Slag discharge condition monitoring apparatus and method for monitoring slag discharge condition

A monitoring device and status technology, which is applied in the direction of combustion methods, granular/powdered fuel gasification, incinerators, etc., can solve the problems of reduced measurement accuracy, inability to fully monitor the status and changes of slag discharge, and prevent the reduction of measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

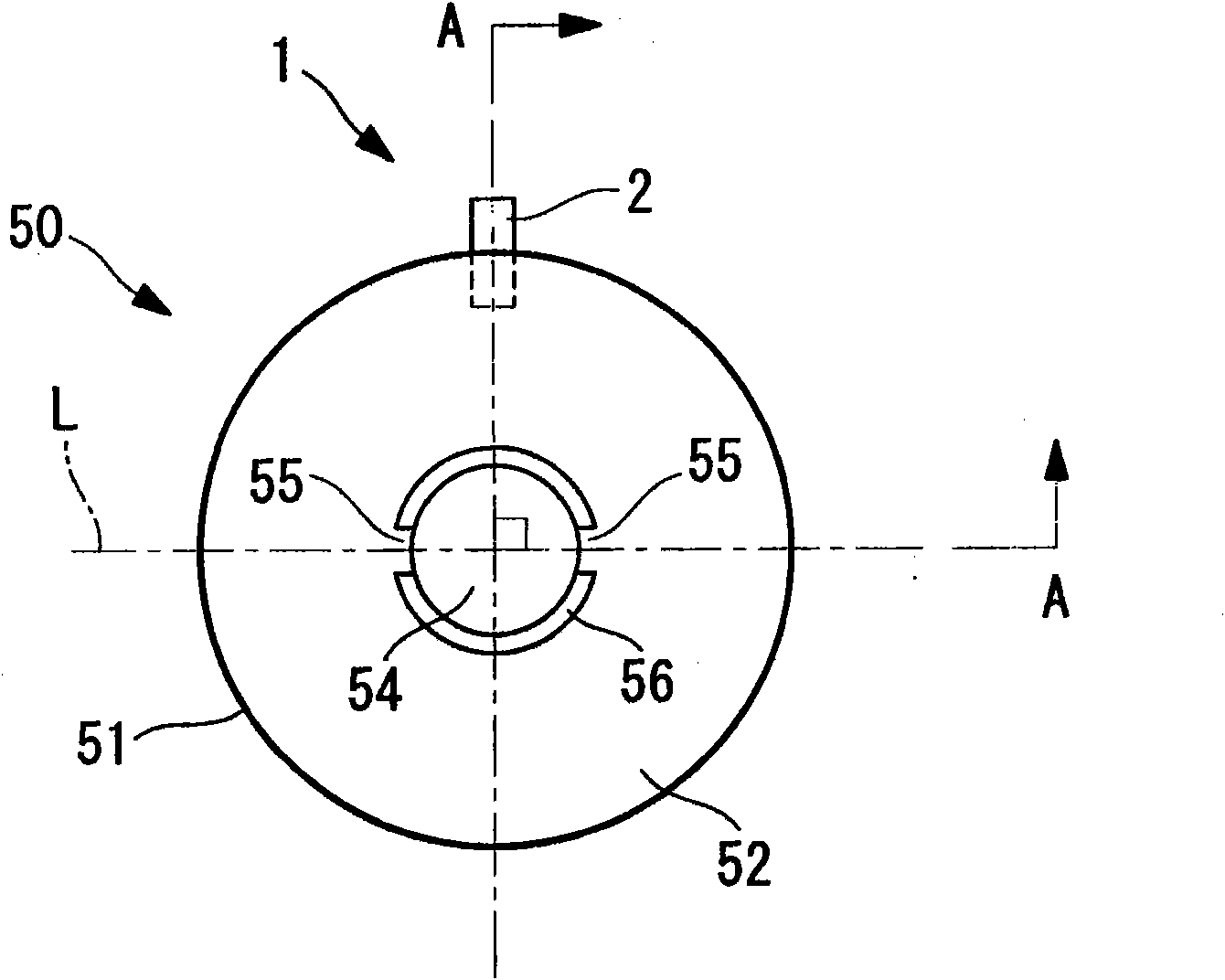

[0052] Below, refer to figure 1 and figure 2 A slag discharge status monitoring device according to a first embodiment of the present invention will be described.

[0053] figure 1 It is a top view explaining the structure of the slag discharge state monitoring apparatus of this embodiment. figure 2 is description figure 1 The A-A cross-sectional view of the outline of the slag discharge status monitoring device.

[0054] like figure 1 and figure 2 As shown, the slag discharge status monitoring device 1 of this embodiment is installed in a combustion furnace (furnace facility) 50 of a coal gasification furnace of a coal gasification facility, and monitors the discharge status of molten slag generated in the combustion furnace 50. , or an alarm is issued when it falls intermittently.

