Rare earth aluminum magnesium alloy barrier explosion-proof material

A technology for blocking explosion-proof materials and magnesium alloys, which is applied in the field of aluminum-magnesium alloy explosion-proof materials, can solve the problems of non-corrosion resistance, limited strength, elongation, high temperature resistance and thermal crack resistance of explosion-proof materials, and achieves good explosion-proof and thermal crack resistance. Strong ability and the effect of prolonging the life of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

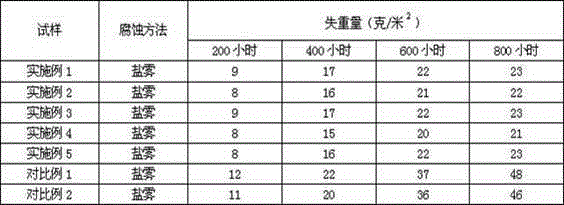

Examples

Embodiment 1

[0014] Embodiment 1: First, aluminum, magnesium and other alloying elements are smelted into alloy ingots. The elemental components and mass percentages of the ingots are: Mg0.8%, Fe0.3%, Si0.6%, Mn1.8, Cu0 .1%, Zn0.2%, rare earth metal 0.45% (specific components: Y0.1%, Ce0.1%, La0.2%, Sc0.05%), the balance is aluminum and unavoidable impurities. Then the cast ingot is rolled into 0.05-0.01mm rare earth aluminum-magnesium alloy foil, sent to the slitting machine to cut the slit, and then sent to the stretching machine to stretch into a grid-shaped metal sheet.

Embodiment 2

[0015] Embodiment 2: First, aluminum, magnesium and other alloying elements are smelted into alloy ingots. The elemental components and mass percentages of the ingots are: Mg1.8%, Fe0.5%, Si0.5%, Mn1.6, Cu0 .2%, Zn0.1%, rare earth metal 0.50% (specific components: Y0.1%, Ce0.1%, La0.2%, Sc0.1%), the balance is aluminum and unavoidable impurities. Then the cast ingot is rolled into 0.05-0.01mm rare earth aluminum-magnesium alloy foil, sent to the slitting machine to cut the slit, and then sent to the stretching machine to stretch into a grid-shaped metal sheet.

Embodiment 3

[0016] Embodiment 3: First, aluminum, magnesium and other alloying elements are smelted into alloy ingots. The elemental components and mass percentages of the ingots are: Mg1.2%, Fe0.4%, Si0.5%, Mn1.2, Cu0 .15%, Zn0.15%, rare earth metal 0.77% (specific components: Y0.15%, Ce0.15%, La0.4%, Sc0.07%, the balance is aluminum and unavoidable impurities. Then the The cast ingot is rolled into 0.05-0.01mm rare earth aluminum-magnesium alloy foil, sent to the slitting machine to cut the slit, and then sent to the stretching machine to stretch into a grid-shaped metal sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com