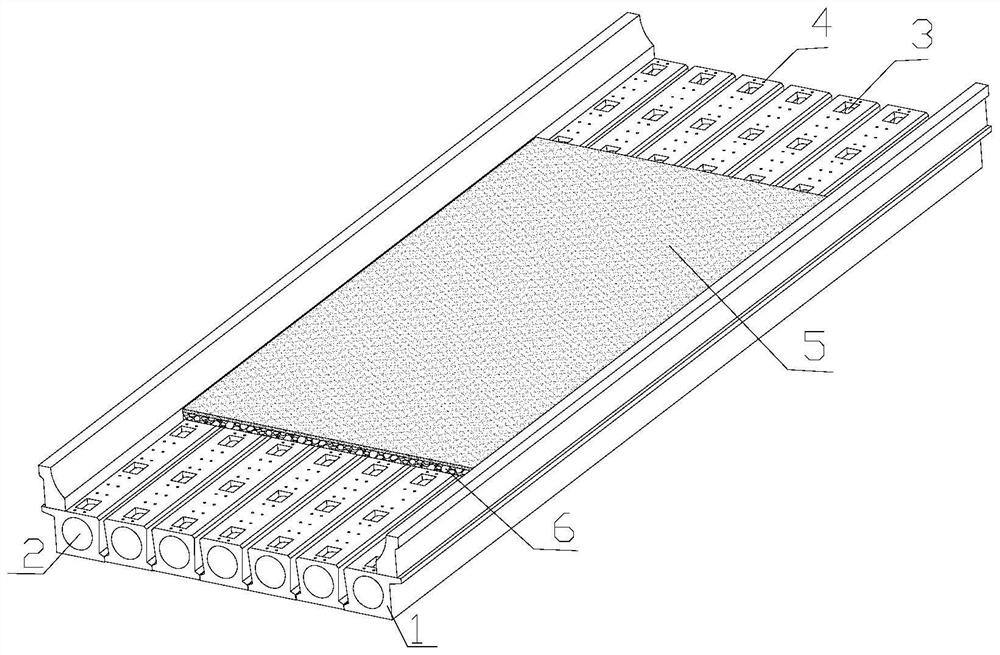

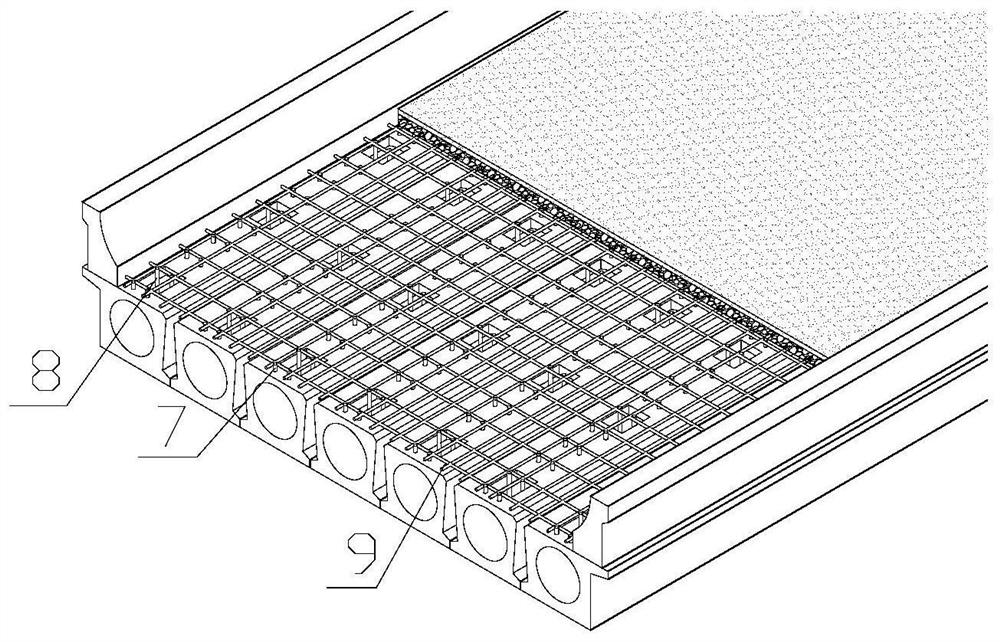

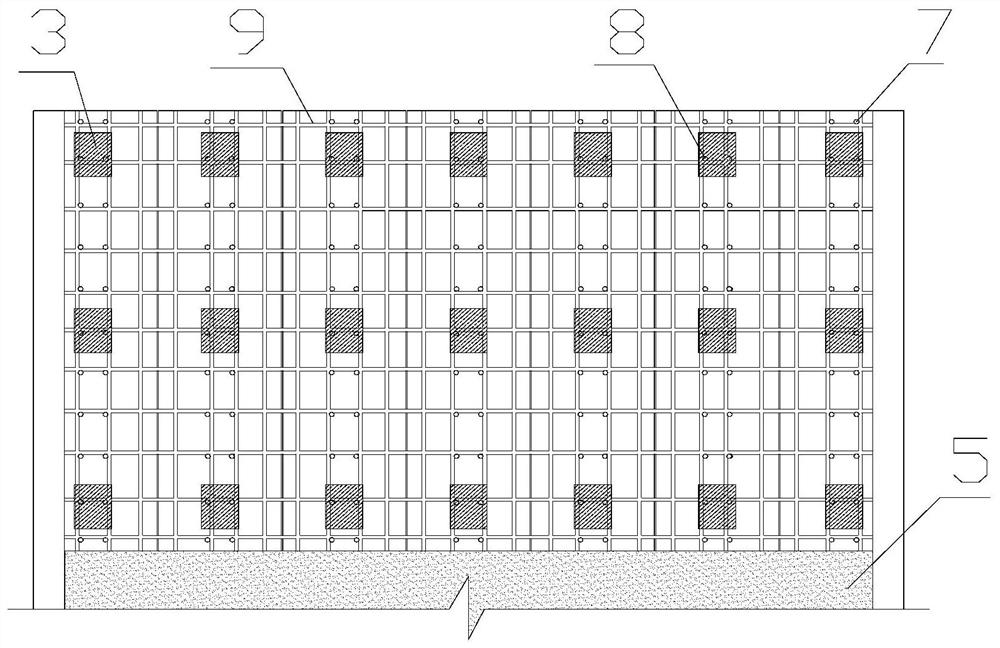

A Shear Strengthening Method for Hollow Slab Beams Based on High Performance Composite Materials

A hollow slab beam, composite material technology, applied in bridge reinforcement, bridge materials, bridges, etc., can solve the problems of detachment of steel plate and concrete, poor bonding ability of new and old concrete, long construction period, etc., to increase shear and bending resistance. Stiffness, shortening the time of closed traffic, the effect of improving the lateral connection of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in more detail below in conjunction with the preferred embodiments of the present invention. The embodiment selected is the shear resistance of a hollow slab girder bridge on an expressway in 2019. For the reinforcement project, the effect of the reinforcement method is verified through load experiments before and after reinforcement. It should be pointed out that: the described embodiment is only an embodiment of the present invention, which is illustrative and intended to explain the present invention, but should not be construed as a limitation of the present invention. The beam length of the selected embodiment is 20 meters, and the cross-section form is circular, but for other hollow slab girder bridges with different lengths and cross-section forms such as square and ellipse, the method of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com