Closed frequency-adjustable resonant microwave reaction chamber

A microwave reaction and closed technology, applied in the field of resonant microwave reaction chamber, can solve the problems of high cost, inconvenient use, and inability to meet frequency reconfiguration, and achieve the effect of continuous frequency adjustment and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

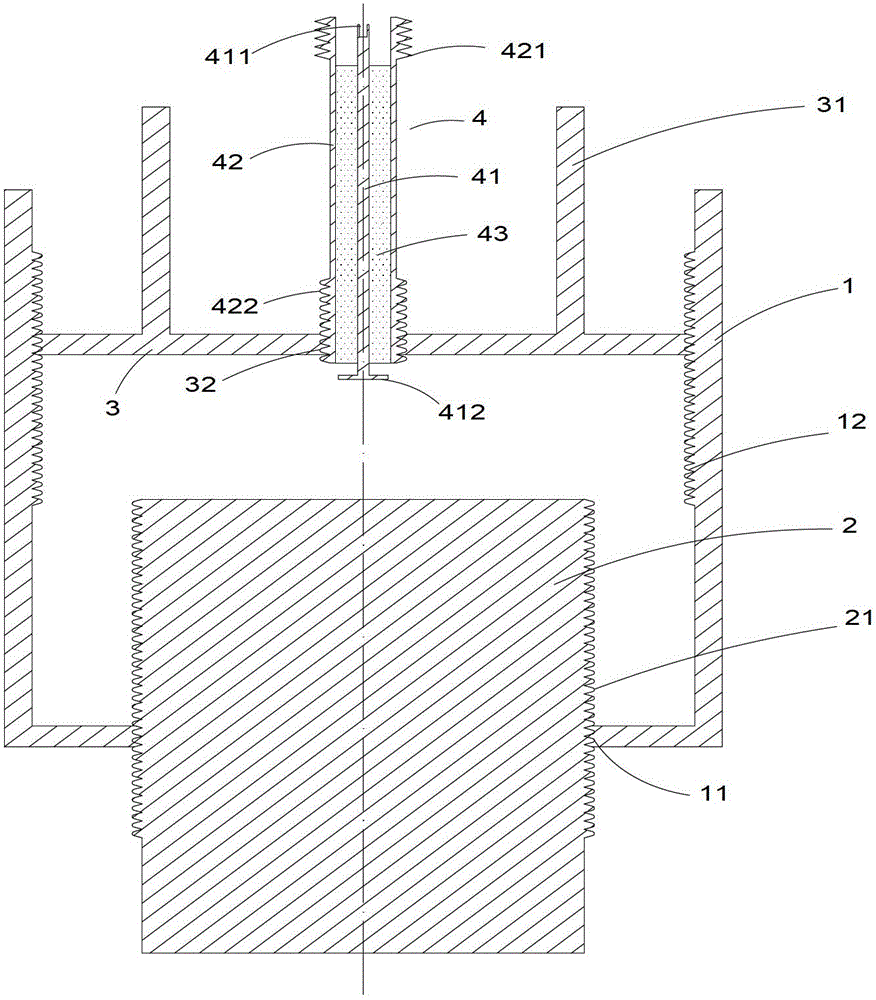

[0028] Embodiment 1: as figure 1 As shown, a resonant microwave reaction chamber includes an outer conductor 1 , an inner conductor 2 , a closing cover 3 , and a feeding coaxial 4 . It is characterized in that the outer conductor 1 is a cylindrical metal cavity, and there is a cylindrical bottom hole 11 in the center of the bottom, and the inner wall is threaded; the cylindrical inner conductor 2 enters the interior of the outer conductor 1 through the bottom hole 11, and the upper half of the inner conductor 2 The FM thread 21 with a dome cooperates with the thread on the wall of the bottom hole 11 to keep the outer conductor 1 and the inner conductor 2 in electrical contact, and at the same time, the length of the inner conductor 2 entering the outer conductor 1 can be adjusted; the outer conductor 1 is close to the inner wall of the top The closed thread 12 with a dome is threaded with the outer edge of the axisymmetric closed cover 3 to keep the outer conductor 1 and the c...

