Novel underwater pipeline mechanical connector

A technology for mechanical connectors and underwater pipes, applied in mechanical equipment, couplings, etc., can solve the problems affecting the performance of the connection, the decline of the performance of the threaded connection, and the complicated installation tools, so as to reduce the loading force, ensure the contact strength, The effect of improving the contact strength and contact static sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

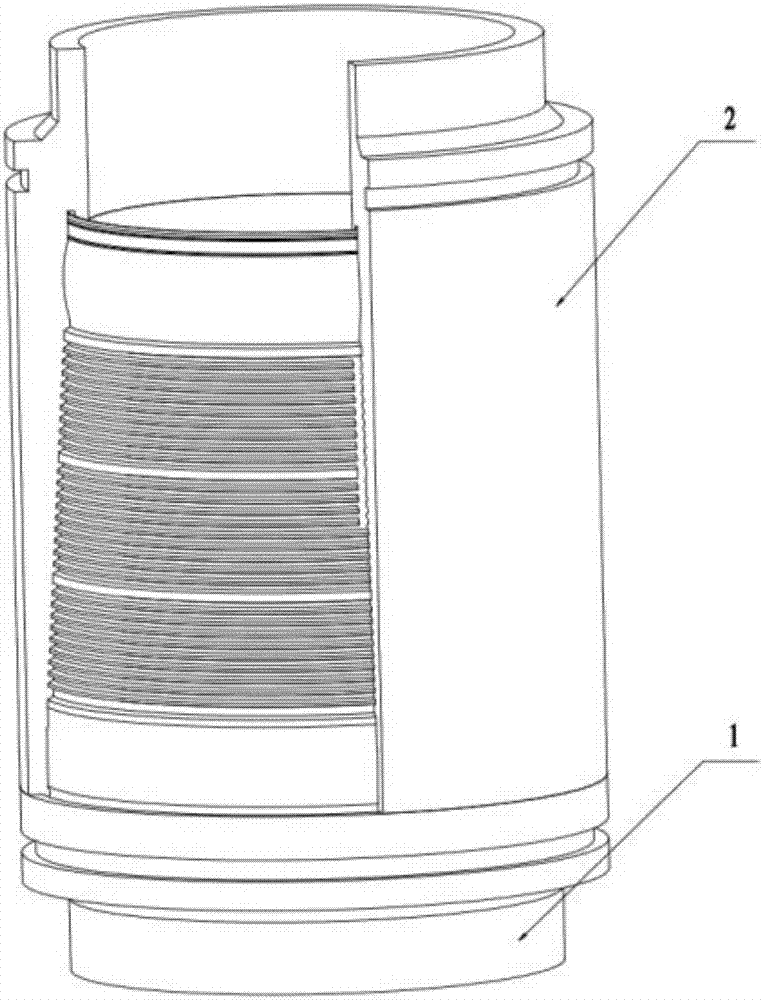

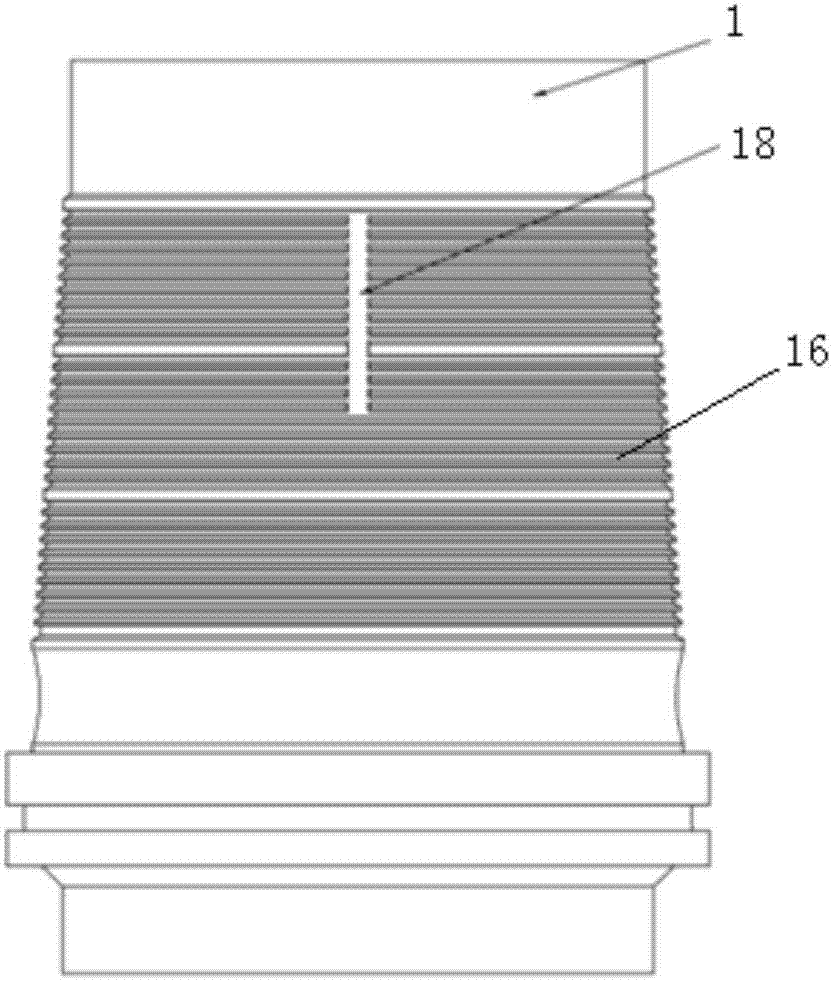

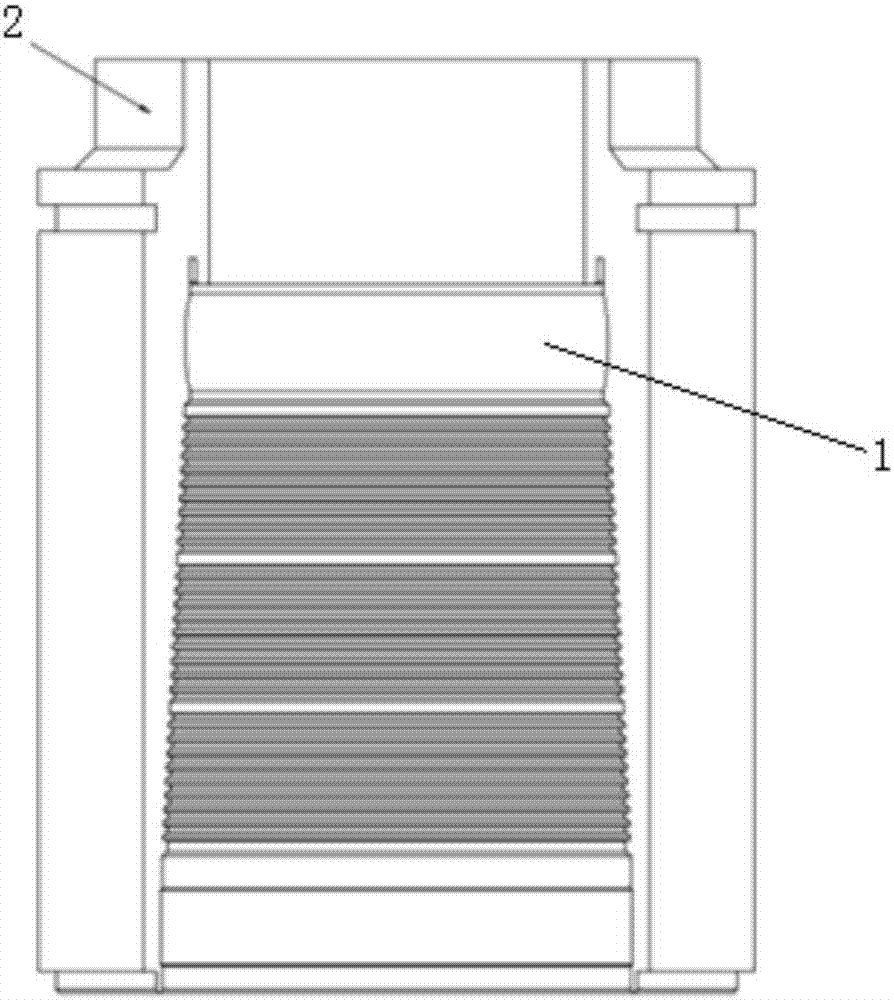

[0032] Such as Figure 1 to Figure 7 As shown, the novel underwater pipeline mechanical connector of the present invention includes a tubular pin 1 and a tubular sleeve 2 for connecting pipelines. The shape of a hollow cylinder, the tubular sleeve 2 and the tubular pin 1 are both arranged in an axisymmetric structure. Both the tubular sleeve 2 and the tubular pin 1 are made of steel, preferably high-strength steel.

[0033] The outer surface of the tubular pin 1 is sequentially arranged as an upper cylindrical surface 14, an outer tooth segment 16, a lower unloading groove 11 and a lower positioning installation groove 4 from top to bottom, and the top of the upper cylindrical surface 14 is provided with a ring-shaped upper Flange 12, between the lower unloading groove 11 and the lower positioning installation groove 4 is provided with an axial lower connection groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com