Foamable thermoplastic resin particles and method for producing same

A thermoplastic resin and a technology for a manufacturing method are applied in the field of manufacturing thermoplastic resin foamed moldings, and achieve the effects of simple manufacturing equipment and processes and less fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] (Manufacture of expandable polystyrene resin pellets)

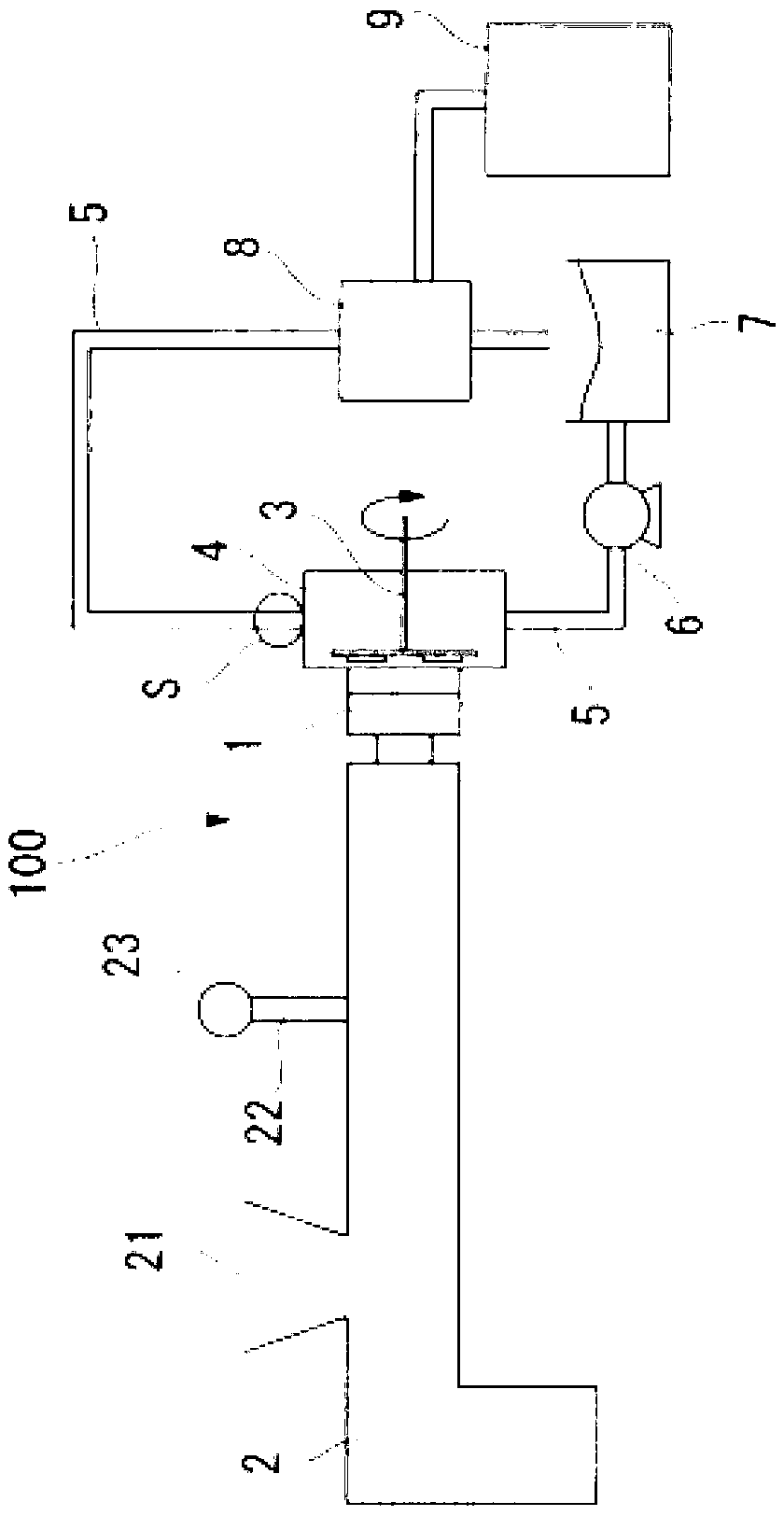

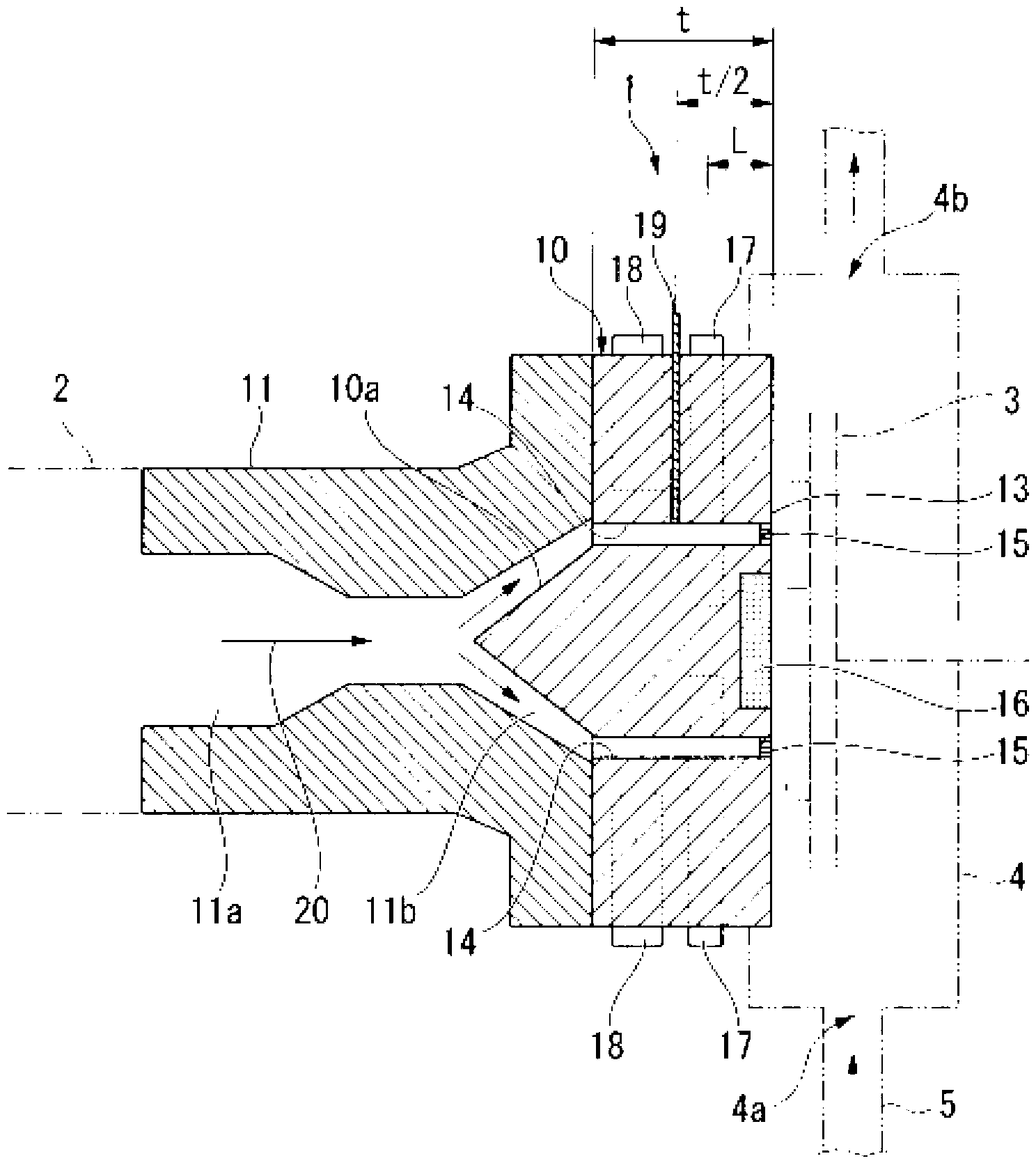

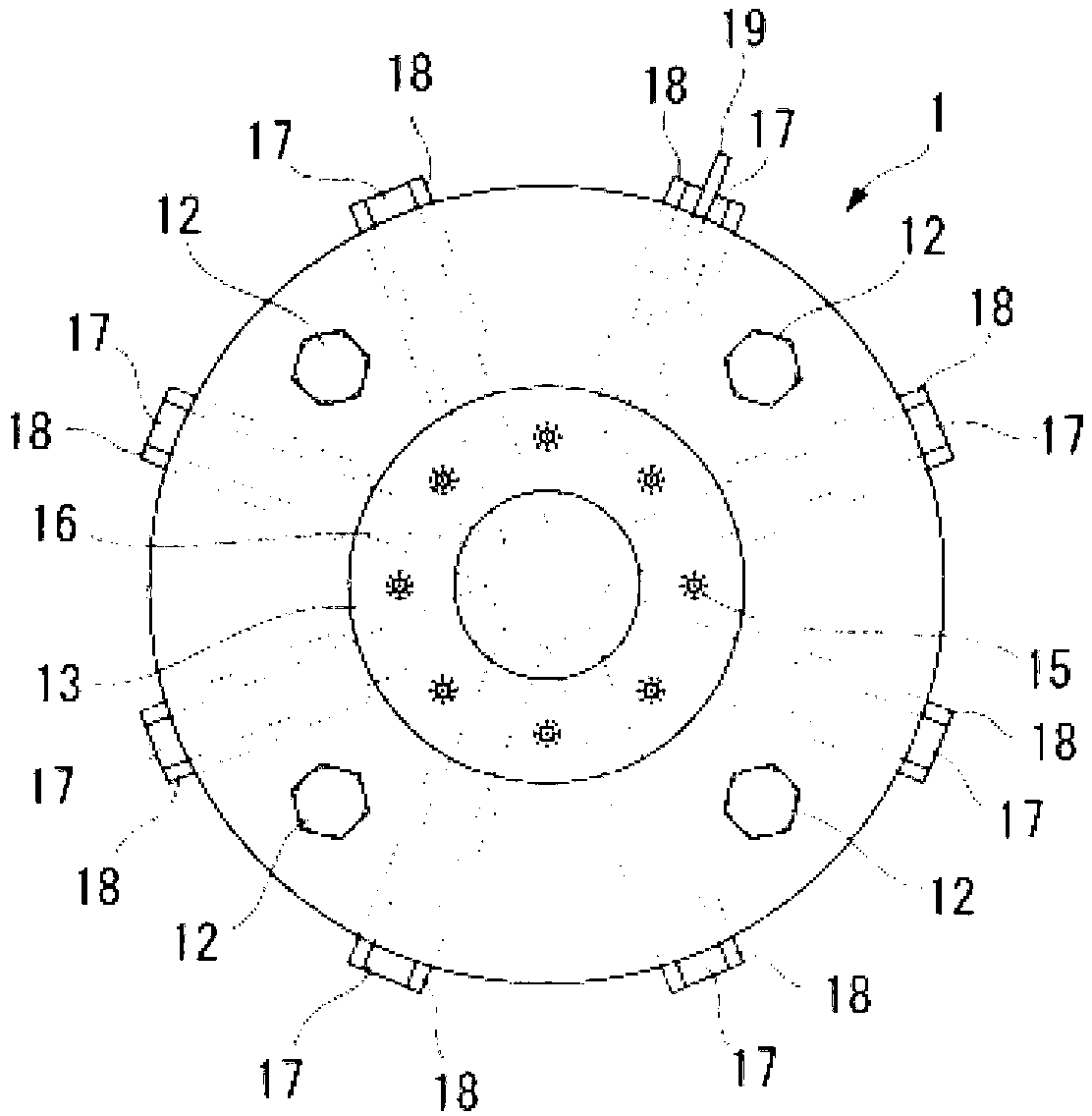

[0100] exist figure 1 As shown in extruder 2, install the figure 2 and image 3 The shown granulation mold 1 composed of a mold base 11 and a mold main body 10 produces expandable polystyrene resin pellets. use figure 2 and image 3 The temperature measuring body 19 shown switches and controls all the cylindrical heaters 17 and the short heaters 18 to adjust the temperature of the mold main body 10 of the granulation mold 1 .

[0101] As the base resin, 0.3 parts by mass of talc fine powder was uniformly mixed in advance with 100 parts by mass of polystyrene resin (manufactured by TOYO STYRENE Co., Ltd., trade name "HRM-10N") with a tumble mixer. The mixture was supplied to a single-screw extruder with a diameter of 90 mm, and the resin was heated and melted. Thereafter, 6 parts by mass of isopentane as a foaming agent was injected in the middle of the extruder with respect to 100 parts by mass of the resi...

Embodiment 2

[0145]Except having set the resin temperature to 200 degreeC (195 degreeC in Example 1), it carried out similarly to Example 1, and produced the expandable resin particle, the pre-expanded particle, and the expanded molding.

Embodiment 3

[0147] Except that the resin temperature is 200°C (195°C in Example 1) and the mold temperature is 195°C (185°C in Example 1), the same operation as Example 1 is performed to produce expandable resin particles, pre-expanded Foam particles and foam moldings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com