[0055] The combustion furnace 50 is provided with: a combustion furnace main body (furnace) 51 that burns pulverized coal or charcoal inside, a furnace bottom 52 where the burned coal a...

no. 2 approach

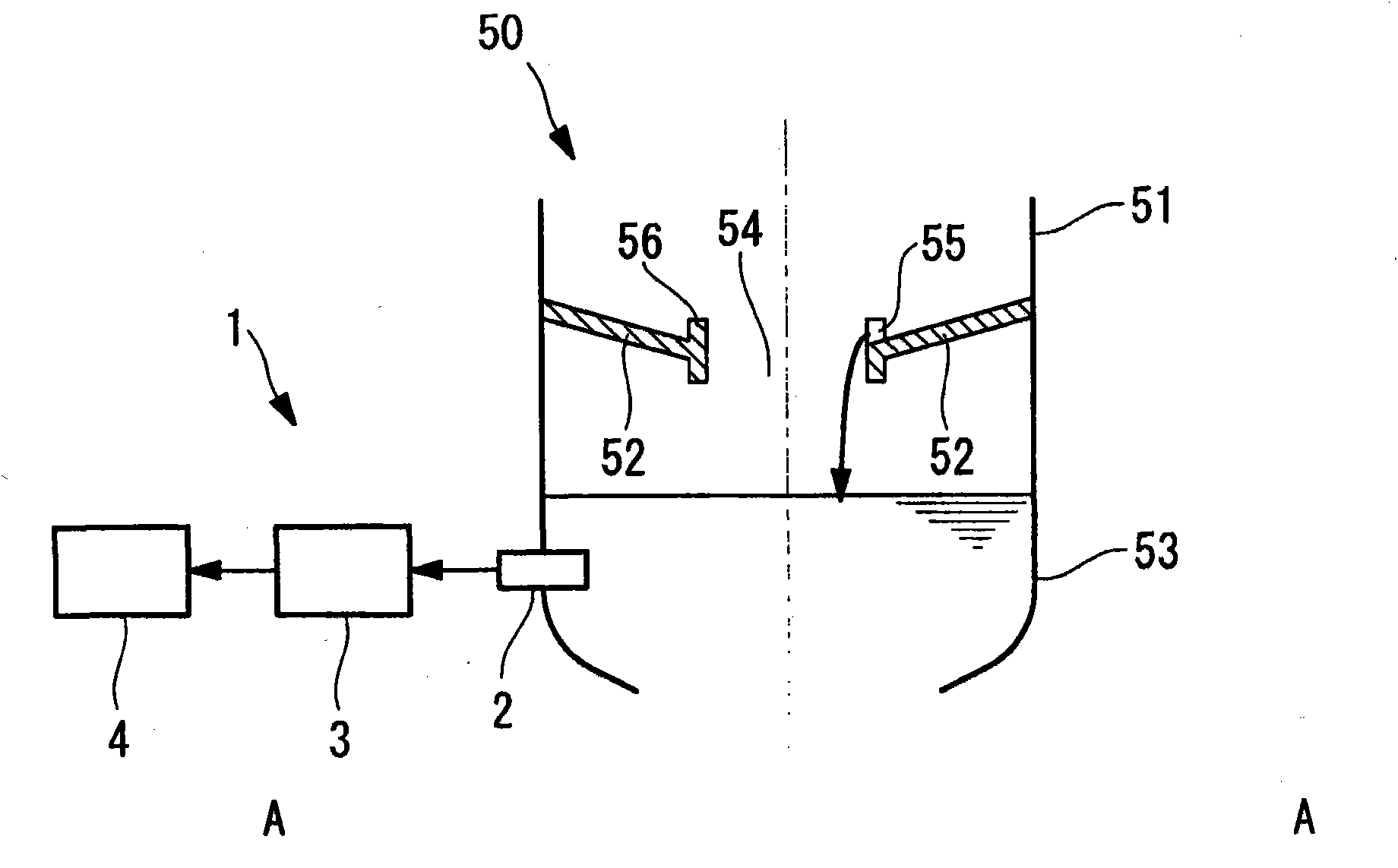

[0083] Below, refer to image 3 and Figure 4 A second embodiment of the present invention will be described.

[0084] The basic configuration of the slag discharge status monitoring device of this embodiment is the same as that of the first embodiment, but the arrangement of the underwater sound detector is different from that of the first embodiment. Therefore, in this embodiment, only the image 3 and Figure 4 The arrangement of the underwater sounder will be described, and the description of other constituent elements and the like will be omitted.

[0085] image 3 It is a top view explaining the structure of the slag discharge state monitoring apparatus of this embodiment. Figure 4 is description image 3 The B-B cross-sectional view of the outline of the slag discharge status monitoring device.

