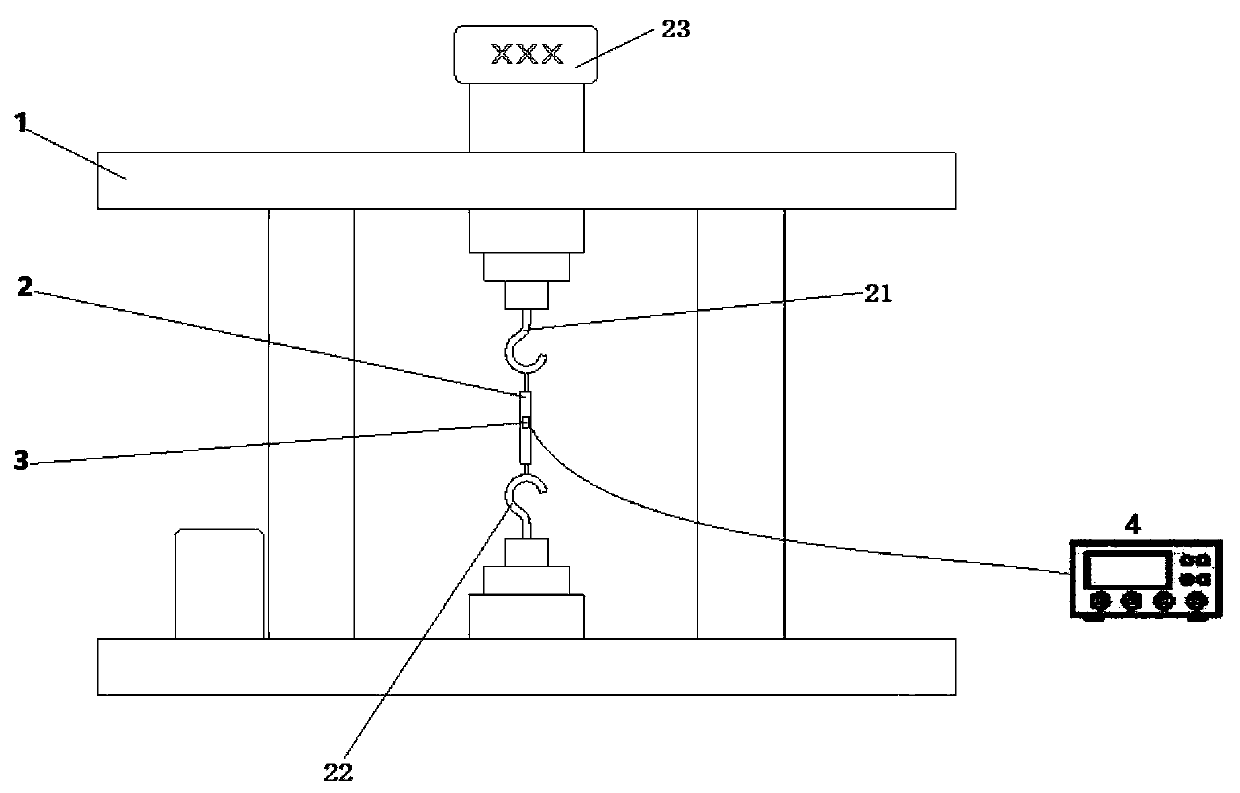

[0046] Tensile test stand 1 is used to cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com