Light-emitting diode (LED) driving power supply and LED lighting lamp

A LED driving and LED lighting technology, which is applied in the direction of electric light source, lighting device, lamp circuit layout, etc., can solve the problems of large size, large power loss of power switching tube secondary rectification circuit devices, and many electronic components, etc., to achieve Solve the effects of inconsistency, increased service life, and fewer electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

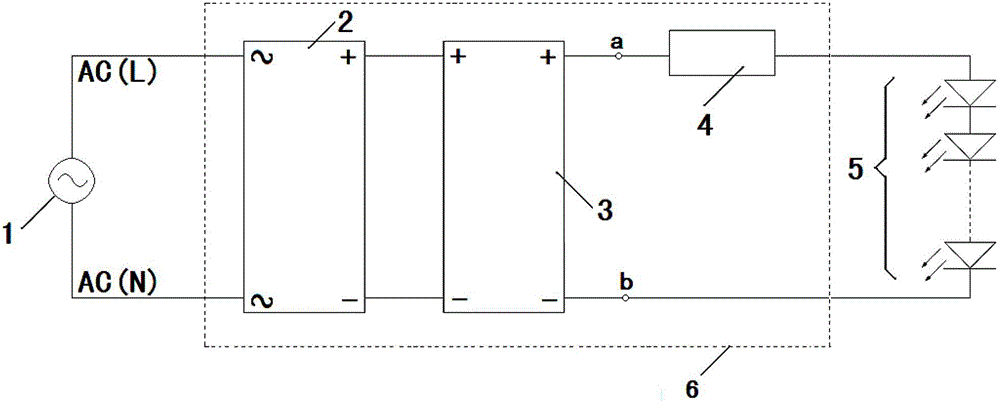

[0045] see figure 1 , in this embodiment, the LED lighting fixture includes an LED light source chip 5, an LED light source chip substrate (not shown), an LED driving power supply 6, and a lamp housing (not shown); the LED light source chip 5 is mounted on the LED light source chip substrate to form The LED lamp board is fixedly installed in the housing of the lamp.

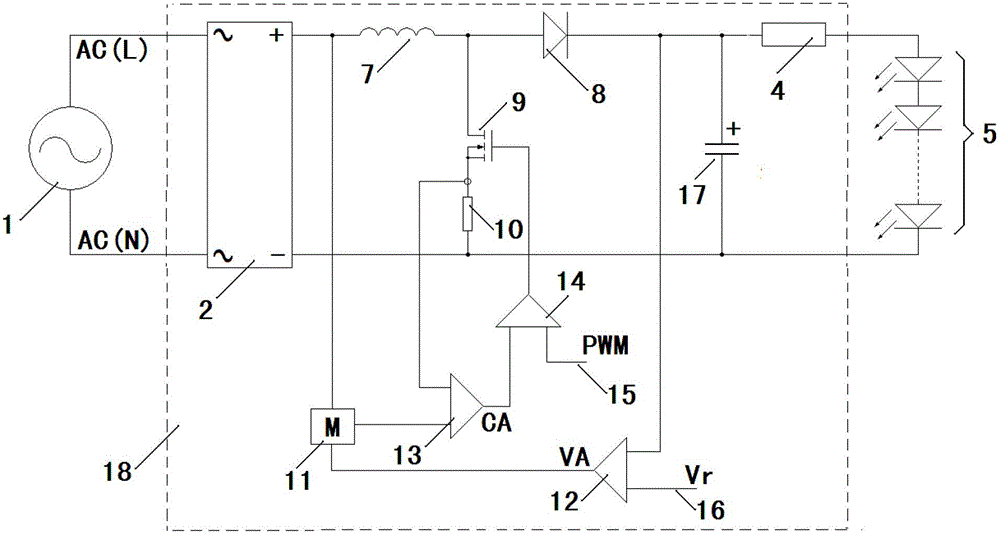

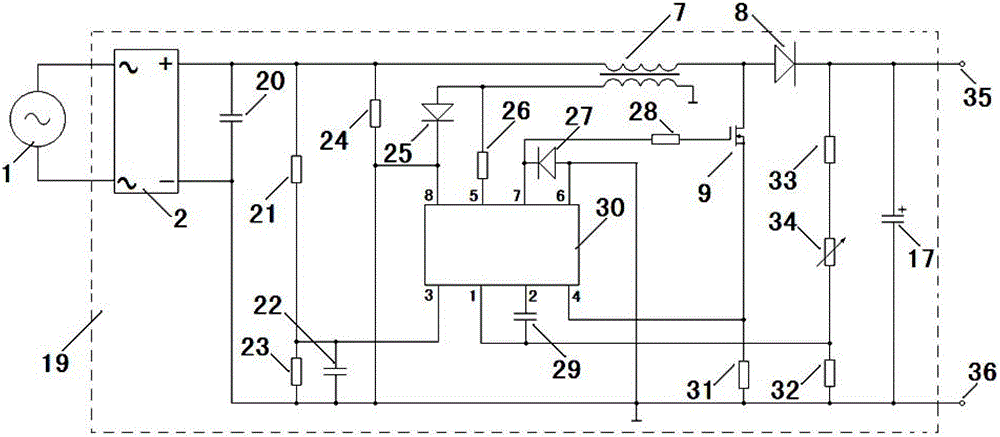

[0046] The LED driving power supply 6 of the LED lighting fixture includes a bridge rectifier circuit 2, a power factor corrector circuit 3 (referred to as a PFC circuit, and the English full name is "Power Factor Correction"), a constant current circuit 4, and an output terminal of the bridge rectifier circuit 2 Connect the input terminal of the power factor corrector circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com