Embodiment 2

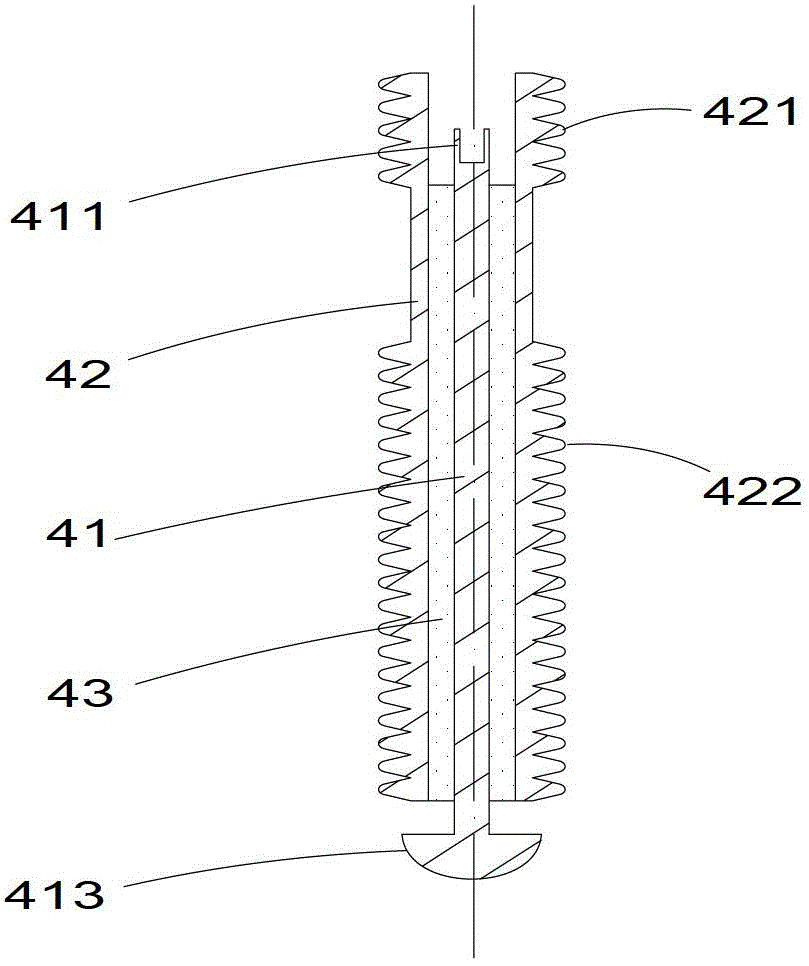

[0036] Embodiment 2: as figure 1 , figure 2 As shown, on the basis of Embodiment 1, the end of the feed coaxial inner conductor 41 entering the outer conductor 1 is connected to a hemispherical feed end hemisphere 413.

Embodiment 3

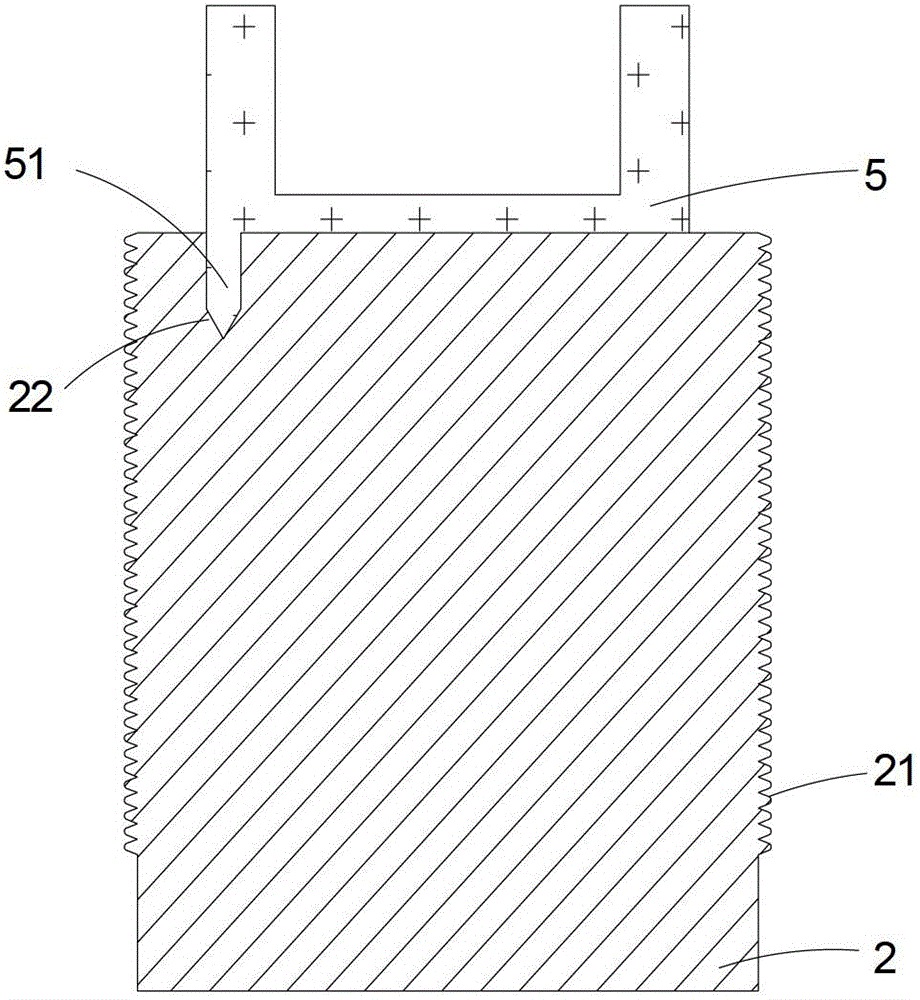

[0037] Embodiment 3: as figure 1 , image 3 and Figure 4 As shown, on the basis of Embodiment 1, a barrel-shaped pallet 5 with a diameter smaller than the inner conductor 2 is introduced, and three fixed small cylinders 51 protrude downward from its bottom end, which are smaller than the three concave cylinders at the top of the inner conductor 2. The hole 22 fits and is fixed, and the bottom of the concave cylindrical hole 22 is tapered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com