Toppling protection mechanism of fuel oil warming furnace

A technology of protection mechanism and heating stove, which can be applied to heating fuel, household stove/stove, liquid heating fuel, etc., and can solve the problem of wick fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

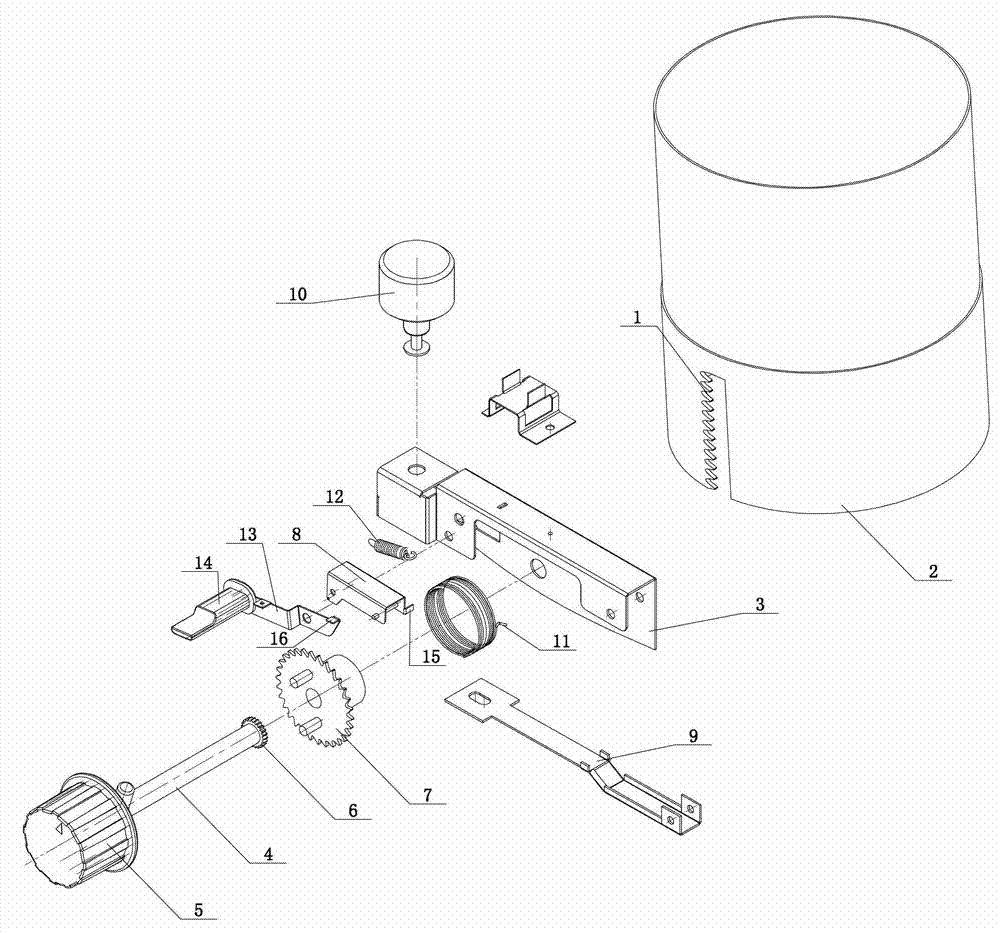

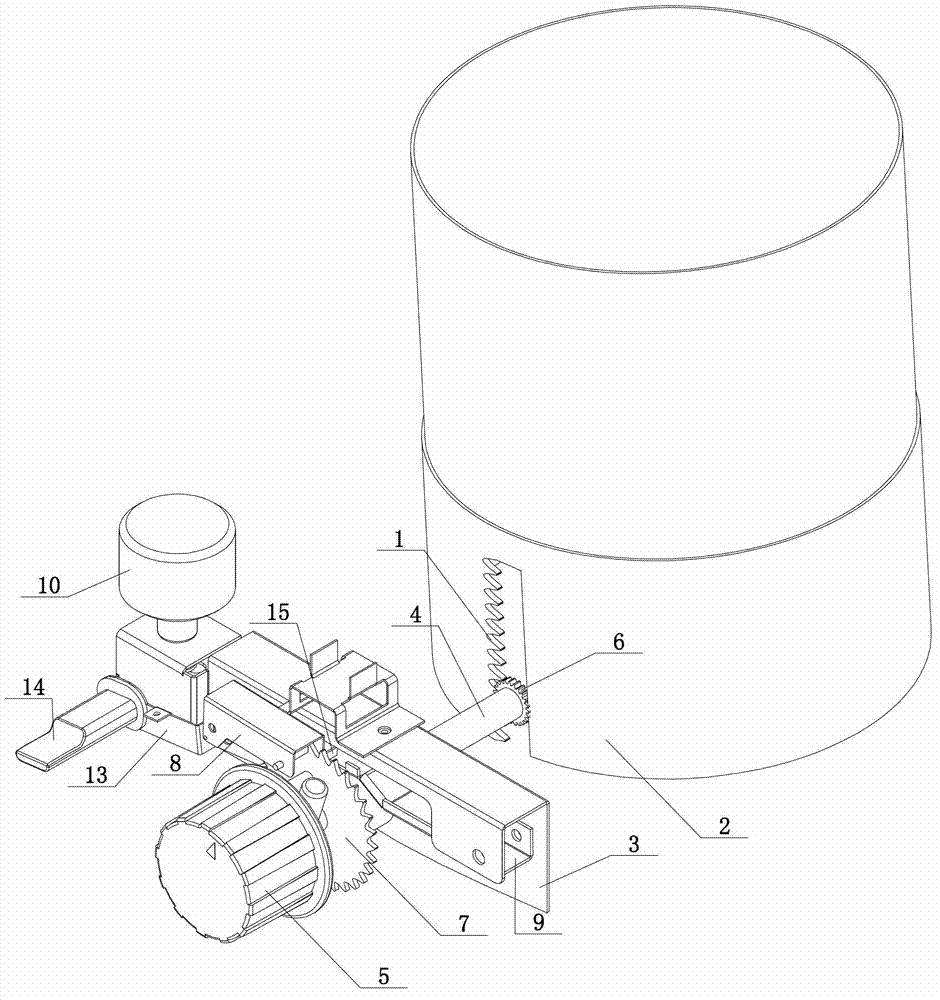

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] The dumping protection mechanism of the fuel oil heating furnace of the present invention comprises a wick bracket 2 equipped with a wick and a rack 1, a mounting frame 3, and a transmission rod 4. The transmission rod 4 passes through the mounting frame 3 and is rotatably connected with the mounting frame 3. The first handle 5 and the gear 6 are respectively installed on the two ends of the transmission rod 4 located on both sides of the installation frame 3, and the gear 6 meshes with the rack 1. It also includes a ratchet 7, a backstop 8, a first lever 9, and a dumping block 10; The ratchet 7 is installed on the transmission rod 4, and the ratchet 7 is also equipped with a first spring 11 that can make the ratchet 7 reverse; The teeth of 7 are against each other, and the backstop 8 is also equipped with a second spring 12 that can keep the other end of the backsto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com