Gas-state tester of porosity

A technology of tester and porosity, which is applied in the field of tester, can solve the problems of forgetting the test board, long time, abnormal test results, etc., and achieve the effect of avoiding abnormal test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

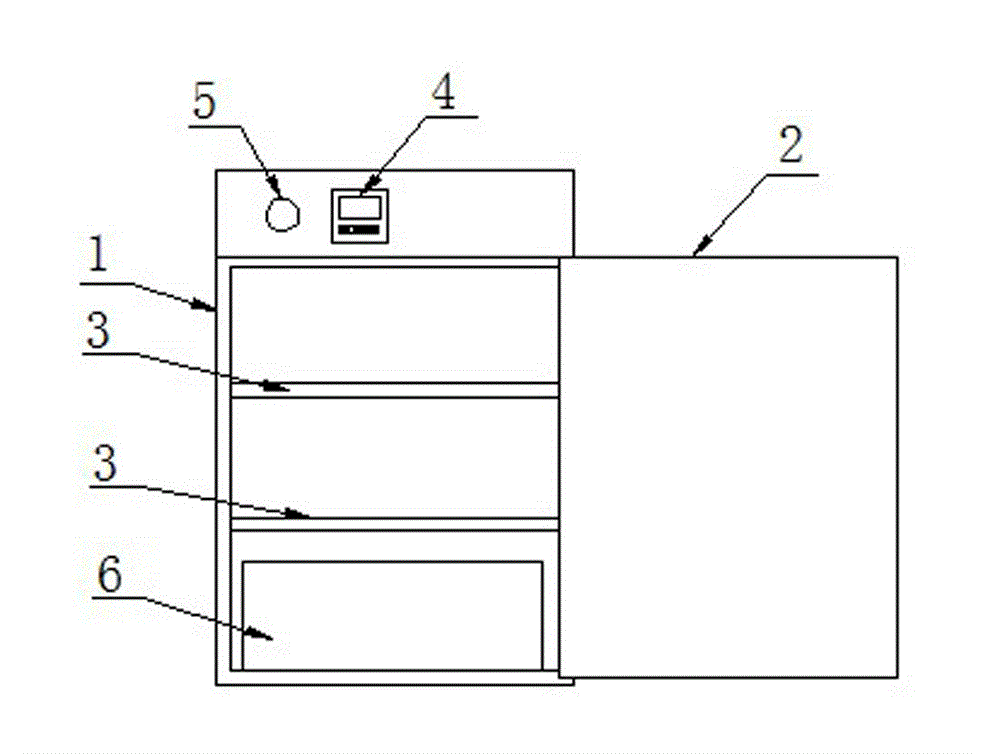

[0014] Embodiment: A gaseous porosity tester, comprising a cabinet body 1 and a cabinet door 2, the cabinet door can seal the cabinet body, and at least one support plate for placing a test board is provided at intervals inside the cabinet body 3. The adjacent support plates are located in the cabinet at an interval between the upper and lower positions. The support plate has a number of air holes, and the cabinet is equipped with a liquid storage container for placing volatile acidic liquids for testing. A timer is installed on the cabinet 4 and an alarm 5, and the timer is electrically connected to the alarm.

[0015] The cabinet body 1 is a titanium steel (316L stainless steel) cabinet body, and the cabinet door 2 is a titanium steel cabinet door.

[0016] The support plate 3 is uniformly covered with the ventilation holes at intervals.

[0017] The support plate 3 is a polyethylene plastic support plate.

[0018] A plastic basket 6 is placed at the inner bottom of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com