Hardness testing method

A test method and hardness technology, applied in the field of materials, can solve problems such as limited application occasions, impact on the rebound speed or height of the impact device, and poor operability of the detection method, so as to improve operability, good repeatability, and avoid detection results. abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

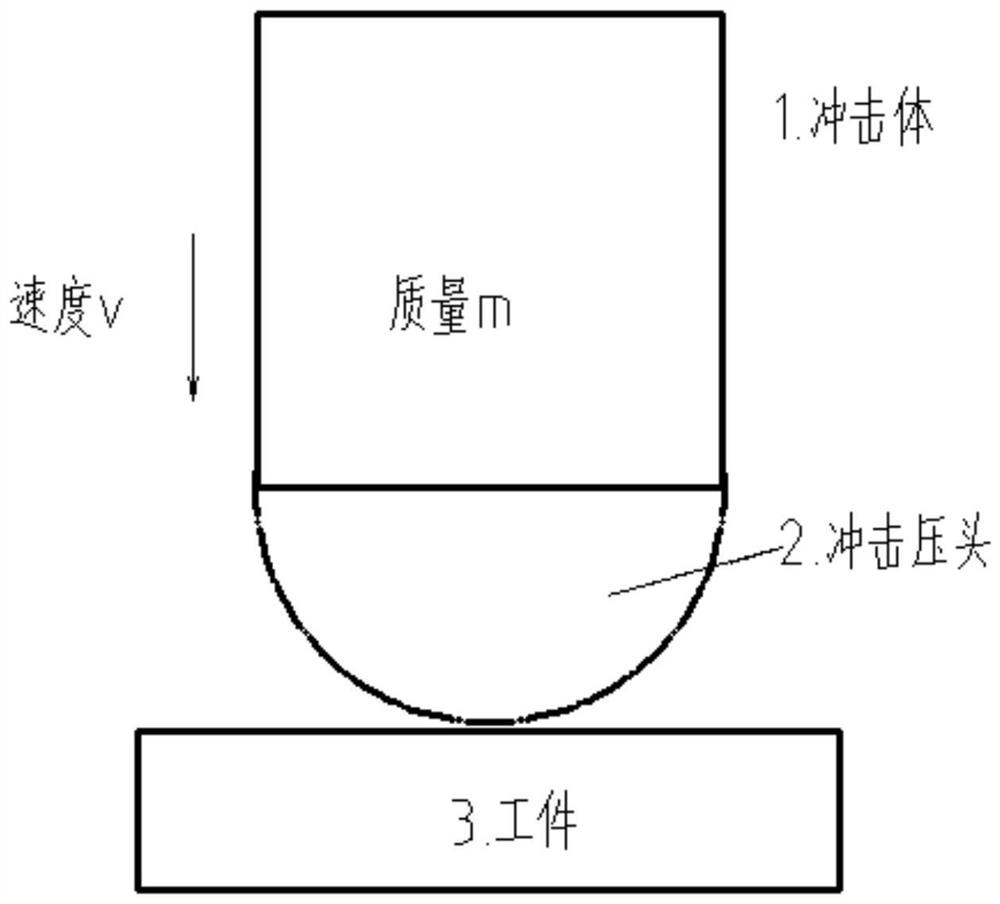

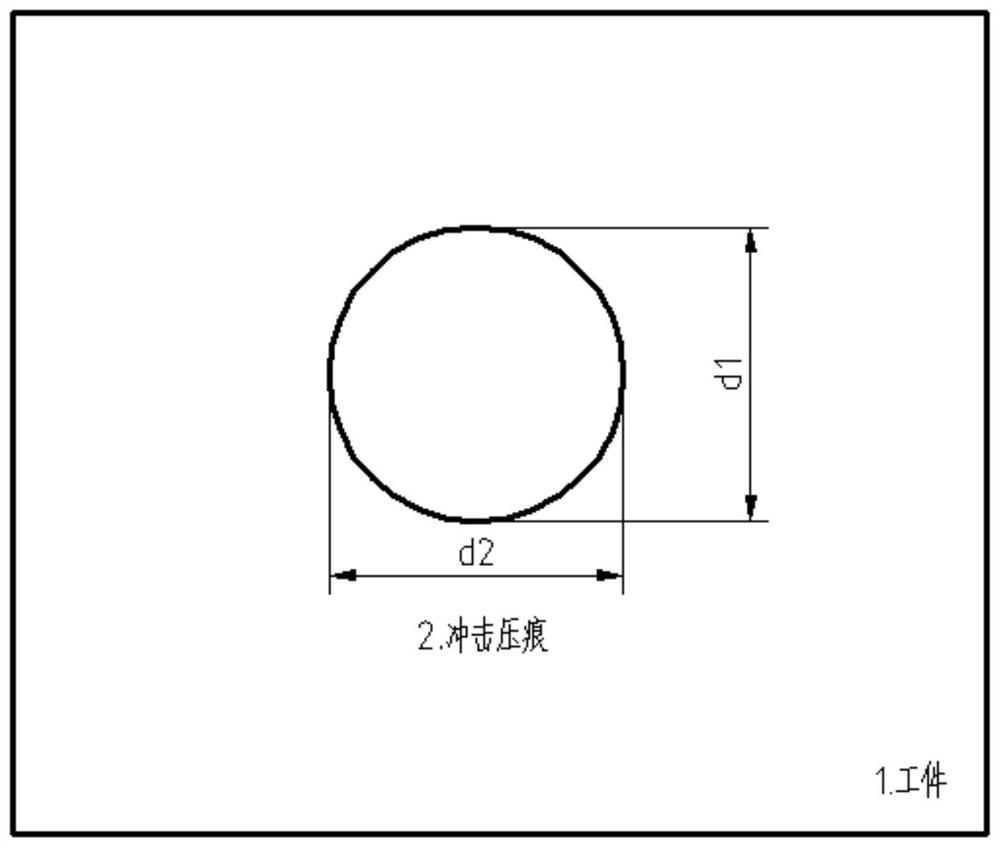

[0041] Use a tungsten carbide spherical indenter impact device with a diameter of 3mm to impact the surface of a carbon steel workpiece (size 100mm×100mm, wall thickness 8mm). The schematic diagram of the impact device is shown in figure 1 , The impact kinetic energy of the impact device is E=11J. Workpiece hardness where k is the coefficient, S is the surface area of the impact indentation, d1 = 0.639mm, d2 = 0.633mm, the coefficient k is 10, the calculated workpiece hardness is 342, see impact indentation figure 2 .

Embodiment 2

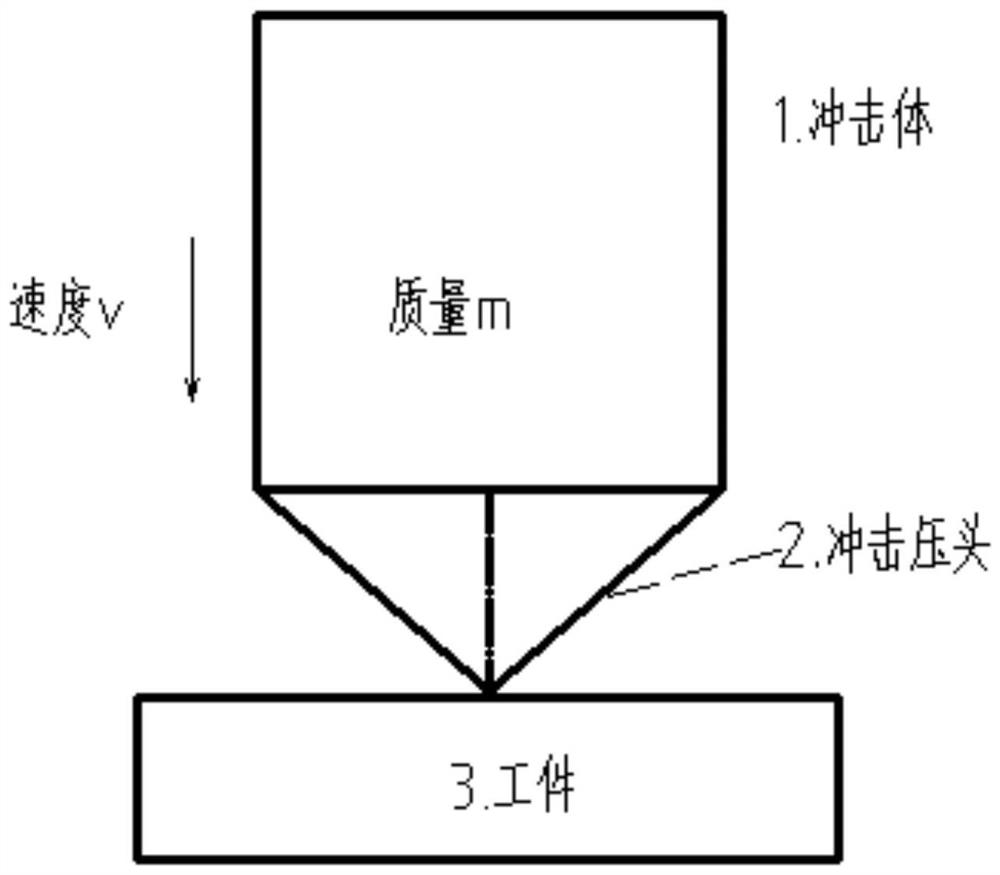

[0043] The surface of the carbon steel workpiece (size 100mm×100mm, wall thickness 8mm) is impacted by a regular quadrangular pyramidal tungsten carbide indenter with an included angle of 136° between the two opposite surfaces of the indenter. The schematic diagram of the impact device is shown in image 3 , The impact kinetic energy of the impact device is E=11J, where m is the mass of the impact body, and v is the speed when the impact body contacts the workpiece. Workpiece hardness Where E is the impact kinetic energy, k is the coefficient, S is the surface area of the impact indentation, L1=0.416mm, L2=0.418mm, the coefficient k in this example is taken as 1, and the calculated hardness of the workpiece is 117, see impact indentation Figure 4 .

Embodiment 3

[0045] The size of the plate-shaped steel workpiece is 100mm×100mm, and the wall thickness is 8mm. The workpiece is suspended and fixed by a table, see Figure 5 . In this example, the conventional Leeb hardness tester and the method of the present invention are used to test the hardness of the workpiece respectively. Both methods use the Leeb hardness tester of the D-type impact indenter to impact the surface of the workpiece. The diameter of the tungsten carbide spherical indenter of the impact device is 3mm, and the impact kinetic energy of the impact device is E=11J. The steel workpiece is impacted near the geometric center of the plate and around 10mm away from the edge. The test results of the Leeb hardness tester show that the Leeb hardness values near the center of the workpiece are 618, 617, 620, 614, and 624 (HLD), and the Leeb hardness values at 10mm from the non-clamping edge of the workpiece are 570 and 558 respectively. , 591, 550, 552 (HLD). By adopting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com