Mounting system for air compressor

An air compressor and mounting system technology, applied in the field of powertrain and air spring vehicle, can solve the problems of poor vibration absorption and noise reduction, and achieve the effects of reducing vibration, avoiding winding interference, and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

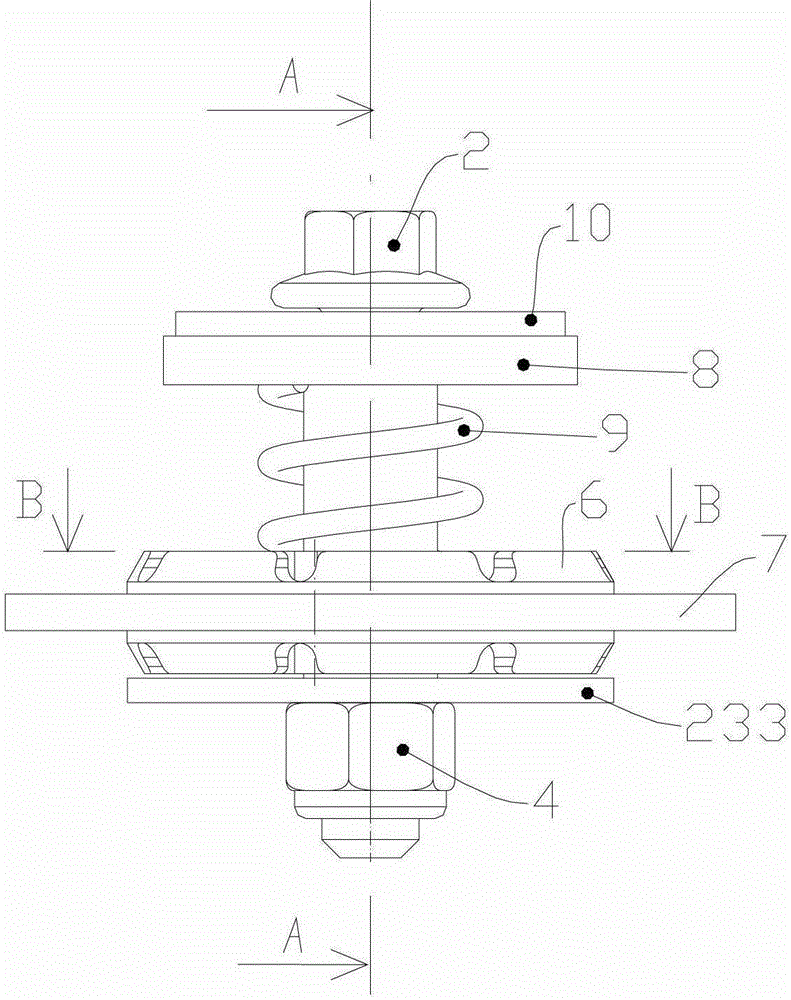

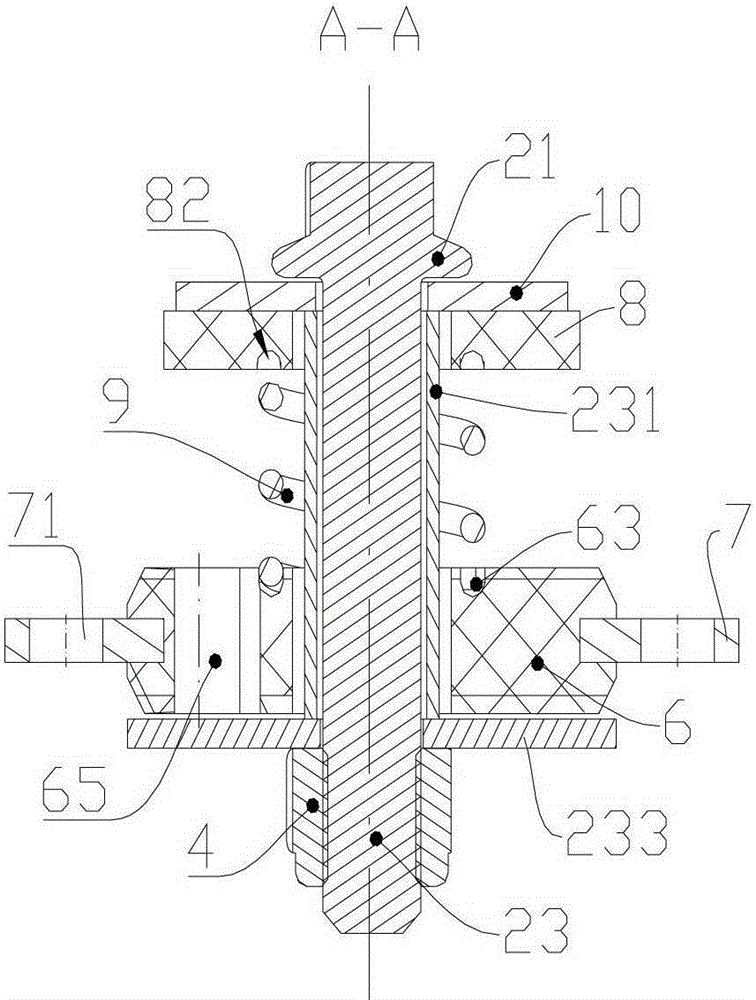

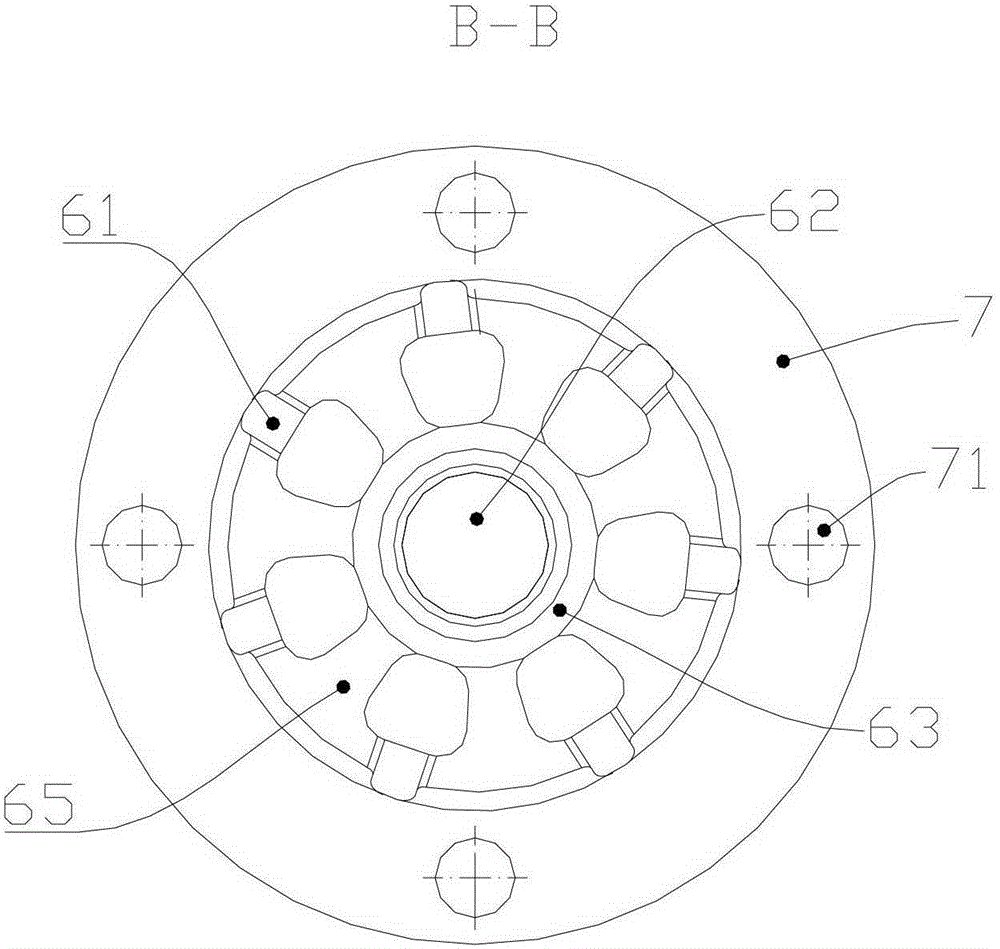

[0020] see figure 1 and figure 2 , the embodiment of the present invention provides a suspension system for an air compressor, which is suitable for an air spring vehicle using an electric air compressor, and the air compressor includes a bracket 10 . The suspension system of the air compressor of the present invention includes bolts 2 connected with the bracket 1, self-locking nuts 4 installed on the bolts 2, rubber soft seats 6 connected with the vehicle body bracket (not shown in the figure), installed on the The rubber cushion 8 on the bolt 2 and the damping spring 9 installed between the rubber cushion 6 and the rubber cushion 8.

[0021] The bolt 2 includes a head 21 and a shank 23 . The self-locking nut 4 is rotatably instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com