Fluid filter and method of using same

A fluid filter and filter element technology, applied in the direction of membrane filters, cartridge filters, chemical instruments and methods, etc., can solve the problems of oil spillage, difficulty in ensuring the sealing of the discharge passage for a long time, complicated insertion operations, etc. Achieves the effects of suppressing wear, reliable locking, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

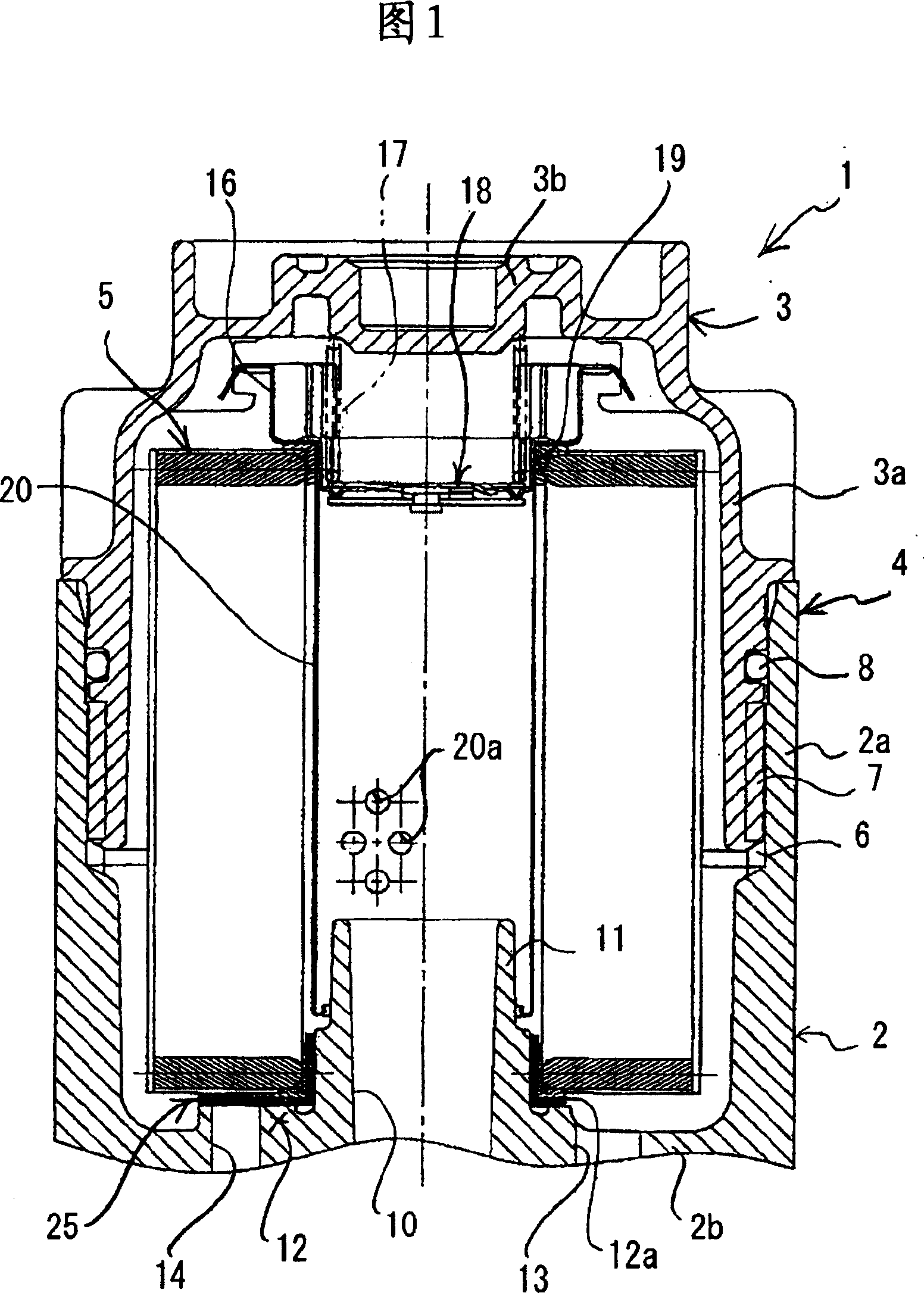

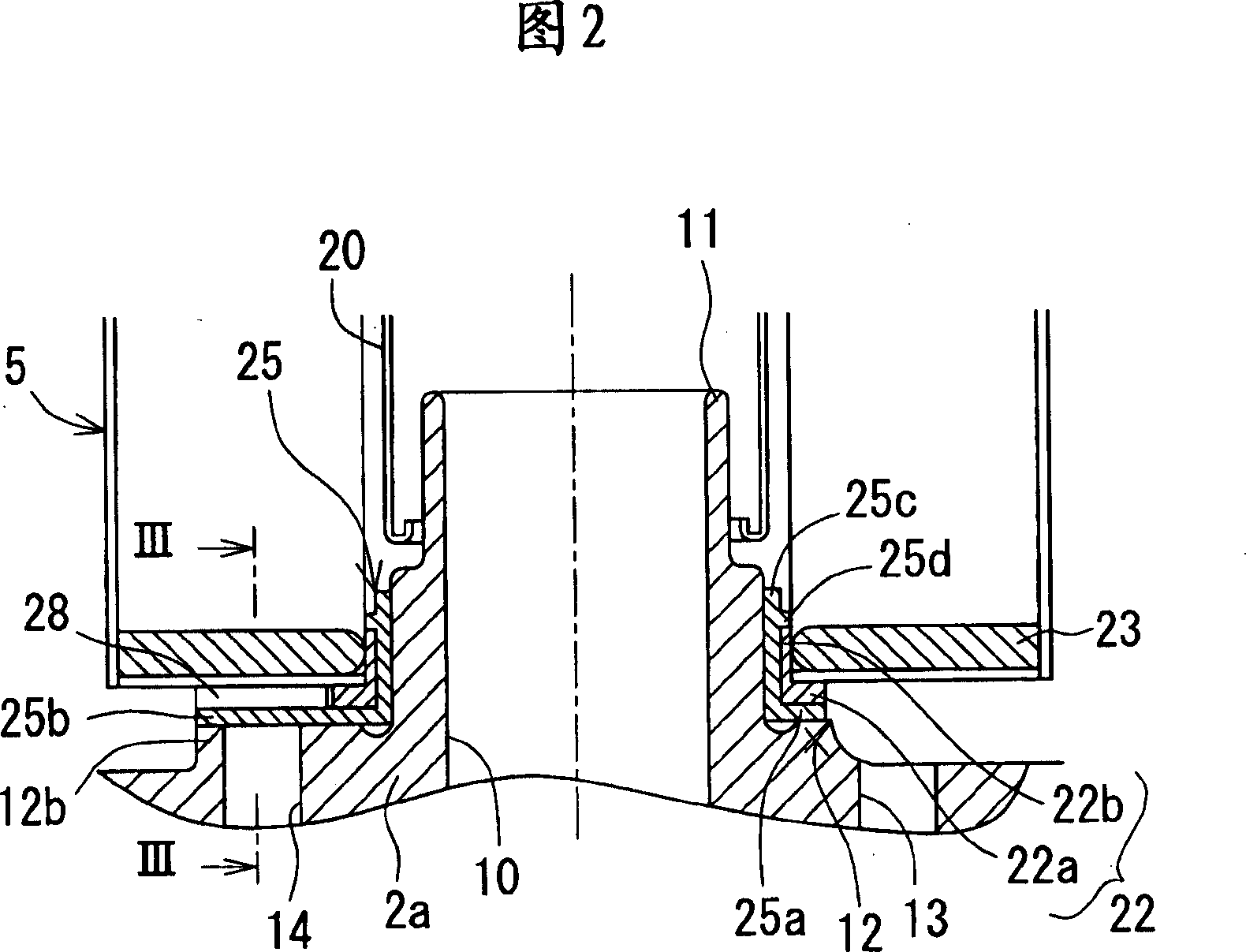

