Drainage armour clamp of high voltage alternative current circuit tension resisting tower

A high-voltage AC and tension tower technology, applied in the direction of mechanical vibration damping device, etc., can solve the problems of increasing cost, increasing the dead weight of the drainage line, and discharging the drainage line, so as to reduce the project cost, shorten the length of the cross arm, and prevent the wind flash. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

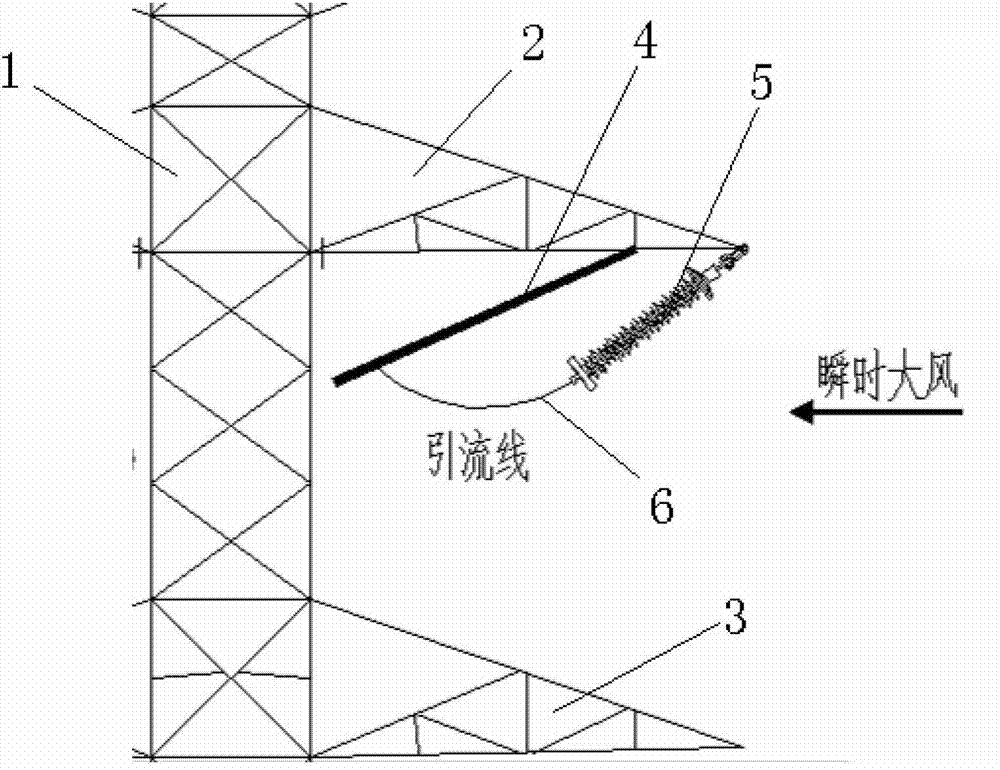

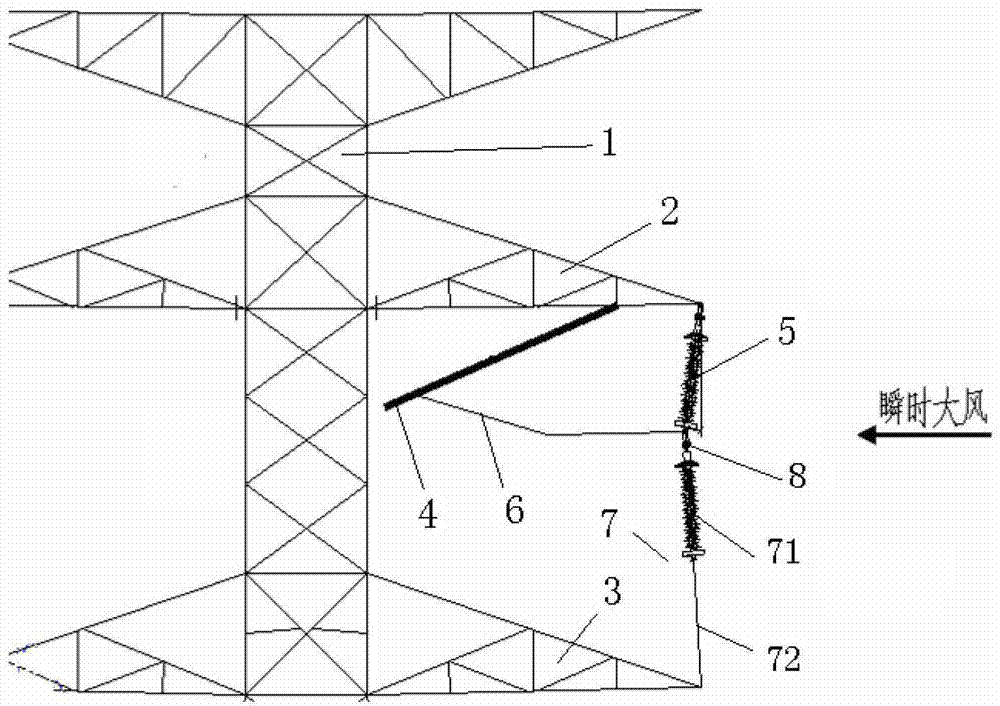

[0038] Such as figure 2 As shown, a high-voltage AC line tension tower drainage fitting provided by the present invention includes a jumper string 5, and the jumper string 5 is arranged between two tension strings 4 connected to the two ends of the