Motor load distribution control method and motor load distribution control device

A technology of load distribution and control device, applied in the direction of roll speed control, etc., can solve the problems of motor load imbalance, affecting rolling efficiency and product quality, motor overheating, etc., to ensure the effect of rolling efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

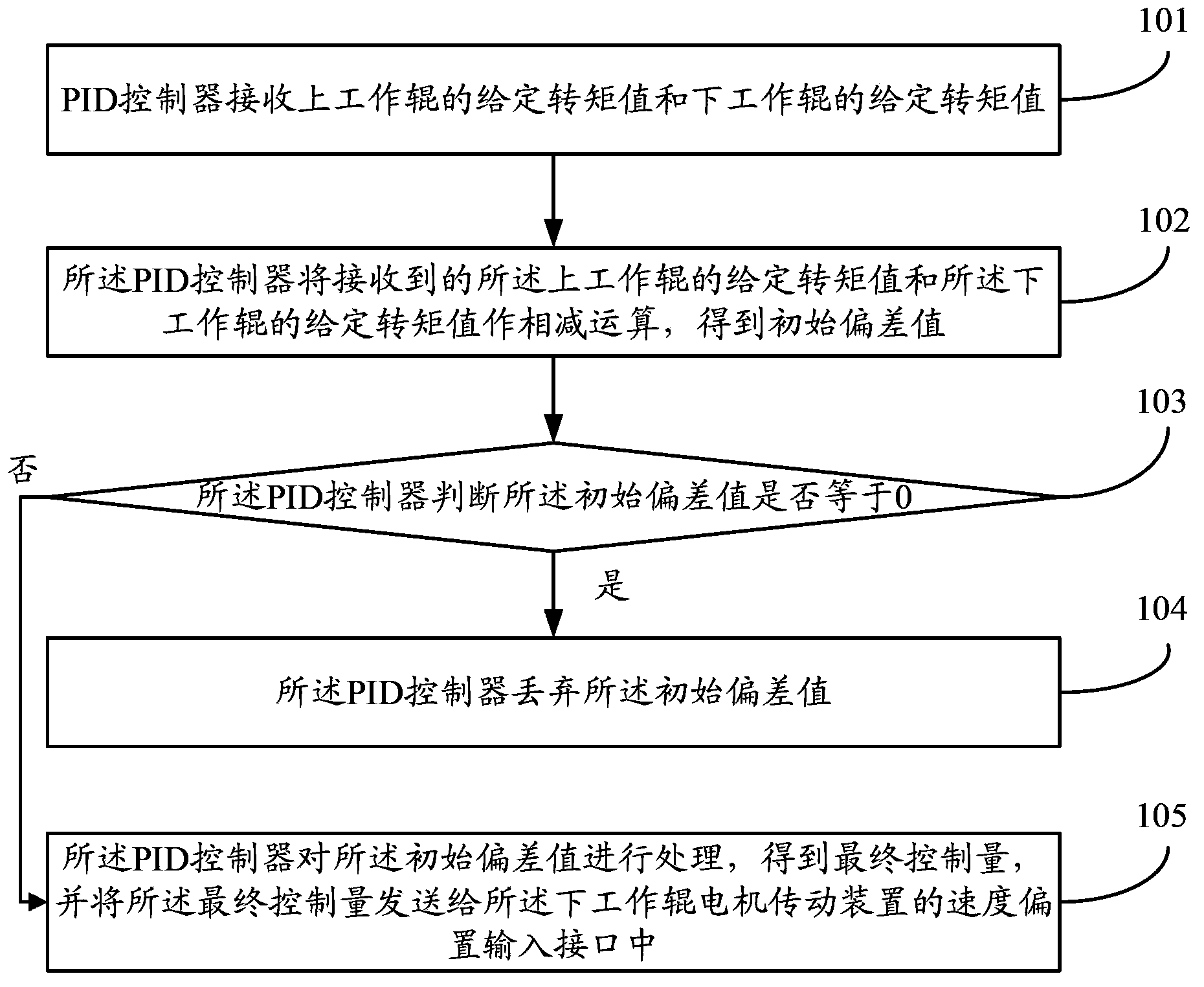

[0044] Such as figure 1 As shown, it is a schematic flowchart of a motor load distribution control method provided by an embodiment of the present invention, including the following steps:

[0045] Step 101, the PID controller receives the given torque value of the upper work roll and the given torque value of the lower work roll.

[0046] Specifically, the PID controller respectively receives the given torque value of the upper work roll sent by the upper work roll motor drive through the field bus and the given torque of the lower work roll sent by the lower work roll motor drive through the field bus value.

[0047] In addition, the PID controller can receive the given torque value of the upper work roll and the given torque value of the lower work roll according to the preset frequency. Make sure.