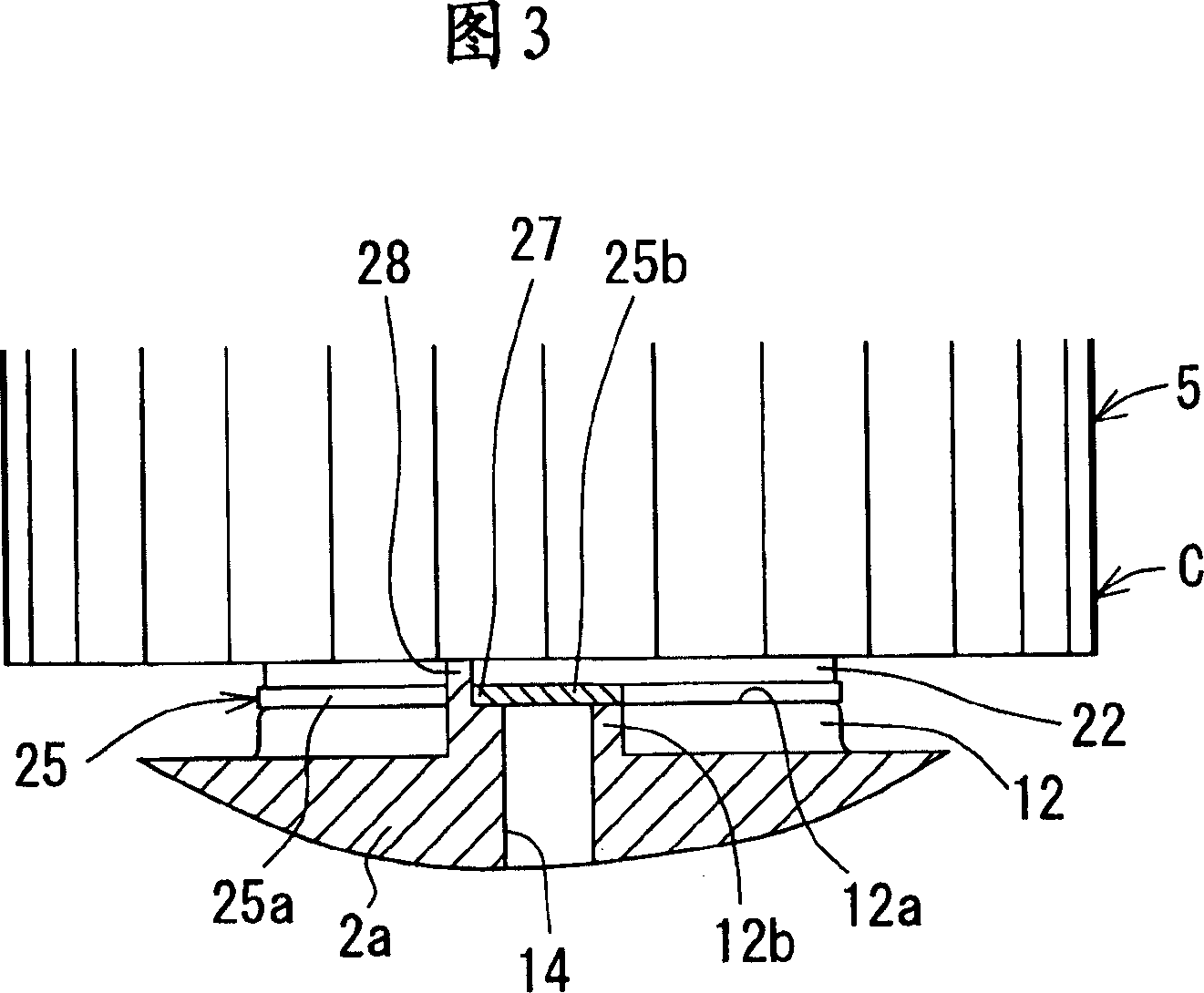

[0046] 1. Fluid filter

[0047] According to the fluid filter of the present embodiment, a case, a cover, a loading mechanism, a sealing member, and a rotation restricting mechanism are provided below. The fluid filter can be further equipped with a support body which will be described later, for example.

[0048] The above-mentioned "casing" only needs to form an inflow path, an outflow path, and a discharge path, and its structure, shape, material, etc. are not particularly limited. The case may have, for example, a bottomed cylindrical shape with an open top.

[0049] In the bottom of the above-mentioned housing, for example, an inflow passage is formed, and a discharge passage is formed in a protruding portion thicker than the bottom of the housing, and the opening of the discharge passage is at a position higher than the opening of the inflow passage. The passage and the inflow passage may be arranged on the same circumference. Thereby, the casing can be miniaturized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com