Optical body, method for manufacturing same, window member, sliding window, and sunlight blocking device

A technology of optical body and optical layer, applied in the field of optical body, can solve problems such as glare and reflection, and achieve the effect of suppressing glare and reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach ( 100

[0085] 3. Third embodiment (an example of a louver-type transflective layer)

[0086] 4. Fourth embodiment (example in which a light scatterer is provided in an optical film)

[0087] 5. Fifth embodiment (in which an example of a self-cleaning layer is provided)

[0088] 6. Sixth embodiment (an example in which the optical film is applied to a blind device)

[0089] 7. Seventh embodiment (an example in which the optical film is applied to a rolling screen device)

[0090] 8. Eighth embodiment (in which the optical film is applied to a construction example)

no. 1 approach

[0092] [Structure of optical film]

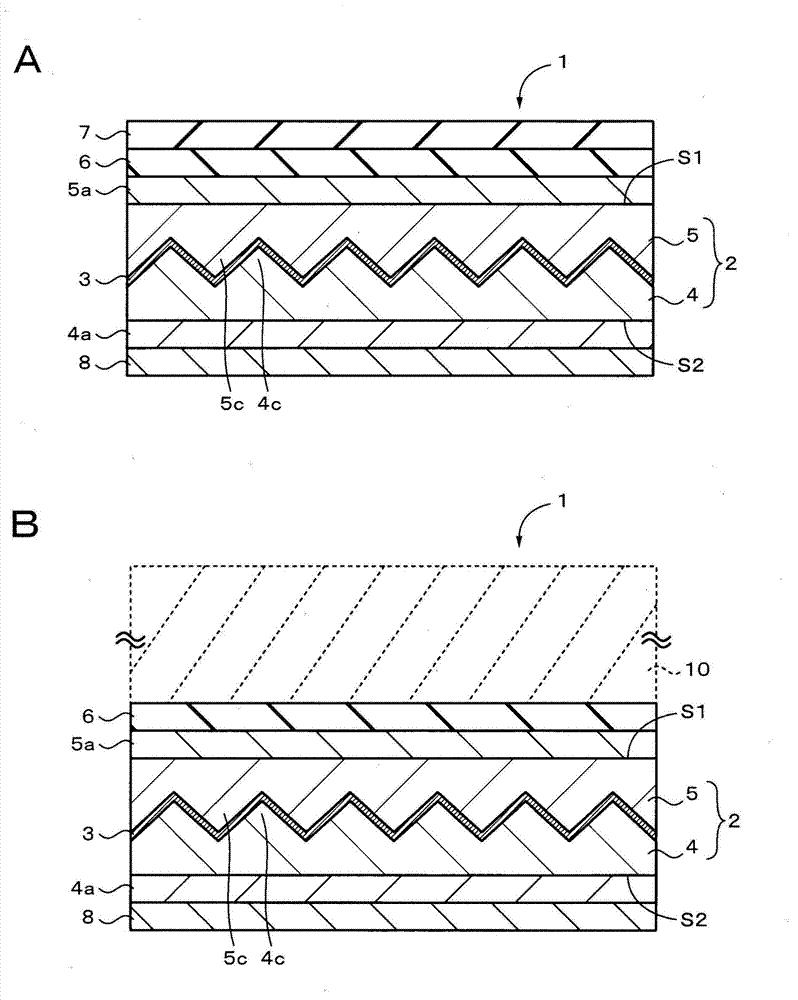

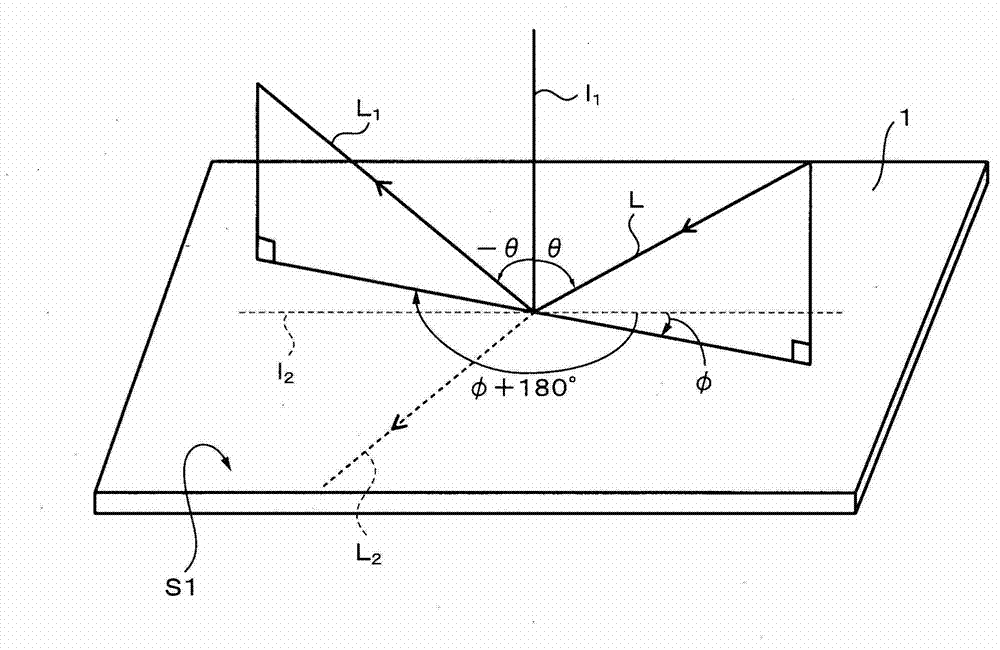

[0093] figure 1 A is a cross-sectional view showing one example of the configuration of the optical film according to the first embodiment of the present invention. figure 1 B is a sectional view showing an example in which the optical film according to the first embodiment of the present invention is attached to an adherend. The optical film 1 as an optical body is an optical film having so-called directional reflection performance. Such as figure 1 As shown in A, the optical film 1 includes an