[0048] Step 102, the PID controller subtracts the received given torque value of the upper work roll and the given torque value of the lower work roll to obtain an initial d...

Embodiment 2

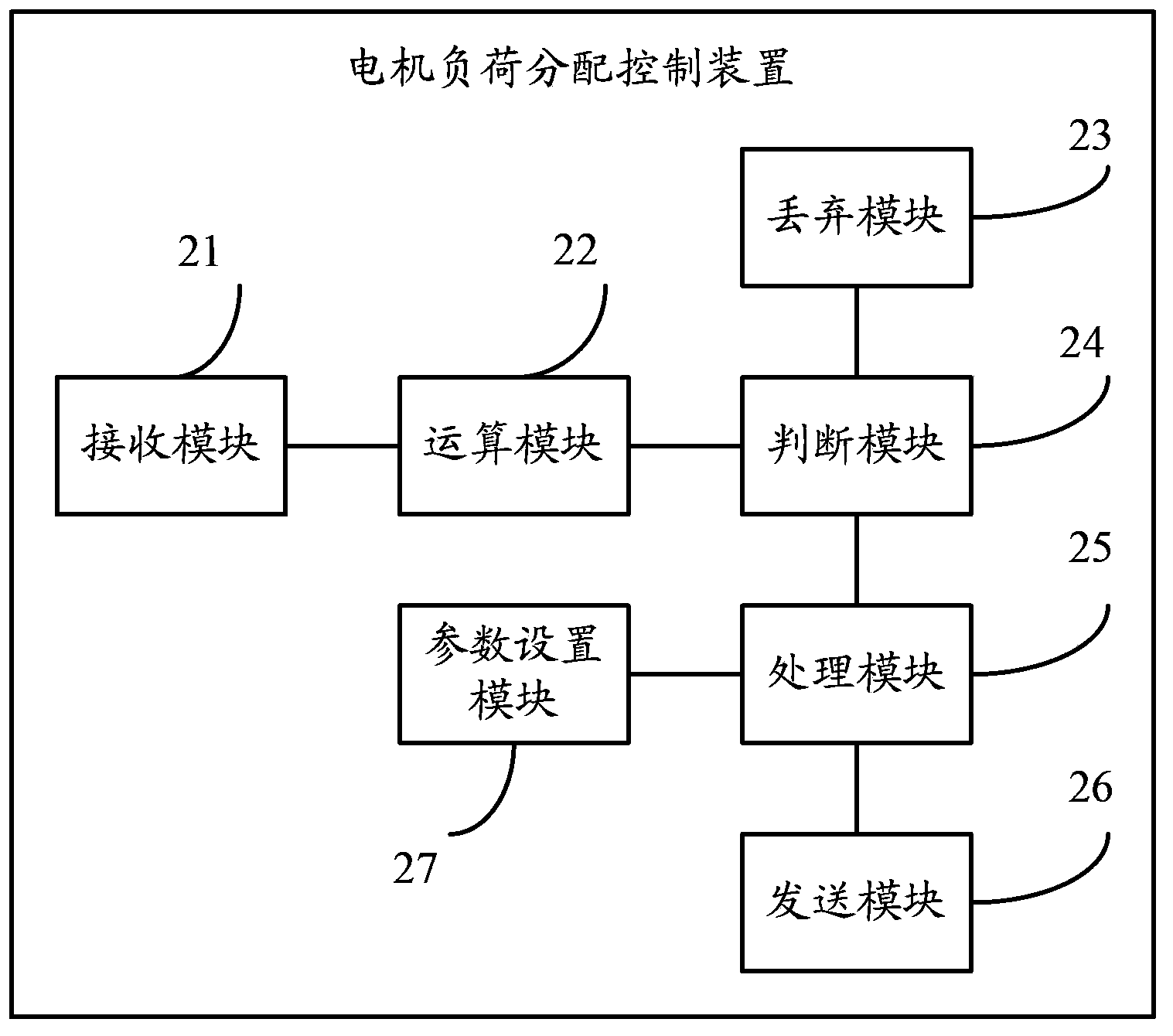

[0061] Such as figure 2 As shown, it is a schematic structural diagram of a motor load distribution control device provided by an embodiment of the present invention. The motor load distribution control device is a PID controller, and the PID controller includes the following modules:

[0062] A receiving module 21, configured to receive a given torque value of the upper work roll and a given torque value of the lower work roll;

[0063] The receiving module is also used to: respectively receive the given torque value of the upper work roll sent by the upper work roll motor drive through the field bus and the given torque of the lower work roll sent by the lower work roll motor drive through the field bus value.

[0064] An arithmetic module 22, configured to subtract the given torque value of the upper work roll received by the receiving module 21 from the given torque value of the lower work roll to obtain an initial deviation value;

[0065] A judging module 23, configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com