[0086] In addition, the same code|symbol is attached|subjected to the same component as 1st Embodiment, and the description is abbreviate|omitted.

[0087] like imag...

no. 3 approach

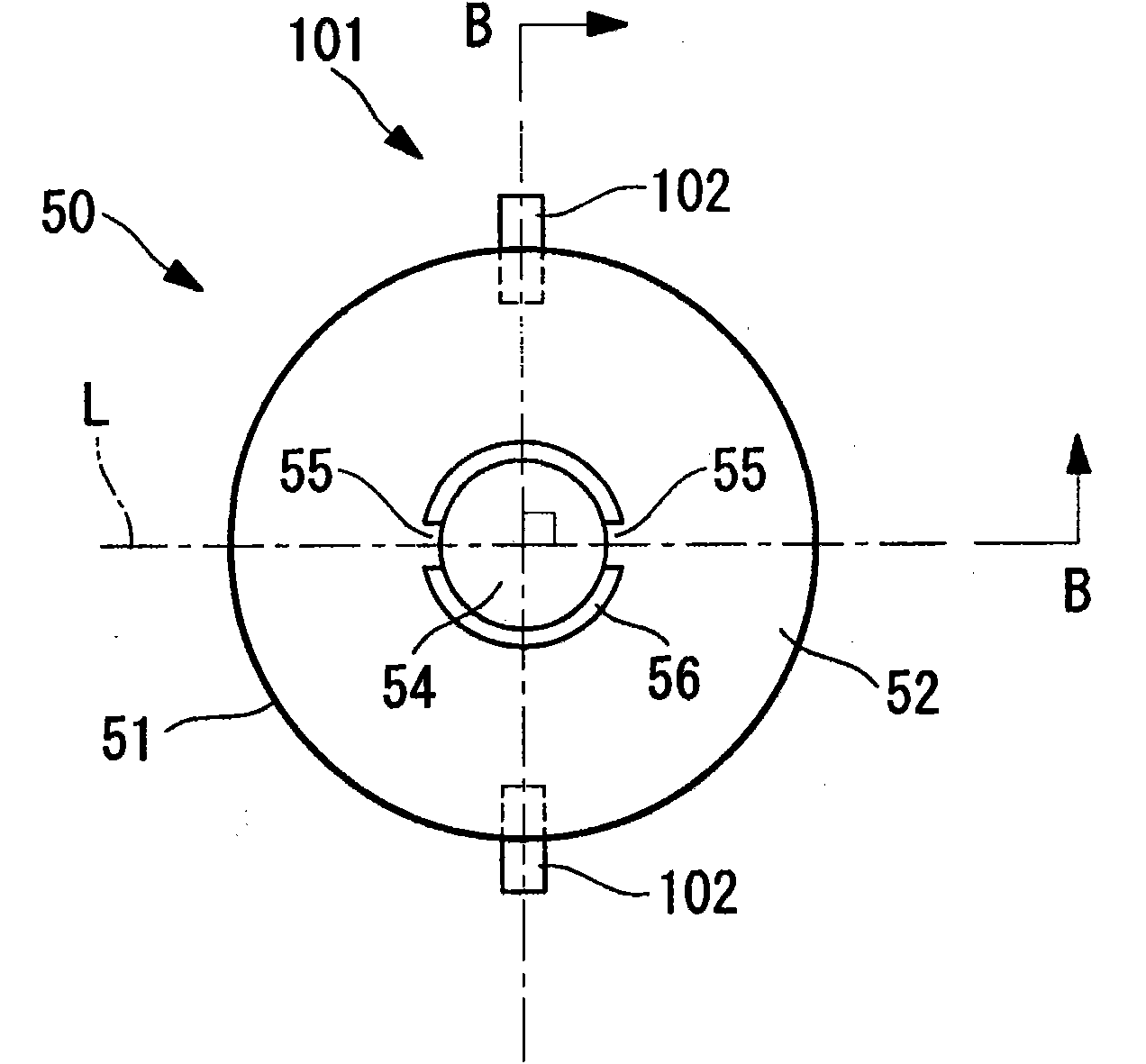

[0097] Below, refer to Figure 5 and Image 6 A third embodiment of the present invention will be described.

[0098] The basic configuration of the slag discharge status monitoring device of this embodiment is the same as that of the first embodiment, but the arrangement of the underwater sound detector is different from that of the first embodiment. Therefore, in this embodiment, using Figure 5 and Image 6 Only the arrangement of the underwater sound detector will be described, and the description of other components and the like will be omitted.

[0099] Figure 5 It is a top view explaining the structure of the slag discharge state monitoring apparatus of this embodiment. Image 6 is description Figure 5 The C-C cross-sectional view of the outline of the slag discharge status monitoring device.

[0100] In addition, the same code|symbol is attached|subjected to the same component as 1st Embodiment, and the description is abbreviate|omitted.

[0101] like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com