optical layer 2 having a concavo-convex interface therein, and a transflective layer 3 provided on the interface of the optical layer 2 . The optical layer 2 includes a first optical layer 4 having a first surface of a concavo-convex shape and a second optical layer 5 having a second surface of a concavo-convex shape. The interface in the optical layer is formed by a first surface and a second surface each having a concavo-convex shape and being...

no. 2 approach

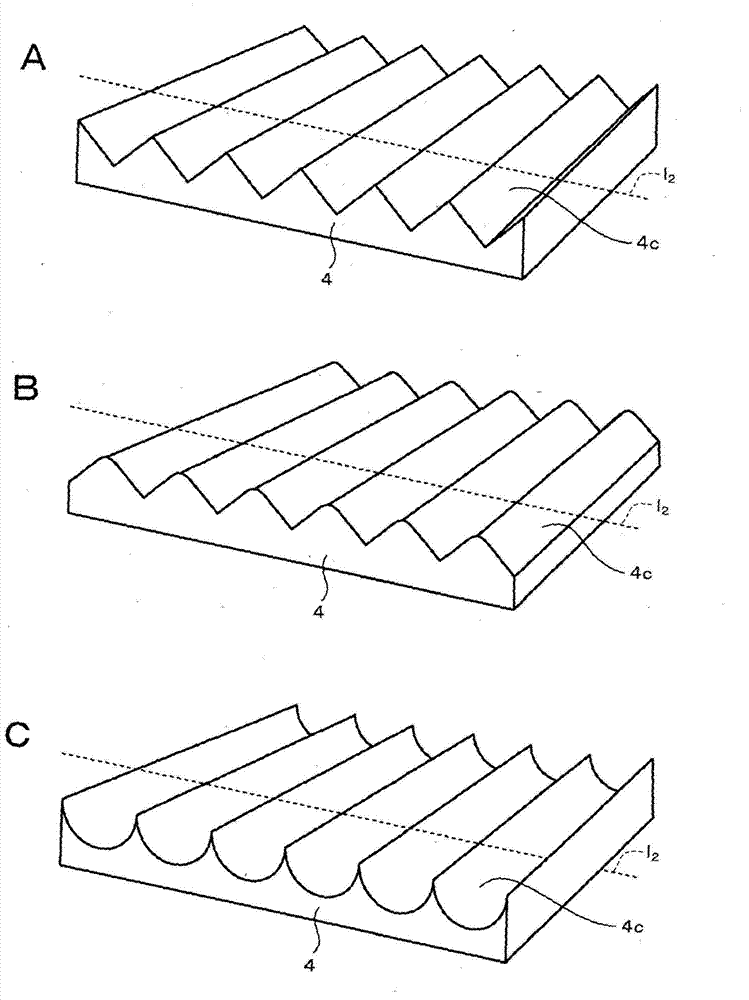

[0184] Figures 13 to 16 An example of the configuration of the structure formed in the optical film according to the second embodiment of the present invention is shown. Parts in the second embodiment corresponding to parts in the first embodiment are indicated by the same reference numerals. The second embodiment differs from the first embodiment in that structures 4 c are two-dimensionally arranged on the main surface of the first optical layer 4 . Preferably, the two-dimensional arrangement represents the two-dimensional arrangement in the most densely packed state. This is because such an arrangement can improve directional reflectivity.

[0185] Such as Figure 13 As shown in A to 13C, for example, cylindrical structures (cylinders) 4 c are arranged perpendicularly to each other on the principal surface of the first optical layer 4 . Specifically, the first structures 4c aligned in the first direction and the second structures 4c aligned in the second direction perpe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com