Non-floor type bracket bearing shear pin and construction method thereof

A shear pin and bracket technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of long steel bar outreach, long turnover period, instability of support system, etc., and achieve increased shear cross section. , Increase the contact area and improve the effect of supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

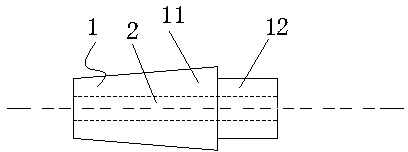

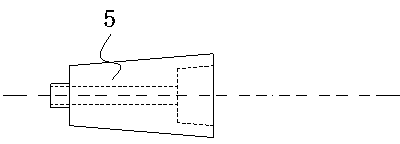

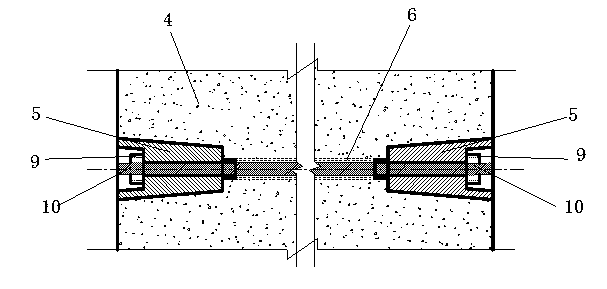

[0028] Example: The lower structure of the approach bridge of Dongsheng Bridge in Ordos City, the pier columns are mostly high pier columns, the length of the cover beam is 23.64m, the cantilever length of the cover beam is 7.52m, and the concrete cover beam is 142m 3 , using the load-bearing shear pin of the non-floor bracket of the present invention to carry out the construction without the ground bracket method, the bracket is a truss structure, and the truss support system uses the shear pins arranged in the pier column to transfer the load to the pier column to support the entire truss and cover beam loads. The principle is: the exposed cylindrical tail of the shear pin bears the load transmitted by the bracket, the shear pin is closely attached to the concrete of the pier column, and the load transmitted by the bracket is transferred to the pier column through the shear pin, and finally reaches the pier column Forced support.

[0029] Take the lower structure of the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com