drainage line 6, The upper end of the jumper string 5 is hinged with the upper cross arm 2 of the strain tower 1, and its lower end is connected with the drain wire. The lower end of the jumper string is also provided with a limit device for limiting the maximum swing angle of the jumper string. One end is hinged with the lower cross arm of the strain tower, and the other end is hinged with the lower end of the jumper string, and the maximum swing angle of the jumper string is limited to 5°-7°.

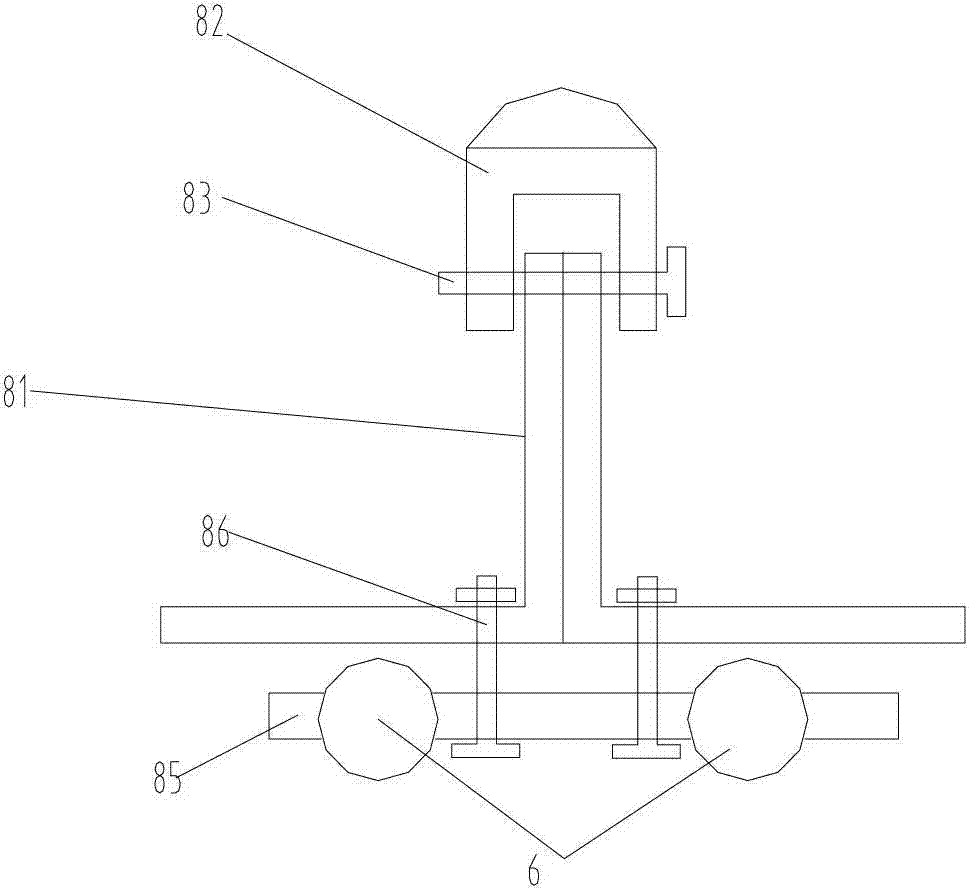

[0039] The limit device includes a limit jumper string and an elastic stay wire. The upper end of the limit jumper string is connected to the lower end of the jumper string through a connecting device, and its lower end is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com